Fully automated process from coil feeding, levelling, roll forming, fixed-length cutting to punching.

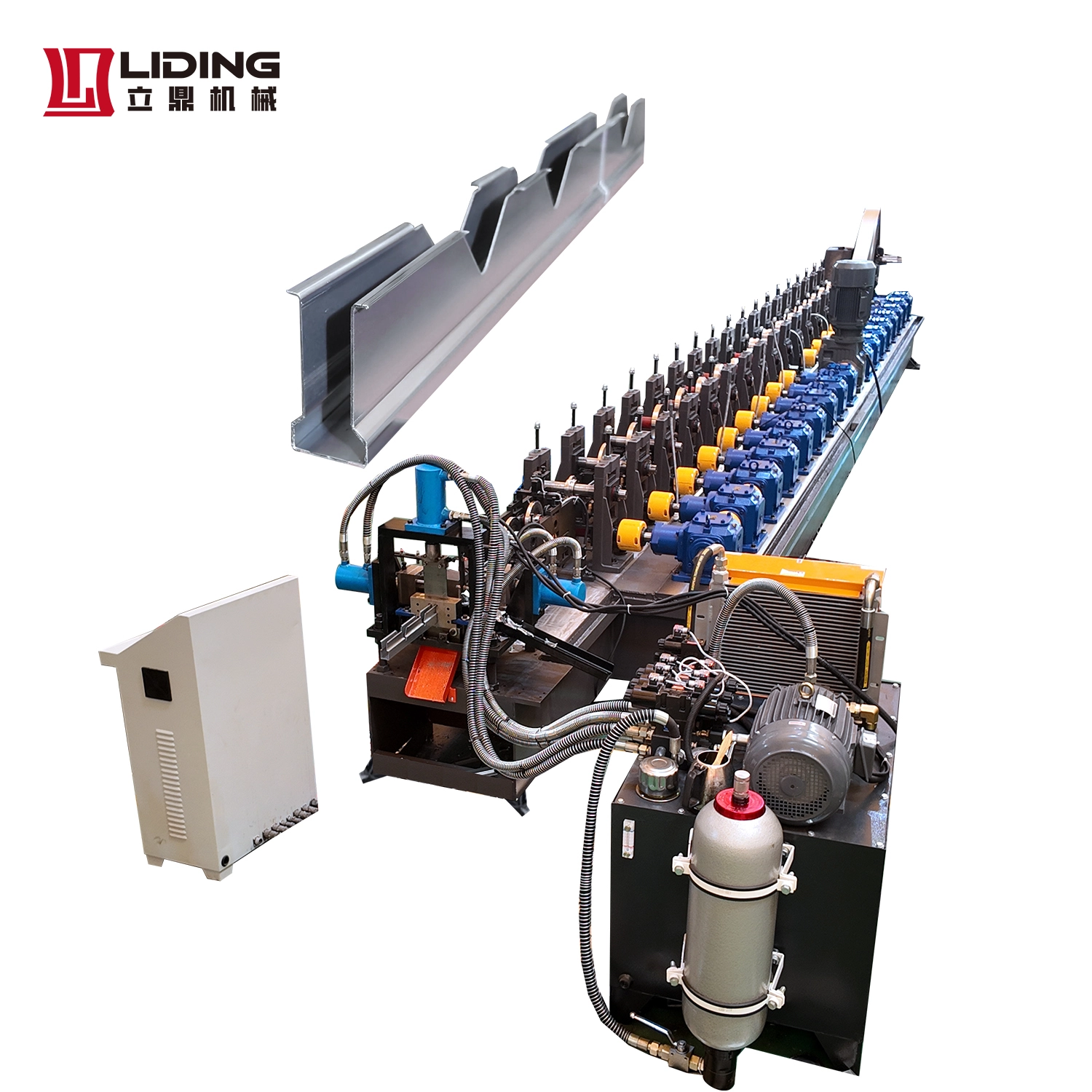

Customizable Heavy-duty Alloy Steel Formwork Forming Machine Wall Panel Production Line For Construction & Prefabrication

5.0

like

Shipping:

Support Sea freight

Place of Origin:

China

Payments:

L/C,D/A,D/P,T/T,Western Union,MoneyGram,OA

Lead Time:

1-1(sets):60(days),2-2(sets):70(days),>2(sets):To be negotiated(days)

Brand Name:

Liding

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Cutting type

Hydraulic Cutting

Use

construction

Tile Type

Q700 High-Strength Galvanised Coil

Rolling thinckness

1.0mm

Roller material

Cr12mov

Feeding width

200 mm(7.87in)

Weight

8000 kg

Warranty

1 Year

Voltage

380v

Video outgoing-inspection

Provided

Type

Forming Machine

Selling point

High-Accuracy

Product name

Panel Framework Roll Forming Machine

Place of Origin

Guangdong

Operation

Automatic

Material

Q700 High-Strength Galvanised Coil

Machinery Test Report

Provided

Key Selling Points

Long Service Life

Electric Control system

Fully Automatic PLC(imported Brand),transducer, touch panel

Dimension(L*W*H)

11m*1.2m*1.2m

Core Components

Motor, Bearing, Gear, Gearbox, PLC

After-sales Service Provided

Engineers available to service machinery overseas

Products Description

Stop Manual FabricatioStop Manual Fabrication, Start Smart Production!

