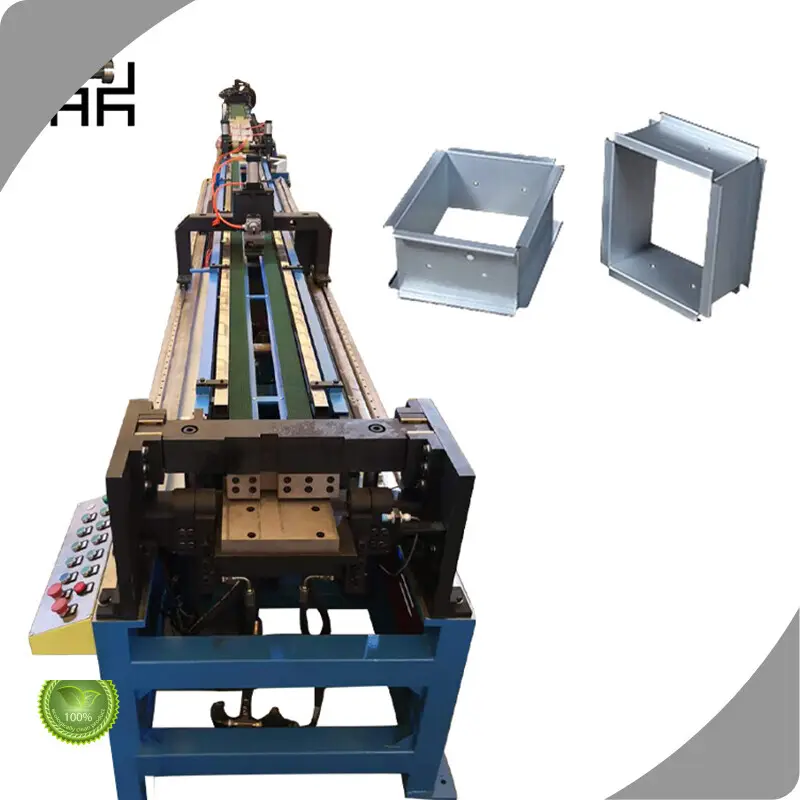

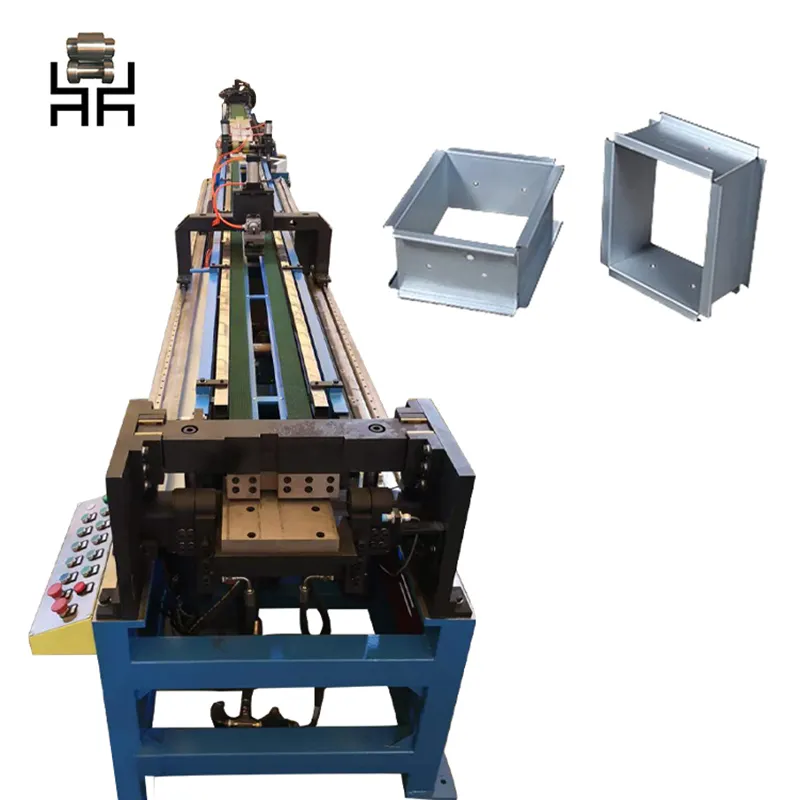

Roller Shutter Roll Forming Machine for Industrial Factory Price

Product details of the roller shutter roll forming machine

Product Description

Many of roller shutter roll forming machine come from world-class designers. All defects are removed from the products during the quality inspection process. With the advanced equipment, we concentrate on the quality of the products.

