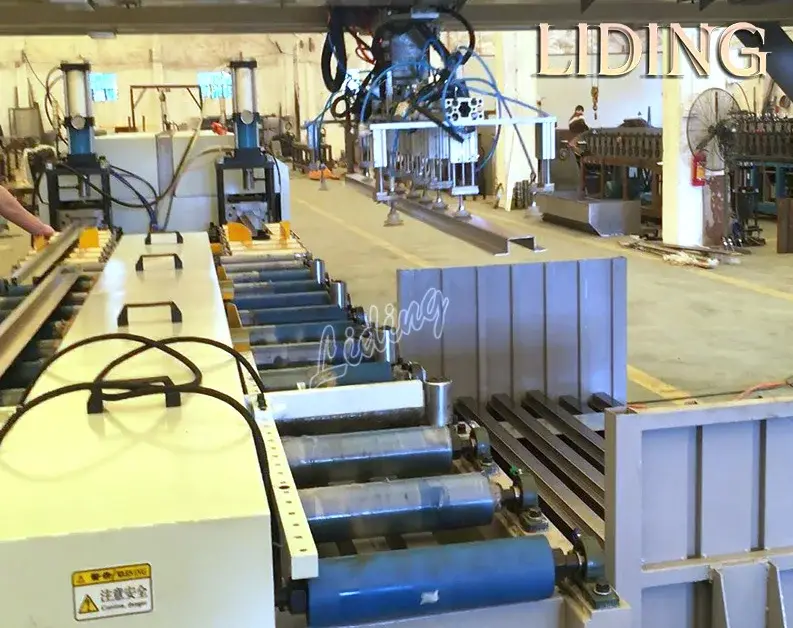

Steel Stud Roll Forming Machine Construction - for Factory - Liding Machine

Product details of the steel stud roll forming machine

Product Specification

Rolling thinckness: 0.4-3 mm

Product name: Track Roll Forming Machine

Key Selling Points: Automatic

Usage: Construction

Color: Client's Request

Quick Detail

We work with the best materials sourced from across the globe to give that extra lift to steel stud roll forming machine's quality. This product has good performance and is durable. It is much more important for Liding Machine to develop the sales network to be a leading steel stud roll forming machine supplier.

Product Introduction

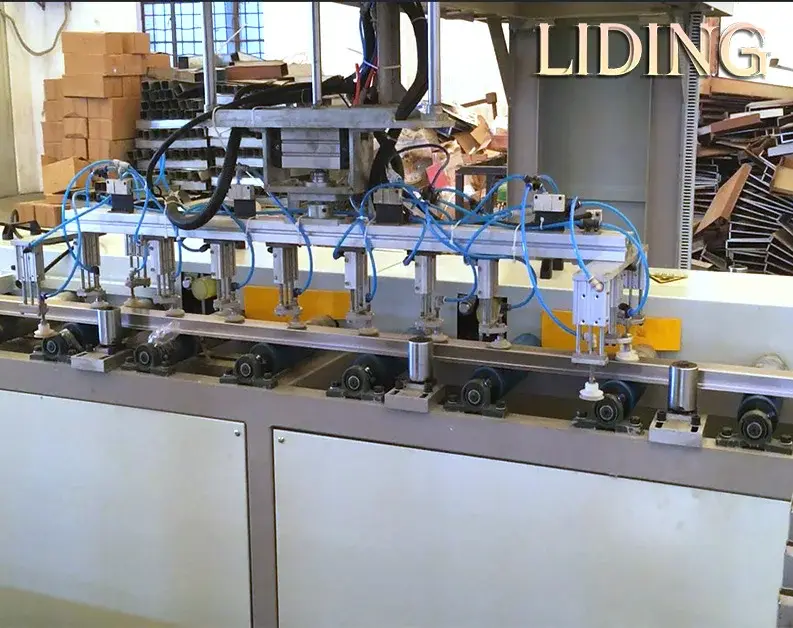

Foshan Liding Technology Co.,ltd pays great attention to details. And the details of steel stud roll forming machine are as follows.

Bottom reinforcement steel roll forming machine for elevators

Application

Other profiles

Specification

|

Serial number

|

composition

|

data

|

|

1

|

Manual Decoiler

|

Max. bearing load capacity 3000kg

|

|

2

|

Leveler

|

1 set

|

|

3

|

Sensor racks

|

2 set

|

|

4

|

Hydraulic punching unit

|

7 stations

|

|

5

|

Cold roll forming integral machine

|

1 set

|

|

6

|

Cutting device

|

1 Set

|

|

7

|

Hydraulic system

|

5.5KW

|

|

8

|

PLC automatic control equipment

|

Famous brand

|

Production process

Decoiling→ Roll Forming →Straightening → servo feeding → punching → roll forming → automatic cutting → unloading

|

Condition

|

New

|

|

Production Capacity

|

0-8m/min

|

|

Place of Origin

|

China,Guangdong

|

|

Brand Name

|

Liding

|

|

Voltage

|

380V 50Hz 3phases

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

Full Auto Omega Profile Channel roll forming machine

|

|

Roller material

|

cr12mov

|

|

Cutting blade material

|

CR12mov

|

|

Transmission

|

Gear

|

Main parameters

1 Main motor power 11KW

2 Transmission form Gear, chain

3 Rolling speed 0-8M/min

4 Maximum feeding width 250mm

5 Rolling mold material Cr12

6 Rolling mold heat treatment hardness HRC58-62

7 Mold surface roughness Ra0.8

8 Roller shaft material, diameter 40Cr, φ60

9 roller groups: 18+5

10 mold life ≥1.6 million meters

11 Residue recovery method Filter collection

12 Rolling mold replacement method Overall lifting, positioning pin fixed

Product display

Company Introduction

Liding Machine is a high-tech enterprise specializing in manufacturing steel stud roll forming machine. With a full commitment to improving customer services, we finally win many loyal customers and establish stable business cooperations with them. We take time to evaluate our services, make sure we respond to our customers timely about any problems related to the products. We think customer satisfaction as core part of our business. We work to exceed our client’s expectations while addressing their needs and providing professional services.

Look forward to working with you to create a better future.