This production line has been specifically developed for manufacturing high-quality, modern-design alloy steel formwork. Employing an intelligent modular manufacturing system, it enables the integrated production of dimensionally adjustable, reusable high-strength construction formwork. The line combines precision rolling, intelligent adjustment and strengthening processes, achieving automated, standardised production from raw materials to finished formwork. It meets the demands of modern construction for high-precision, reusable formwork.

Empowering Your Business:

Reduced Total Cost of Ownership: Optimised material utilisation significantly cuts labour and management

expenses, enabling rapid return on investment. Enhanced Market Competitiveness: Swiftly fulfill customer orders by producing

complex, high-value-added system formwork (e.g., climbing formwork, tunnel formwork). Strengthened Brand Reputation: Standardised,

professional product quality assists in securing major project contracts.

expenses, enabling rapid return on investment. Enhanced Market Competitiveness: Swiftly fulfill customer orders by producing

complex, high-value-added system formwork (e.g., climbing formwork, tunnel formwork). Strengthened Brand Reputation: Standardised,

professional product quality assists in securing major project contracts.

Product Specifications

Automatic Steel Formwork Machine / Formwork Panel Production Line for Formwork Factory, Bridge, Building

Core Advantages:

Producing process

Decoiling → Roll forming →Punching & Cutting→Run-out table

No | Item | Date |

1 | Decoiler | 2 ton |

2 | Roll Forming Machine | 18 STATIONS |

3 | Cutting system | 1 Set |

4 | Punching system | 2 Set |

5 | Run Out Table | 1 Set |

6 | PLC controller | PLC control system with touch screen |

One-Touch Production:

Precision Assurance:

CNC control system guarantees hole positioning and dimensional accuracy, achieving perfect

interchangeability and high reusability of templates.

interchangeability and high reusability of templates.

Robust Durability:

Heavy-duty steel frame construction and imported core components guarantee continuous, stable operation,

suited to high-intensity production environments.

suited to high-intensity production environments.

Steel Framework Forms Roll Forming Machine | ||||

Machinable Material | Q700 high-strength steel coil | Thickness(MM): 2.0 or as per customer | ||

Decoiler | Decoiler | ** Or According To Your Profile Drawings | ||

Forming Station | 18 Stands | * According To Your Profile Drawings | ||

Driving System | Chain Drive | * Gearbox Drive (Optional) | ||

Machine Structure | Wall Panel Station | *Integrated wall (Optional) | ||

Forming Speed | 12 (M/MIN) | * Or According To Your Profile Drawings | ||

Rollers’ Material | GCr 15 | * Cr12mov (Optional) | ||

Frequency Changer Brand | Panasonic | * Siemens (Optional) | ||

PLC Brand | Panasonic | * Siemens (Optional) | ||

Power Supply | 380V 50Hz 3ph | * Or According To Your Requirment | ||

Machine Color | Industrial Blue | * Or According To Your Requirm | ||

Company Profile

Foshan Liding Machinery Equipment Co., Ltd.

is established in 2014 and located in Foshan city which is the industrial center in Guangdong Province, China. Liding integrates scientific research, production and operation as one, specializing in the design and manufacture of cold-forming equipment automatic production lines, such as plug-in TDC flange machine, elliptical pipe machine,spiral duct machine, a variety of shaped cold-forming machinery, etc.

Liding provides the most professional and precise cold-forming machine machinery equipment,which has reliable quality and stable performance. A team of experienced engineers is working with PROE design software system and skilled technicians for machine production and inspection.

Liding customises stable, efficient roll forming machinery to satisfy customer requirements, aiming to developing business relations with customers from all over the world, strengthening mutual benefits and cooperation.

Company Advantages

Percentage of 100 technical service support

More than 10 professional R&D team

More than 10 professional R&D team

20 years of professional manufacturing experience in cold roll forming machines

Focus on quality and Quick response to clients

CUSTOMER VISIT

Operation-speed regulation-maintenance-type change. overseas trainer service package teachingspackage meeting 100% Welcome new and old customers to visit the factory and learn more.

Certifications

FAQ

1. who are we?

We are based in Guangdong, China, start from 2014,sell to Mid East(25.00%),Eastern Asia(20.00%),Eastern Europe(20.00%),Domestic Market(20.00%),Southeast Asia(15.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Fire damper production line,Storage Shelf roll forming machines,Flange Roll Forming machines,Shutter Door forming machine,HVAC Air Duct production line,ETC.

4. why should you buy from us not from other suppliers?

1.100 Percent technical service support 2.More than 10 professional R&D team 3.25 years of professional manufacturing experience in cold roll forming machines 4.Focus on quality and Quick response to clients

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

We are based in Guangdong, China, start from 2014,sell to Mid East(25.00%),Eastern Asia(20.00%),Eastern Europe(20.00%),Domestic Market(20.00%),Southeast Asia(15.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Fire damper production line,Storage Shelf roll forming machines,Flange Roll Forming machines,Shutter Door forming machine,HVAC Air Duct production line,ETC.

4. why should you buy from us not from other suppliers?

1.100 Percent technical service support 2.More than 10 professional R&D team 3.25 years of professional manufacturing experience in cold roll forming machines 4.Focus on quality and Quick response to clients

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

+86 181 0225 3715

Operating hours

Monday - Friday(GMT+8): 8am - 5pm Saturday: 9am - 4pm

We use high-quality materials and advanced manufacturing processes, and we are committed to providing our clients with reliable, efficient and innovative cold roll forming machinery.