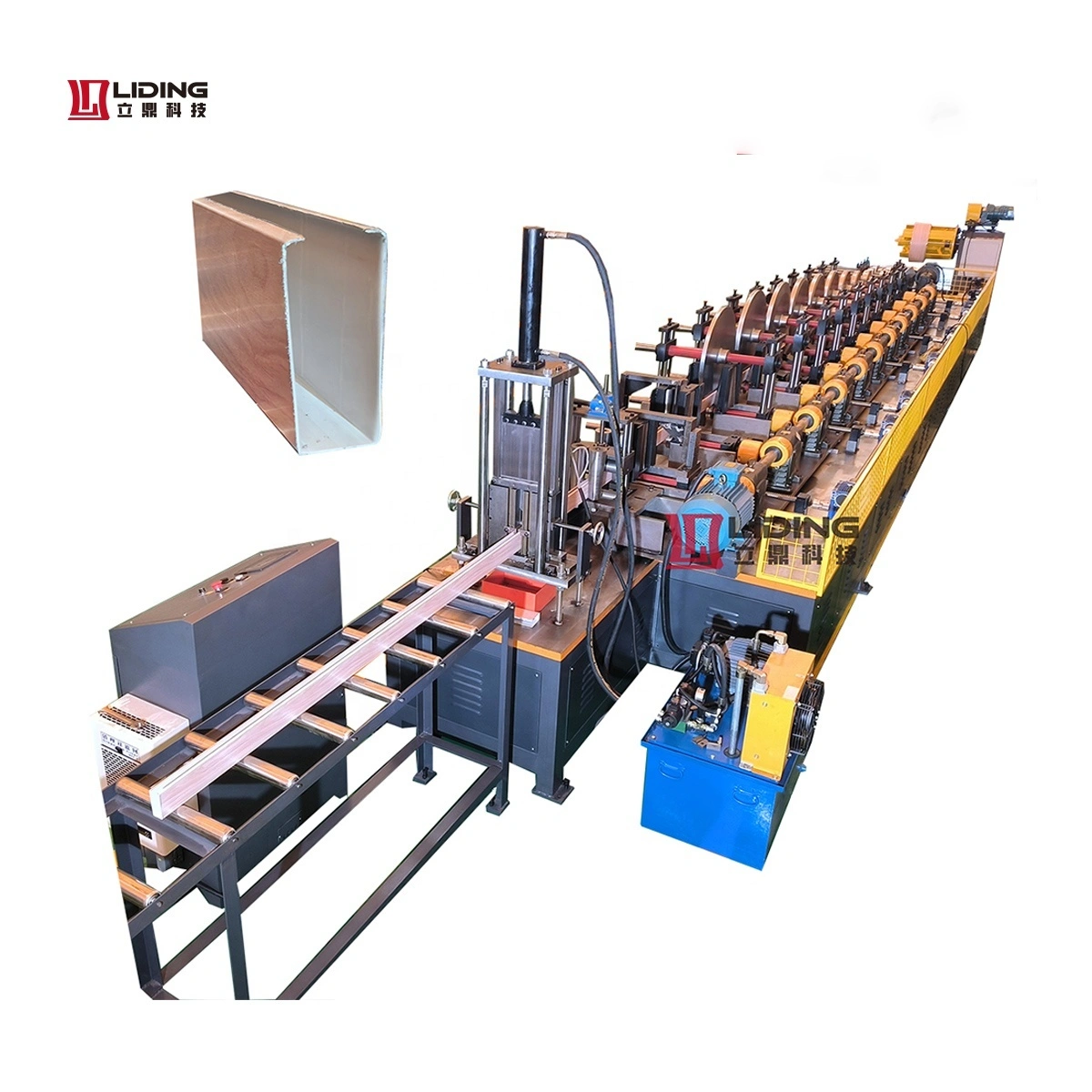

High-performance U Profile Production Open Cell Systems Roll Forming Machine For Ceiling Panels With Suspension System

5.0

like

Shipping:

Support Sea freight

Place of Origin:

China

Payments:

L/C,D/A,D/P,T/T,Western Union,MoneyGram,OA

Lead Time:

1-2(sets):80(days),>2(sets):To be negotiated(days)

Customization:

Customized logo (Min. Order: 1 sets),Customized packaging (Min. Order: 1 sets),Graphic customization (Min. Order: 1 sets)

Brand Name:

