Z Purlin Roll Forming Machine Liding Machine Brand From China

Company Advantages

· z purlin roll forming machine manufacture adheres to the standard process operation.

· Quality is what Liding Machine product can do for customers.

· With great economic benefits, we are confident that the product market has broad prospects.

Product Description

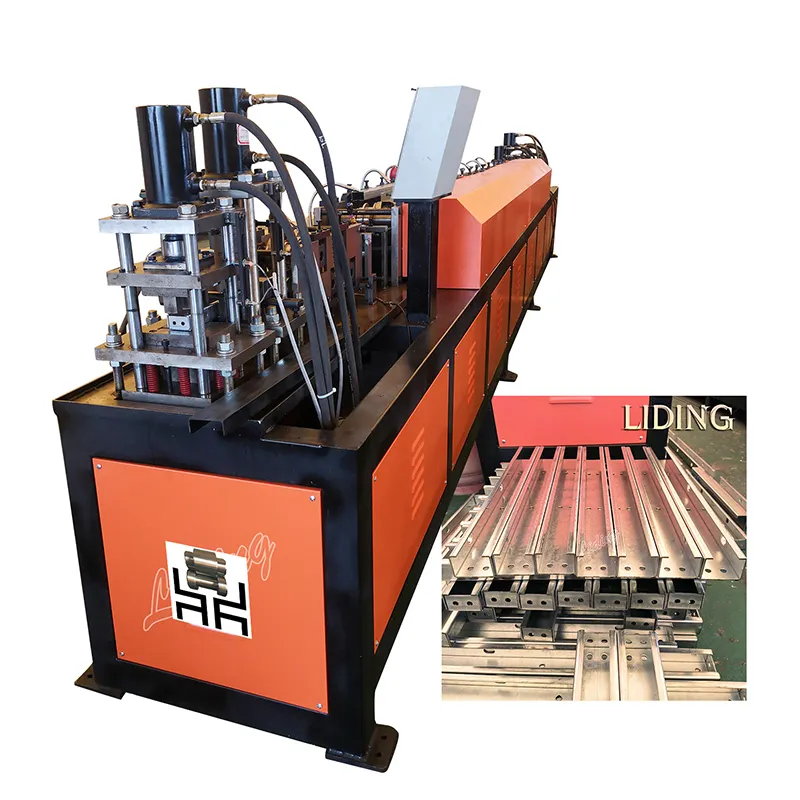

C Profile Air Blower Base roll forming machine

2-in-1 C profile machine: 2 profile production available as an option

Production process

Powerless uncoiling - servo flat feed -hydraulic punching round hole & punching square hole mold (4 sets), cut off the tail material - cold roll forming - cut off - cut off folding - finish

