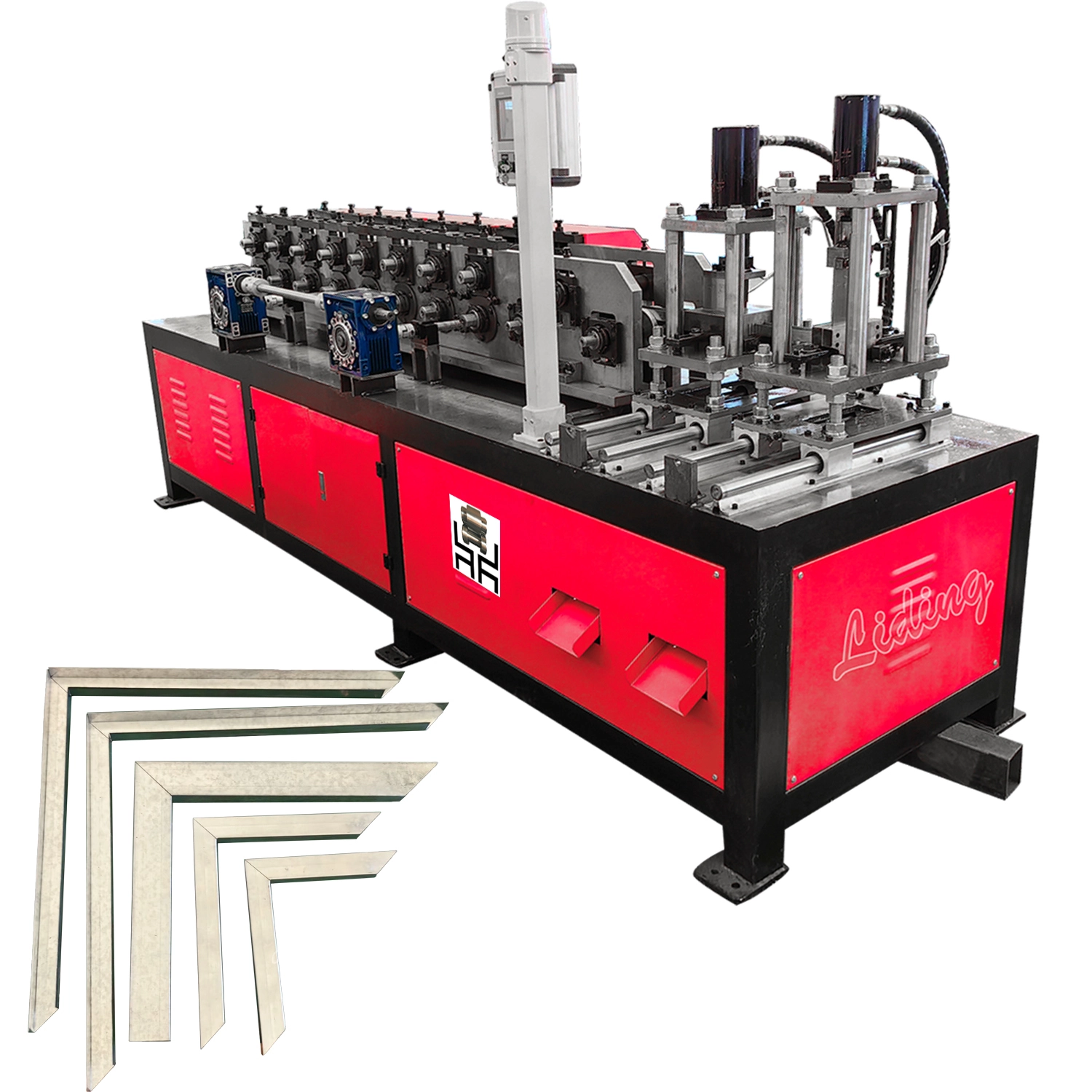

Manual width adjustment U-beam forming machine Profile

Specifications:

U30/40/50 specifications, material thickness 0.8mm

Application:

profile For the composition of the inner frame of the fire damper, with the sponge sandwiched inside

Main parameters

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:0.8mm.

● Main motor power: 4KW motor.

● Forming speed: 0-8m/min.

● Number of forming groups: 8 groups+2 Straightening rollers

● Shaft diameter and material: ¢45mm, 45# steel by tempering treatment

● Length calculation method: the length is calculated automatically by encoder.

● Length tolerance: 2000±1.0mm,

● Voltage: 380V/ 3phase/ 50 Hz.

● Dimensions of forming machine: Approx. (L) 4m * (W) 1m * (H) 1.15m

● Transmission mode: gear transmission

● Hydraulic cut-off: one set of combination cut-off mold

● Cutter material: Gr12MoV, vacuum treated. Hardness HRC62°.

● The machine can roll products width: 40-50mm; height 25mm.

● Width adjustment adopts the overall unilateral adjustment mode, using manual screw adjustment mode to control the width size.

Composition of the machine

Manual Decoiler,1 set

● Appearance size: about (L)1000mm*(W)1000mm*(H)1000mm

● Applicable outer diameter of steel coil: 1300mm max

● Applicable inner diameter of steel coil: 450mm-508mm

● Maximum width of applicable steel coil: 200mm

● Maximum bearing capacity: 1000kg

● Adopting manual core expanding and opening type tensioning, no power, with brake device.

Hydraulic equipment

● Main motor: 2.2KW

● Oil circuit board: 3 circuits with a set of pressure and flow rate adjustment valves.

● Impeller pump: 17c

● Oil tank capacity 100L

● Oil pressure cooler:Model No. OR-150

CNC automatic control equipment

● Control electric box: independent type, containing cooler.

● Cutting length calculator: 2500/pulse encoder

● This equipment comes with a set of PLC programmable control.

● This equipment comes with a set of touch-type human-machine interface to set the length, quantity, and all necessary parameters.

V.Run-out table

● the machine comes with a 4m bracket

Workflow

Decoiling- 8 Stations cold roll forming(Manual width adjustment U30/40/50) - hydraulic cutting - Run-out table

Composition of the machine:

Manual expanding core rising open decoiler, 1 set.

Cold roll forming machine, 1 set. (Manual width adjustment)

Cutting device, 1 set.

Hydraulic system, 1 set.

PLC automatic control equipment, 1 set.

Run-out table, 1 set.

Product display