Top Track Roll Forming Machine for Factory

Product details of the track roll forming machine

Product Specification

Machinery Test Report: Provided

Product name: L Angle Roll Forming Machine

Control system: PLC(imported Brand)

Raw material: PPGI PPGL GI GL

Tile Type: Steel

Quick Overview

Liding Machine track roll forming machine has attracting designs with ingenuity. The quality of the product meets the latest industry standards. The product caters to different market needs, leading to a more promising market application prospect.

Product Introduction

Our track roll forming machine's outstanding quality is shown in the details.

Products Description

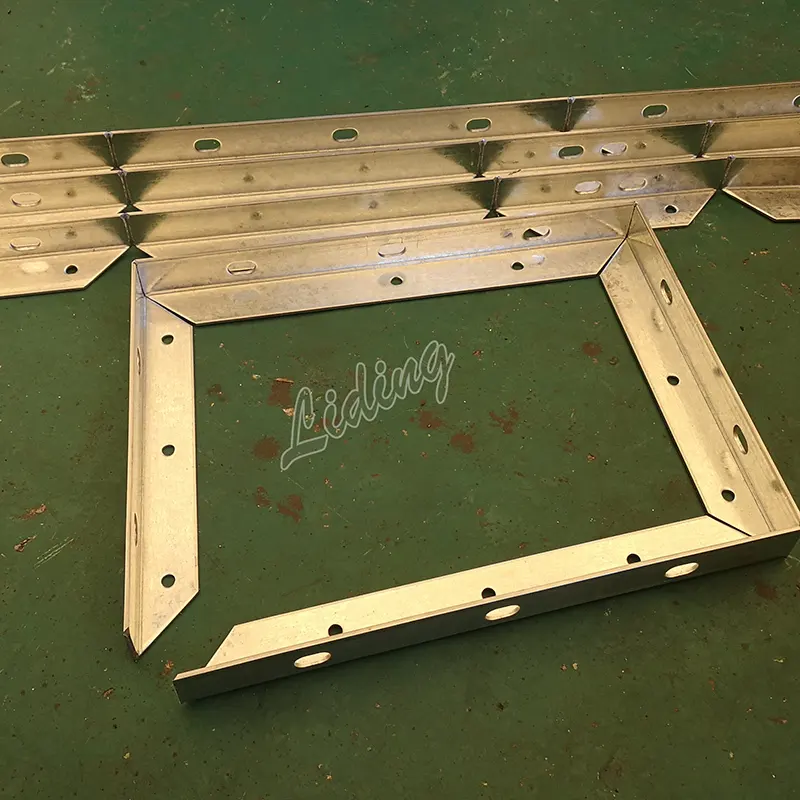

L Angle profile roll forming machine

Application

Angle steel can be used in blower frames or suspended metal and drywall ceiling or drywall partition systems.

Workflow

Decoiling - Roll Forming - (Servo) Punching 45° Angle - Punching Vertical Edge Hole - Punching Flat Edge Hole - Cutting (Outer Flange Cutting) - Finish

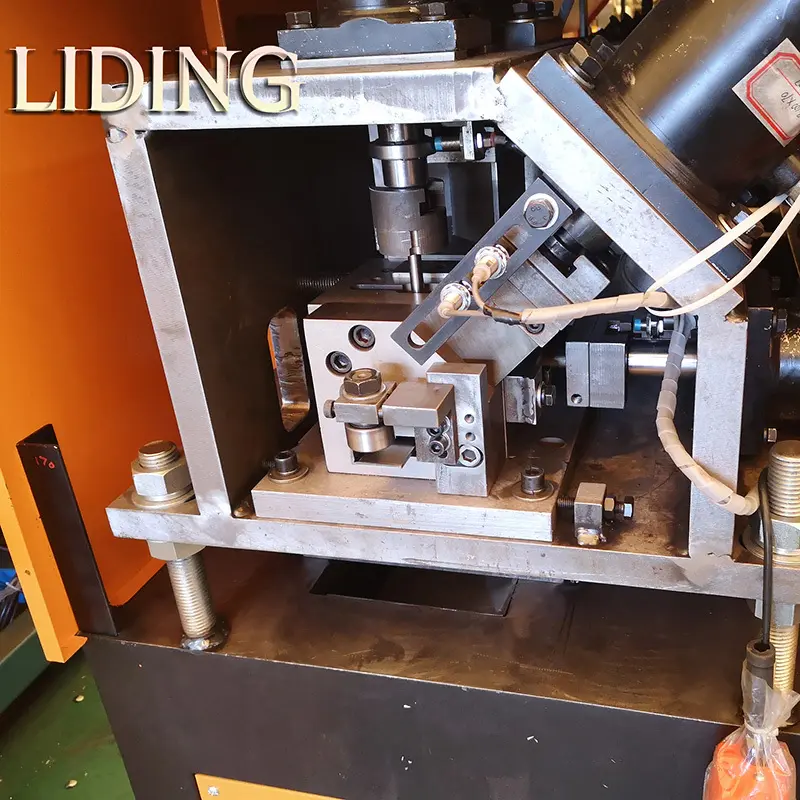

Composition of the machine

● Decoiler,1 set

● Forming machine,1 set

● Mold stations,4 set

● Angle-cutting mold,1 set

● Punching molds (combination of interchangeable cores),2 sets

● Cutting mold,1 set

● Hydraulic cutting system, 1 set

● PLC control 1 set

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 2.0mm

● Main motor power: 7.5kw

● Forming speed: 0-6m/min

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: gear transmission.

● Control system: PLC control

● Machine net weight: about 3tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 4m*0.8m*1.5m

● Forming roll material: Cr12MoV

Cutting off parts

● One set of hydraulic system, hydraulic motor 7.5KW, pressure 15Pa, four stations oil cylinder

● 3 sets of punching molds, 1 set of non-cutting molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping cutoff

Product display

Company Information

佛山市立鼎科技有限公司 (Foshan Liding Technology Co.,ltd) is a company located in fo shan. Our company is mainly engaged in the business of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. Foshan Liding Technology Co.,ltd has built a service system that meets the needs of consumers. It has won wide acclaim and support from customers. With years of experience in production, we guarantee our product quality so you can purchase them with confidence. Feel free to contact us!