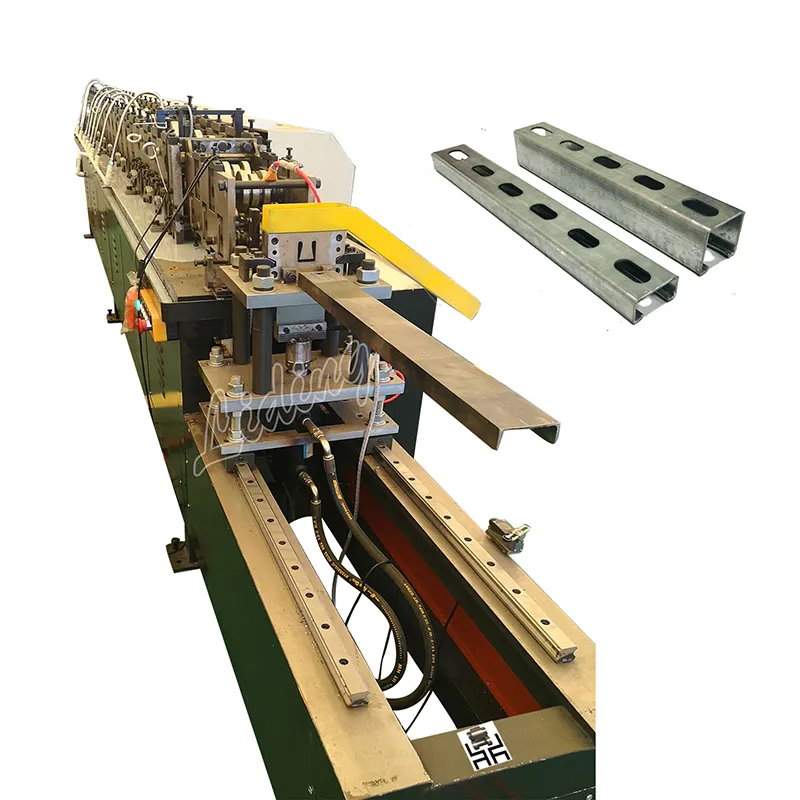

Cold Roll Forming Machine for Industrial Factory

Product details of the cold roll forming machine

Product Information

The design of Liding Machine cold roll forming machine is not just about how it looks, it’s also about how it feels and works. It is tested on defined parameters to ensure its reliable performance, longer service life & durability. It is the acquirement of customers to Liding Machine that motivates it to be more concentrated on producing finest cold roll forming machine.