|

Serial number

|

composition

|

data

|

|

1

|

Manual Decoiler

|

Max. bearing load capacity 2000kg

|

|

2

|

Servo leveling feeder

|

Feeding speed: 15 meters / min

|

|

3

|

Hydraulic punching machine

|

25-ton cylinder hydraulic station with a power of 7.5kw

|

|

4

|

Punching mold, 4 sets

|

Mold material CR12MOV

|

|

5

|

Tail material cutting mold

|

1 set

|

|

6

|

Cold roll forming machine

|

15 stations

|

|

7

|

Forming and cutting mold

|

material Cr12MOV

|

|

8

|

Cutting and folding mold

|

material Cr12MOV

|

|

9

|

Hydraulic system

|

7.2KW

|

|

10

|

PLC automatic control equipment

|

Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

|

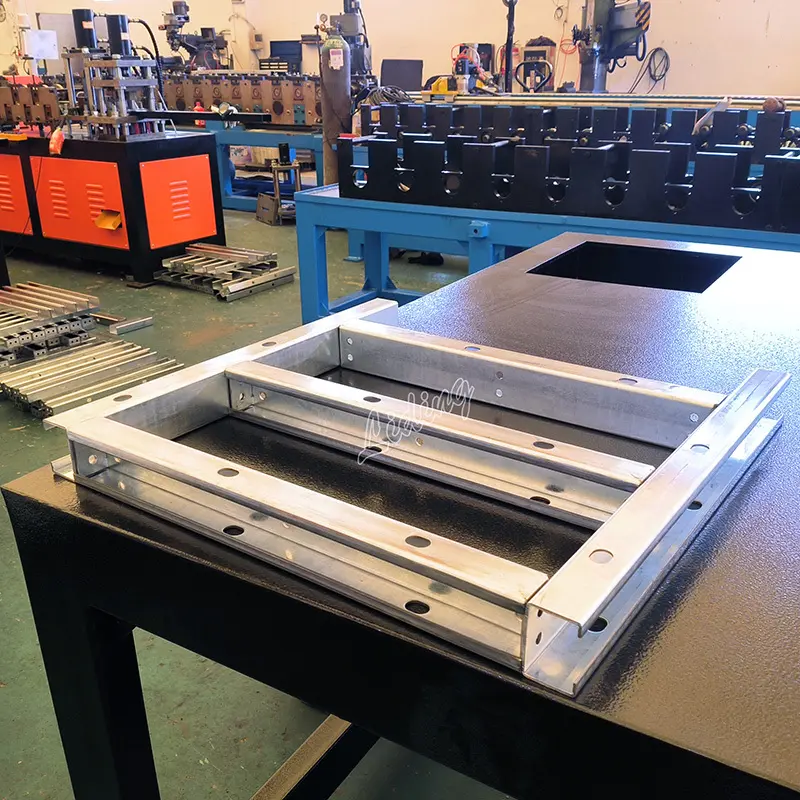

Application

Machine-produced profiles for blower bases.

Specification

|

Condition

|

New

|

|

Production Capacity

|

0-8m/min

|

|

Place of Origin

|

China,Guangdong

|

|

Brand Name

|

Liding

|

|

Voltage

|

380V 50Hz 3phases

|

|

Dimension(L*W*H)

|

6000*800*1200mm

|

|

Weight

|

4000kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Rolling thinckness

|

2.0-2.5mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

C Profile Air Blower Base roll forming machine

|

|

Roller material

|

cr12mov

|

|

Cutting blade material

|

CR12mov

|

|

Servo motor

|

7.5kw+7.5kw

|

|

Transmission

|

Chain & gear transmission.

|

Basic Configuration

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 300mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

● The main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counts the length of the way

● Electronic control box adopts fully sealed ventilation cooling device.

● Adopt shutdown cut-off mode

NC numerical control Leveling & feeding machine

● Material width: 200mm

● Maximum thickness of material: 2.5mm

● Flat feed shaft 11 rollers

● Servo motor: AC1.5KW

● Feeding speed: 15 meters / min

Punching mold,4set

● Width of material: unspecified

● SMaterial thickness 2.0-2.5mm

● Mold material CR12MOV

● Hydraulic system: a set of 25-ton cylinder hydraulic station with a power of 7.5kw;

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 0-2.5mm

● Main motor power: 5kw

● Molding speed: 0-8m/min

● Number of molding groups: 15 groups

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

Cutting off parts

● Adopt online fiber optic detection to cut off the machine.

● Cut off mold 1 set, material Cr12MOV

● Cutting and forming mold 1 set

Product display

Company Features

· Liding Machine has innovative equipment to manufacture high-quality z purlin roll forming machine.

· To occupy a significant position, Liding Machine produces z purlin roll forming machine with the most advanced technology. Liding Machine applies the advanced technologies to produce z purlin roll forming machine.

· We are committed to maintaining the highest standards of quality and value in products and dependability in service. We always strive to better understand the wants, needs, and expectations of our customers and to constantly exceed those expectations.

Product Comparison

Compared with other products in the same category, z purlin roll forming machine has outstanding advantages which are mainly reflected in the following points.

Enterprise Advantages

Our employees are mainly composed of young people with outstanding professional skills and experienced experts. They have the good team spirit and ensure the efficient operation and our rapid development.

We have a professional service team to solve the technical problems in the process of purchasing and using for consumers.

With the tenet of 'customer first, reputation first', we insist on the policy of higher standards, higher quality and higher efficiency to truly manage with love and work with sincerity.

Since the establishment in Foshan Liding Technology Co.,ltd has greatly improved the core competitiveness and has achieved rapid development.

At present, Foshan Liding Technology Co.,ltd constructs a huge sales network in China while actively opening up the international market.