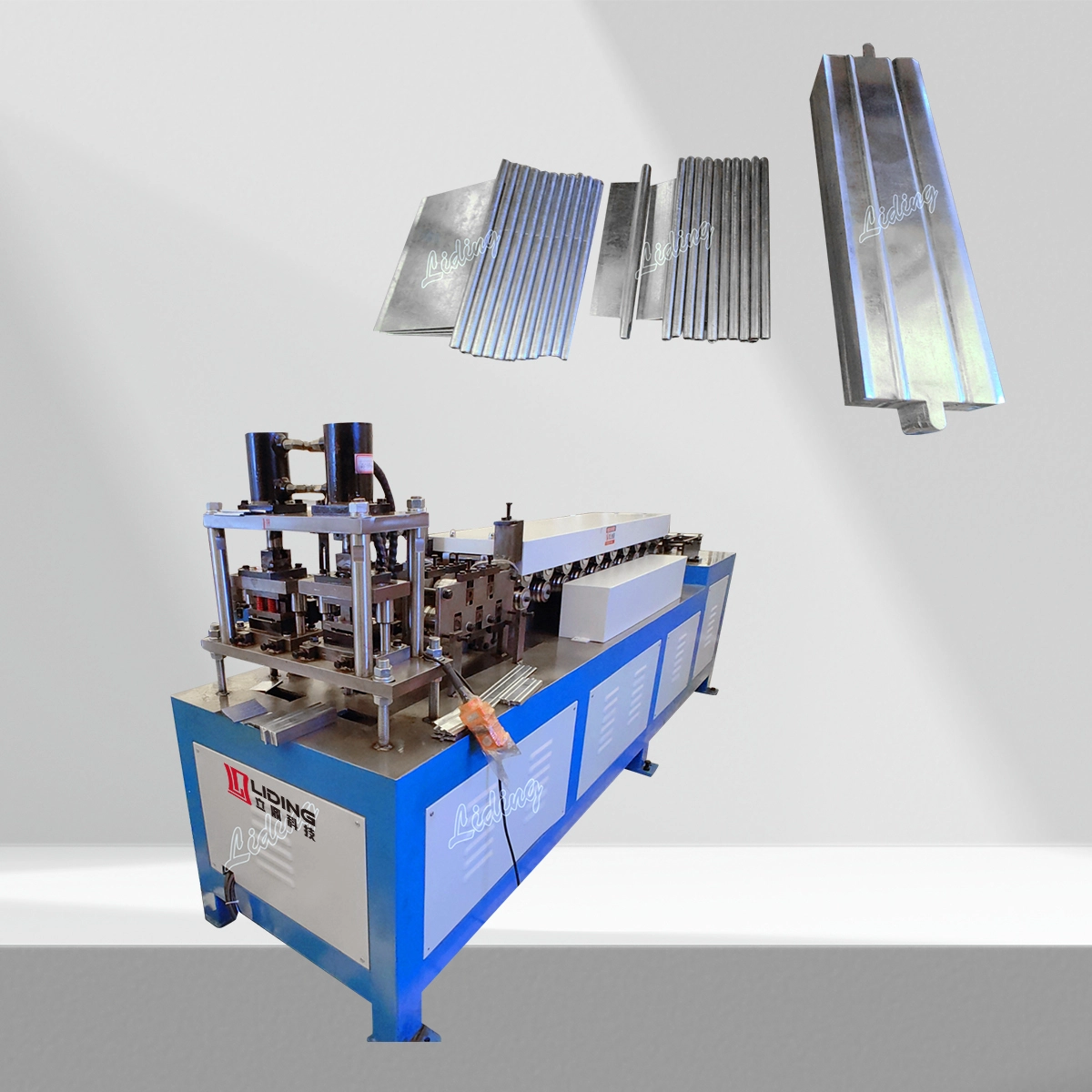

Three-in-one Fire damper blade forming machine

Electric Decoiler

Bore diameter 460~520mm.

Material width 500mm

Load weight 1500kg

Quantity: two.

Manual Expansion

Powerless transmission,with brake.

Main features

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:Blade1.0mm;Blade type 1\2\3 0.5mm

● The forming rolls of the two products are installed side by side on the same frame to produce two specifications of profiles respectively.

● Blade type 1\2\3 is notched before forming.

● The frame is welded with 100*80 pipe.

● Rolling roller 10 sets

● Rolling roller material GCr15 steel

● Rolling roller heat treatment HRC55°~57°.

● Rolling wheel bearing diameter 42mm, material 45# steel.

● Rolling roller bearing specification 6207

● Plywood thickness 25㎜

● Transmission method Chain and gear wheel

● Motor power 3 kW, K77

● Forming speed 6 m/min

Composition of the machine

● Manual Decoiler ,1 set

● Forming main machines (Internal and external ),1 set

● Hydraulic system Mold,1 set

● Electric control device (touch screen, inverter, PLC, etc.)

Cutting off parts

● With a set of hydraulic system device

● With Blade cut off mold 1 set, Blade type 1\2\3 cut off mold, 2 sets (replacement)

● Motor power 2.2kw

● Adopt cylinder control cutting method

● Cutting off by stopping the machine

Run out table

● Flat length 1 meters

● Flat table structure using square tube angle iron composition.

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Adopt Panasonic PLC, human-machine interface control and domestic inverter for speed regulation.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting length of the way

● Electronic control box adopts fully sealed ventilation and cooling device.

● Control box using fully sealed ventilation cooling device

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

Workflow

Decoiling -Punching- Cold Roll Forming - Cutting - Unloading - Finishing

Product display