Profile

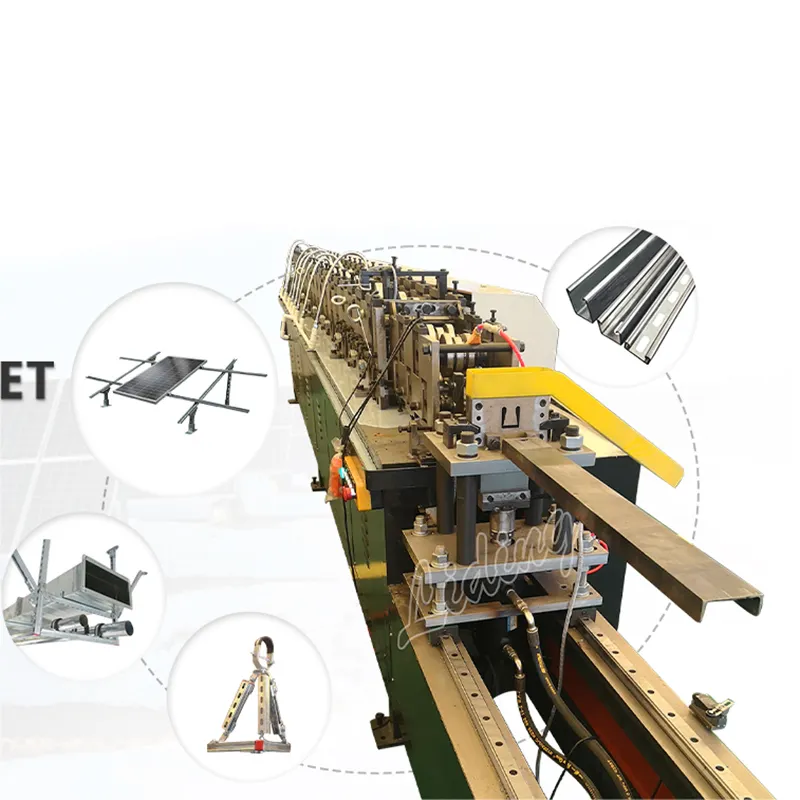

Application

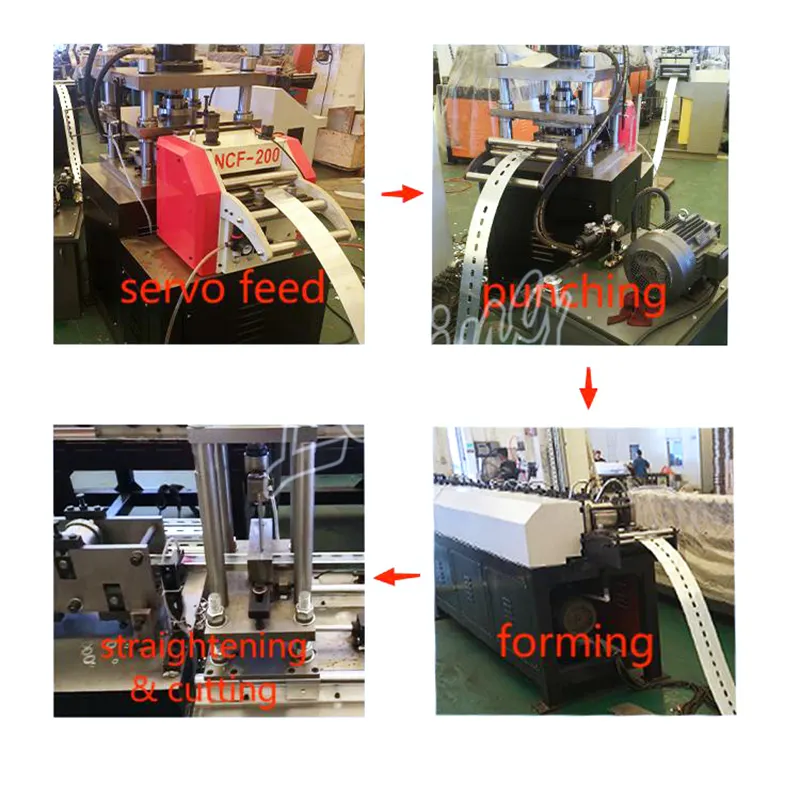

Workflow

Electric decoiling and leveling feed - servo feed - punching and punching teeth - cold roller forming - hydraulic cutting - unloading - finish

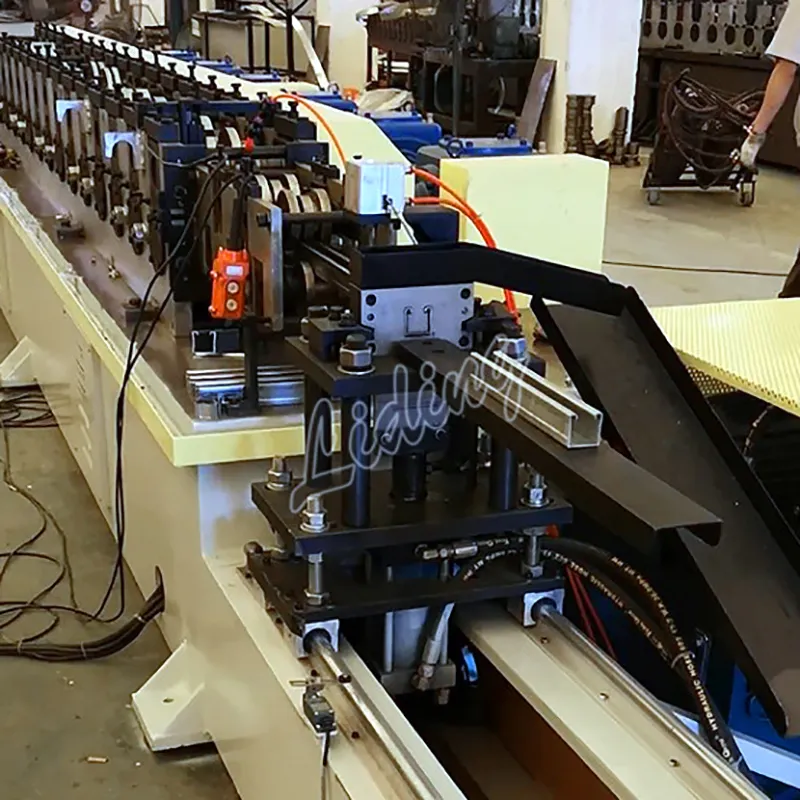

Composition of the machine

the whole line is about 24 meters long

● Electric leveling Decoiler(2T),1 set

● Servo feeder,1 set

● Hydraulic punching machine,1 set

● Punching molds (41*21, 41*41),2 sets

● Forming machine,1 set

● Hydraulic cut-off mold ,1 set

● Run-out table,1 set

● PLC control cabinet 1 set

Basic Configuration

Electric leveling Decoiler

● Bore diameter 460~520mm.

