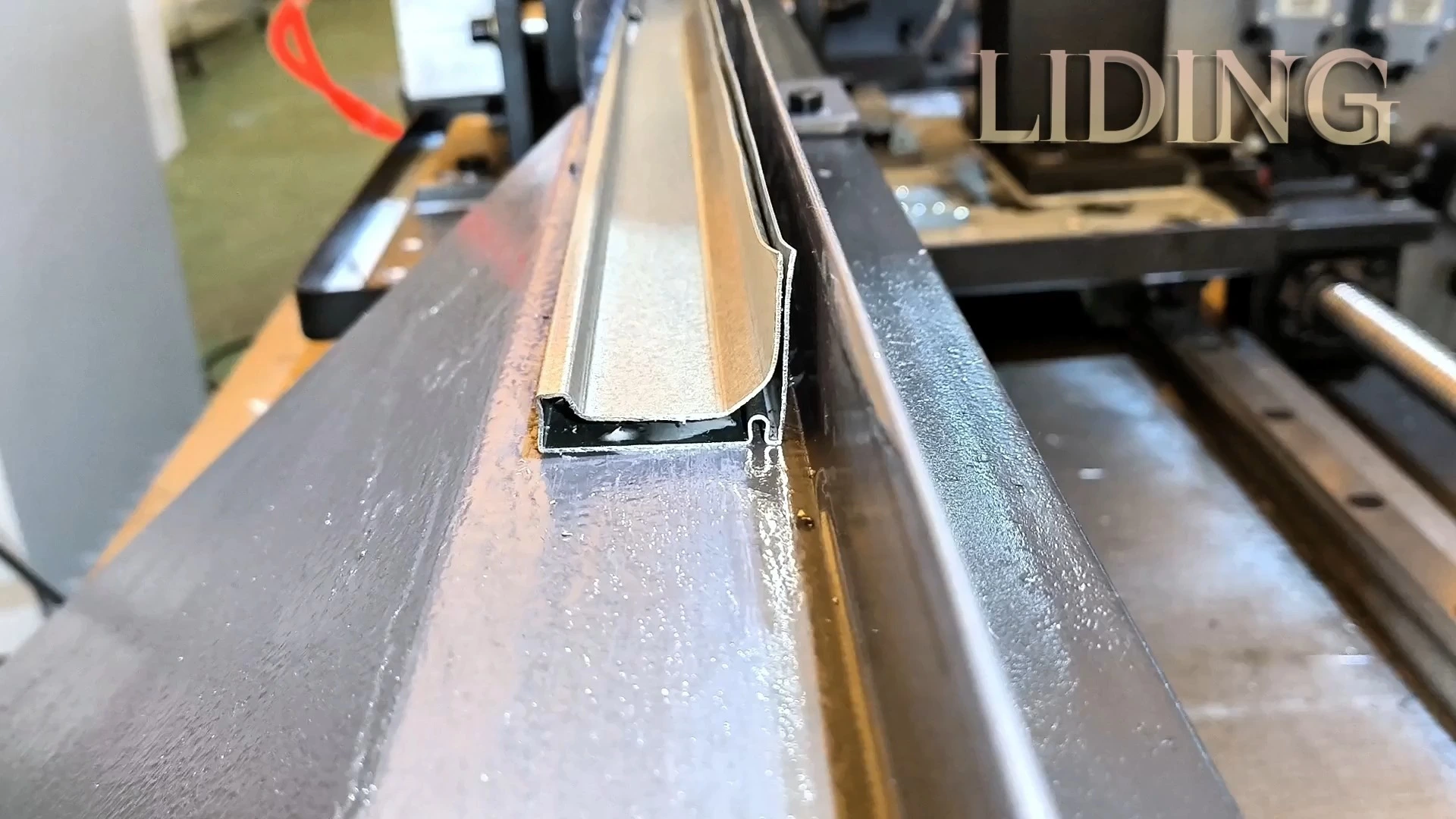

TDC flange roll forming machine

Application: For air duct

TDC flange roll former is widely used for manufacturing TDC-20mm, TDC-30, TDC-40 wide side on frame flange etc.

Custom TDC flange profiles can be offered on request. The cutting system is automatic cutting with high cutting speed up to 6-10m/min.

Youtube Video List

Main parameters

tdc flange forming machine details

① Feeding material: galvanized steel

② Feeding Thickness : 0.8-1.0mm

③ Productivity: 0-10m/min

④ Fly cutting with servo motor

⑤ Sawing Cutting

⑥ Forming machine size: approx. L*W*H 7m*0.8m*1.2m

⑦ Machine net weight: approx. 3.5 tons

⑧ Machine table:welded with 100*80 square tube

⑨ Side plate thickness:30mm

⑩ Main motor power:7.5kw

⑪ Rolling stages:22stages+ 5 rollers for straightening

⑫ Shaft diameter : ¢42mm

⑬ Shaft material:45# steel,quenched and finely ground outer circle

⑭ main bearing material :6207

⑮ Roller material: Cr12mov steel

⑯ Control systerm: PLC control system with touch screen,Cooling Fan

⑰ Roller driven type:GearBox transmission-RV Reducer

⑱ Voltage: 380V/ 3phase/ 50 Hz

Producing process

Decoiling → Feeding → Roll forming →Circular steel sawing-off →Run-out table