Steel Door Roll Forming Machines - Liding Machine

Products Description

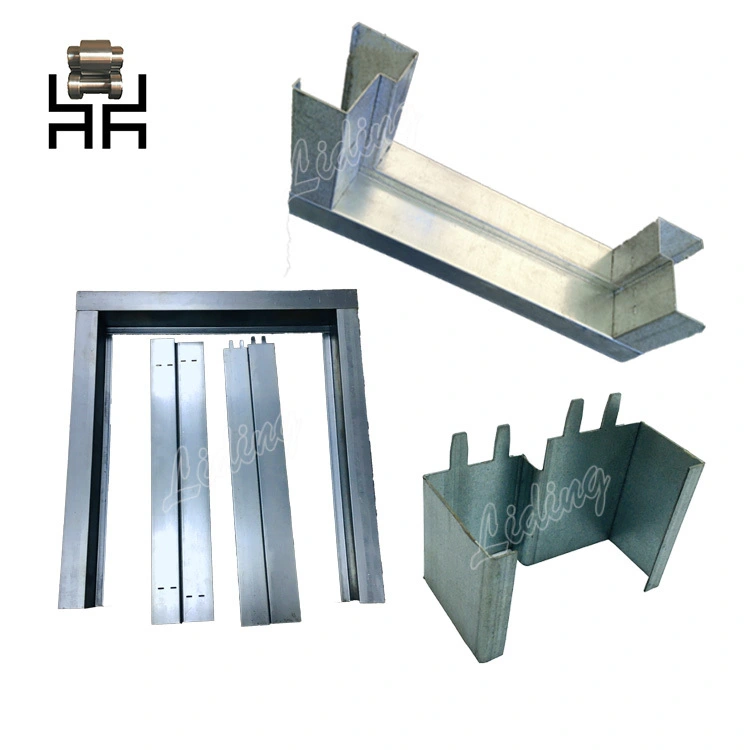

Fireproof Metal Steel shelf Door Frame Making Machine cold roll forming machine:The biggest advantage of the door frame forming machine lies in continuous non-stop operation, high-speedproduction, and unified product standards, because the plate type of the door frame is more complex, the traditionabending machine processing is time-consuming and laborious, more dependent on manual, resulting in higproduction cost. Cold forming machine solves this problem, making the door frame processing become simple, hasbeen recognized by a number of well-known enterprises in the market.

Product Specifications

Upright Window Metal Steel shelf Door Frame Making Machine cold roll forming machine details:

● Feeding material: aluzinc/galvanized steel/colored steel coil/or as customer request

● Material thickness: 0-1.2mm

● Main motor power: 5kw

● Number of molding groups: 22 groups+ 5 groups Straighten

● Cutting blade: Cr12MoV with heat treatment

● Main frame:steel plate welding

● Side plate thickness:30mm

● Shaft diameter and material: ¢48mm, 45# steel with quenched and finely ground

● Control systerm: PLC control system with touch screen

● Roller driven type:Chain & gear transmission

Producing process

Decoiling → Roll forming →Punching & Cutting→Run-out table

|

No

|

Item

|

Date

|

|

1

|

Manual Decoiler

|

2 ton

|

|

2

|

Roll Forming Machine

|

1 set

|

|

3

|

Right Punching Mold

|

1 Set

|

|

4

|

Left Punching Mold

|

1 set

|

|

5

|

Straight Cutting Mold

|

1 set

|

|

6

|

Run Out Table

|

2 m

|

|

7

|

PLC controller

|

PLC control system with touch screen

|

Details Images

25 years of production experience to provide customers with solutions

Product display