● Material width 300mm.

● Load weight 2000kg.

● Manual core expansion is used.

● With power transmission .

● Automatic control function.

NC precision electronic numerical control roller feeding machine

● Material width: 200mm.

● Material thickness: 3.0mm.

● Servo motor:AC1.8KW.

● Feeding speed: 10 meters/min.

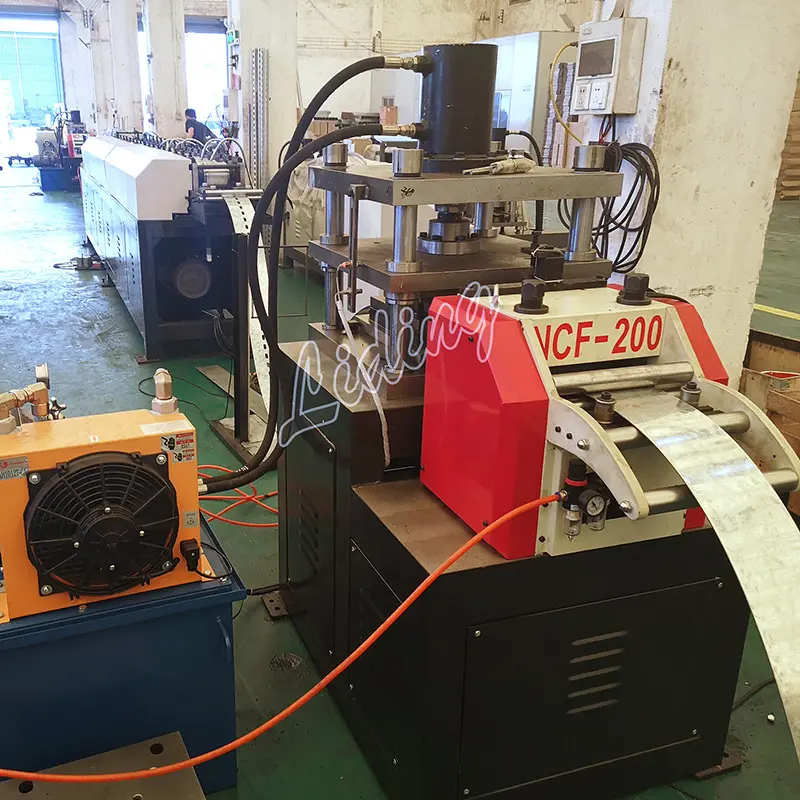

Hydraulic punching machine 1 set, punching mold 2 sets

● Hydraulic working pressure:16MPA

● Hydraulic motor:7.5KW

● Material width 102-142mm.

● Material thickness 1.5-3.0mm.

● Mold material Cr12MoV.

Basic Configuration

Molding machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:1.5-3.0mm.

● Machine can produce 41*21, 41*41 two specifications, lifting forming module replacement specifications

● Main motor power: 22kw (two motors total 22kw).

● Forming speed: 0-6m/min.

● Bearing: NJ210E Bearing

● Number of forming groups: 21 groups (14 groups for replacement specifications)

● Shaft diameter and material: ¢58mm, 45# steel.

● Tolerance of cut length: 3m+-1.5mm, (cut between hole and hole).

● Transmission: Chain, gearbox steering transmission. (Main drive reduction gearbox: BWD4).

● Control system: PLC control.

● Machine net weight: about 8 tons .

● Voltage: 380V/ 3phase/ 50 Hz.

● Dimensions of forming machine: Approx. L*W*H 7m*1m*1.4m (Frame welded with steel pipe)

● Forming roll material: Cr12MoV.

● Cutting mold material: Cr12MoV Heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● Equipped with a set of hydraulic system unit.

● With two sets of mold cut-off.

● Motor power 4 kW.

● Adopt cylinder control cut-off method.

● Adoption of non-stop cylinder jack cut-off method

Unloading

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

● Pneumatic automatic unloading is adopted.

PLC computer control box

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Automatic measurement: encoder

● Control the length and quantity with PLC. The machine automatically cuts the length and stops when the required quantity is reached.

● Length can be modified

● Control panel: push-button switches, touch screen

Product display

Company Advantage

• Foshan Liding Technology Co.,ltd's highly educated team provides a solid foundation for the development.

• Incorporated in Foshan Liding Technology Co.,ltd accumulates a wealth of industry experience and has a comprehensive marketing service network. We enjoy a good brand image and corporate image in the industry.

• In addition to the sales to major cities in the country directly, our company's products are also exported to Southeast Asia, South America and some countries and regions.

If you would like to partner with Foshan Liding Technology Co.,ltd, please leave your contact information. We will get back to you as soon as possible!