LIDING

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Keyword

Aluminum Ceiling Grid Roll Forming Equipment

PLC Brand

Delta

Motor

4/2.2 Kw

Work Pressure

12 pa

Function

for Modular Ceiling System

Color

Customer's Requirement

Certification

CE Certificate

Raw material

Galvanized coil

Weight

5000 kg

Warranty

1 Year

Voltage

380V, 440V, 220V, 220V/380V

Video outgoing-inspection

Provided

Product name

Decorative Open Cell Panel Production Line

Power

7.2KW

Place of Origin

Guangdong, China

Machinery Test Report

Provided

Key Selling Points

Automatic

Dimension(L*W*H)

8*1.2*1.4 m

Core Components

PLC, Bearing, Gearbox, motor, Gear

After-sales Service Provided

Engineers

Product Description

HVAC Grille Roll Forming Equipment

|

Serial number

|

composition

|

data

|

|

1

|

Manual Decoiler

|

Max. bearing load capacity 3000kg

|

|

2

|

Leveler device

|

1 set

|

|

3

|

Punching Machine

|

1 set

|

|

4

|

Cold roll forming integral machine

|

1 set

|

|

5

|

Cutting device

|

1 Set

|

|

6

|

Hydraulic system

|

3.7 KW

|

|

7

|

PLC automatic control equipment

|

Famous brand

|

Specification

Modular Ceiling System Roll Forming Production process

Decoiling→ Punching→Roll Forming → Hydraulic Cutting

|

Condition

|

New

|

|

Production Capacity

|

12m/min

|

|

Place of Origin

|

China,Guangdong

|

|

Brand Name

|

Liding

|

|

Voltage

|

380V 50Hz 3phases

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

Open Cell Systems Roll Forming Machine

|

|

Roller material

|

GCr15 steel

|

|

Cutting blade material

|

CR12mov

|

|

Transmission

|

Gear

|

Suspended Ceiling Panel Roll Forming Machine Main parameters

1 Main motor power 4KW

2 Transmission form Gearbox

3 Rolling speed12M/min

4 Maximum feeding width 600mm

5 Rolling material GCr15 steel

6 Rolling heat treatment hardness HRC58-62

7 Roller shaft material, diameter 50mm, 45# steel

2 Transmission form Gearbox

3 Rolling speed12M/min

4 Maximum feeding width 600mm

5 Rolling material GCr15 steel

6 Rolling heat treatment hardness HRC58-62

7 Roller shaft material, diameter 50mm, 45# steel

Company Profile

Foshan Liding Machinery Equipment Co., Ltd.

is established in 2014 and located in Foshan city which is the industrial center in Guangdong Province, China. Liding integrates scientific research, production and operation as one, specializing in the design and manufacture of cold-forming equipment automatic production lines, such as plug-in TDC flange machine, elliptical pipe machine,spiral duct machine, a variety of shaped cold-forming machinery, etc.

Liding provides the most professional and precise cold-forming machine machinery equipment,which has reliable quality and stable performance. A team of experienced engineers is working with PROE design software system and skilled technicians for machine production and inspection. Liding customises stable, efficient roll forming machinery to satisfy customer requirements, aiming to developing business relations with customers from all over the world, strengthening mutual benefits and cooperation.

Company Advantages

Percentage of 100 technical service support

More than 10 professional R&D team

More than 10 professional R&D team

20 years of professional manufacturing experience in cold roll forming machines

Focus on quality and Quick response to clients

CUSTOMER VISIT

Operation-speed regulation-maintenance-type change. overseas trainer service package teachingspackage meeting 100% Welcome new and old customers to visit the factory and learn more.

Packing & Delivery

Main machine,motor ,pump and control box are packaged by plastic paper.

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A3: We can provide the technical offer with FOB, CFR, CIF and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. What's your payment terms ?

A4: 40% as the deposit in advance, 60% as the balance payment after your inspect the machine well and before delivery. After we get down payment, we will arrange production.

Q5. How to get a quotation?

A5: 1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Q6. What is the after- sale service?

A6: 1. The warranty is 12 months after the client receives the machine.

2.Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free.

3. We offer technical support for the entire life of our machines.

4. We can send our technicians to install and train the workers in the clients' factories with extra cost.

5.After the quality guarantee period, only charge the production cost of the spare parts.

Q7. Can you provide some spare parts?

A7: Yes, of course you can. Fast wearing parts will be sent to you together with the machine.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

+86 181 0225 3715

Operating hours

Monday - Friday(GMT+8): 8am - 5pm Saturday: 9am - 4pm

We use high-quality materials and advanced manufacturing processes, and we are committed to providing our clients with reliable, efficient and innovative cold roll forming machinery.