Fireproof Door frame forming machine

Application:

This machine can produce different profiles for assembling door frames.

This machine 3 in 1 produces different profiles with three different cut-off molds.

One for direct cutting, one for punching and cutting, and the other for designing specific molds for cutting.

Application

This machine can produce different profiles for assembling door frames.This machine 3 in 1 produces different profiles with three different cut-off molds. One for direct cutting, one for punching and cutting, and the other for designing specific molds for cutting.

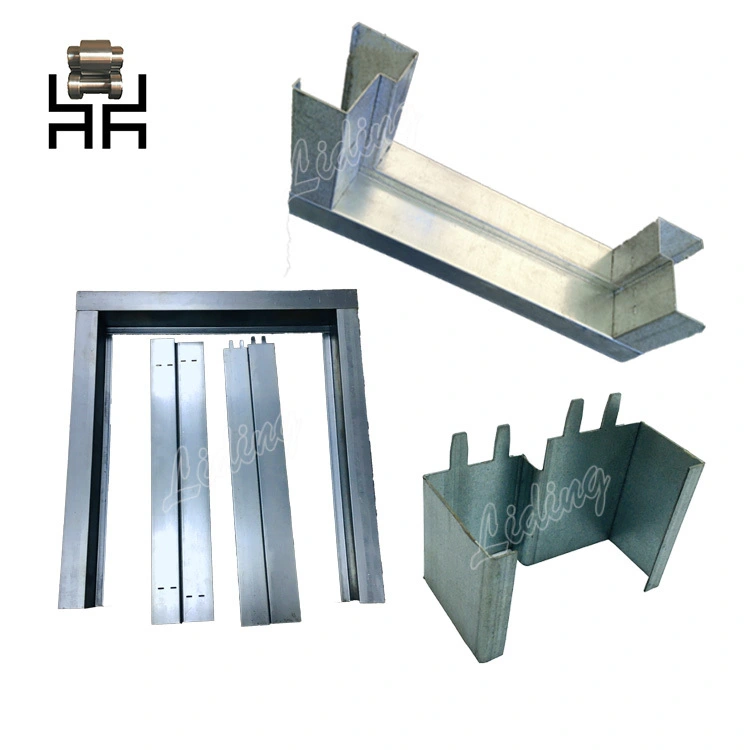

Profile

Workflow

Decoiling - Cold Roll Forming - Punching Mold Left - Punching Mold Right - Straight Cutting Mold - Finish

Composition of the machine

● Manual Decoiler,1 set

● Forming machine,1 set

● hydraulic cut-off mold,3 set

● PLC control cabinet,1 set

Main parameters

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 250mm

● Load weight 1300kg

● Quantity: One.

● Manual Expansion

● Powerless transmission,with brake.

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 1.0-1.2mm

● Main motor power: 7.5kw

● Molding speed: 6-8m/min

● Number of forming groups: 22 groups+ 5 groups Straighten

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 3 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of forming machine: approx. L*W*H 7m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Cutting off parts

● One set of hydraulic system, hydraulic motor 4KW, three stations cylinders

● 2 sets of mold frames, 2 sets of punching molds ( exchange ), 1 set of waste cut-off molds

● Mold material: CR12MOV,Processing hardness HRC60°-62°

● Adopt online encoder to detect the stopping and cutting.

Run out table

● Flat length 2 meters

● Flat table structure using square tube angle iron composition.

● Manual Unloading

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● Length of the use of internal control encoder length counting method

● Electronic control box adopts fully sealed ventilation cooling device.

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

● Voltage: 380V 50Hz

Product display