Automatic Steel Channel Roll Forming Machine - Liding Machine

Products Description

Aluminumc u profile section channel roll forming machine

Customers can choose the appropriate equipment according to their own and market demand.

Application:Filter

Aluminumc u profile section channel roll forming machine details:

Feeding material: Aluminum coil

Thickness of the plate:1.0mm

Diameter of the axle:Φ48mm

Bearing Material:6208

Rolling stages:14 stages

Rolling Material : Cr12MoV

Productivity: 12m/min

Voltage:380V 50Hz 3phase

Side board:30mm

Cutting blade: Cr12MoV with heat treatment

Transmission: gearbox steering transmission

Producing process

Decoiling & Leveling → Roll forming&Straightening →Laser Marking →Crimping→punching&Cutting→Run-out table

|

No

|

Item

|

Data

|

|

1

|

Double-headed Decoiler MT-200

|

1 Ton

|

|

2

|

Roll Forming Machine

|

14 stages+5 groups straightening

|

|

3

|

Crimping mold

|

1 set

|

|

4

|

Hydraulic cutting and punching modular

|

Beijing Huade Brand

|

|

5

|

Run Out Table

|

1 m

|

|

6

|

PLC controling

|

Panasonic Japan

|

|

7

|

30W Laser Marking Machine

|

1 set

|

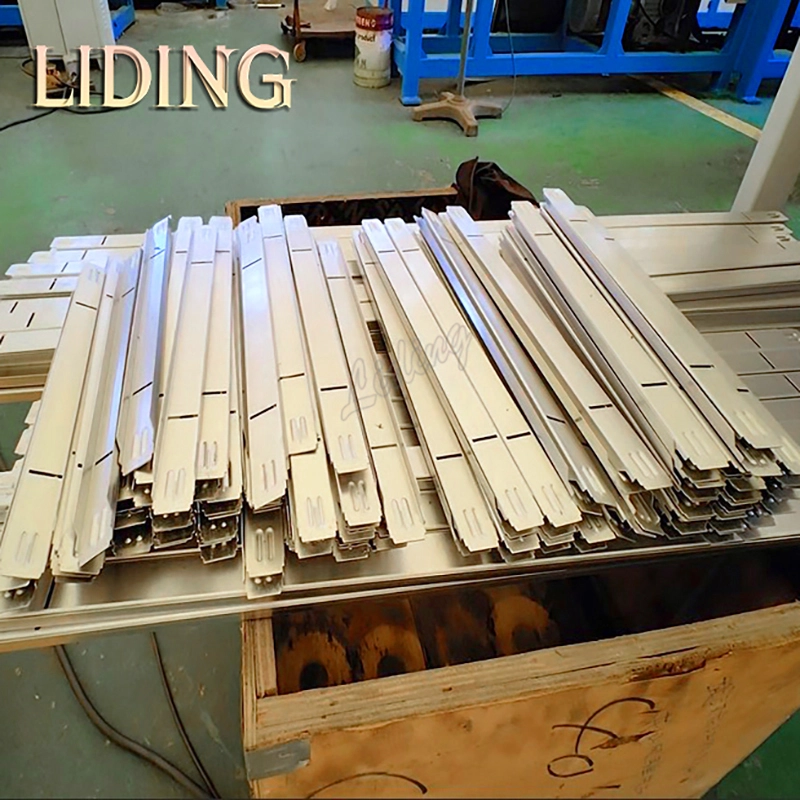

Details Images

30 years of production experience to provide customers with solutions

Non-powered double-headed decoiler MS-200

1) Applicable material roll width: 30-150mm

2)Thickness of applicable material roll: 0.3mm-1.0mm

3)Roll material load capacity: 500KG (single side)

4)Inner diameter of roll material: φ470mm-φ530mm

5)Coil outer diameter: φ1500mm

Roll forming part Mold shaft diameter:φ48mm

Shaft end bearing:6208

roll forming groups:14 groups

straightening groups:5 groups

Thickness of side plate:30mm

Feeding speed:1~12m/min Speed servo adjustment. (The overall production speed changes with the length of the product)

Electrical control system

Crimping bar mold: for stretching bar and 3x24 bar hole. Hydraulic cutting section:

(1)The components adopt Beijing Huade products and ensure the accuracy and timeliness of action execution.

(2)Punching off the mold material is excellent, long service life, easy to replace.

(3)The cross section of the product after punching is smooth and flat.

Product display