Fire Damper Frame Production Line Main Technical Parameters

|

Item |

Parameters |

|

Material |

Galvanized Sheet |

|

Material Thickness |

1.5 - 2.0 MM |

|

Width of Coil |

According to Customer's Requirement |

|

Weight of Coil |

≤ 3000 KGS |

|

Forming Speed |

1 – 15 M/Min, Adjustable |

|

Plate Length Error |

± 0.3 MM / 1000 MM |

|

Punching Hole Distance Error |

± 0.3 MM / 1000 MM |

|

Bending Error of Frame |

± 1.0 MM / 1000 MM |

|

Processing Flange |

TDF 35 MM |

|

Processing Mode |

Decoiling / Single Piece / Mouth Type / L Type / U Type |

|

Control Mode |

PLC Control |

|

Main Power Supply |

380 V, 50 HZ, 3 Phase |

|

Hydraulic System Pressure |

25 MPa, Working Pressure: 8 – 12 MPa |

|

External Dimensions of Line |

About 15000 * 1000 * 1200 MM (L*W*H) |

|

Total Power of Line |

About 26 KW |

|

Line Weight |

13800 KGS |

|

Production Efficiency |

350 - 400 Frames / 8 Hours |

Main features

Fire Damper Frame Roll Forming Machine Main Features:

1. Fast speed: save labor, can produce 300 – 400 frame 8 hours per shift by only 1-2 people.

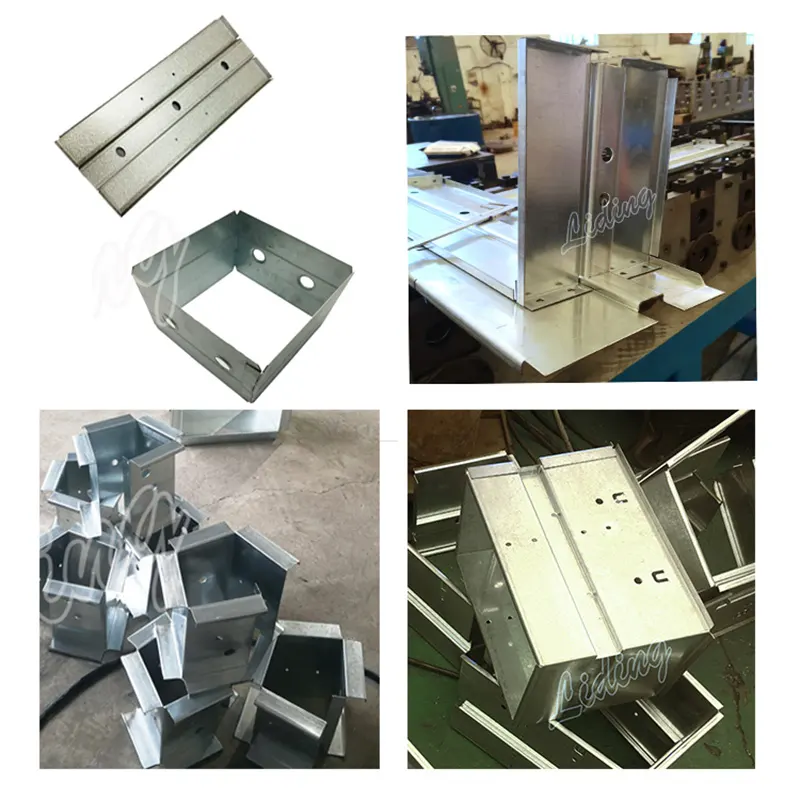

2. High precision: hole distance error ± 0.3 mm, length error ± 0.3 mm, diagonal error ± 1 mm.

3. Save material: the process design of cutting first and then forming ensures the whole process from debugging to production without waste.

4. High efficiency: continuous order mode, customers can input multiple order data at one time for continuous production.

5. Good forming effect: specially designed rollers to ensure less abrasion to zinc layer after galvanized sheet is formed.

6. Small bending R: specially designed bending tool as well as pre-punching indentation at the small edge, two processes to ensure that the bending angle is small.

7. Good stability: electrical components adopt international and domestic top brands, the main mechanical parts through careful design and fatigue test, to ensure the stable production of production line in high-intensity and high-load working environment.

8. Simple operation: the whole line is automatic, assembly line production, computer controlled and easy to learn.

9. Cover a small area: the total length of the line is only 15 meters.

Workflow

Automatic Fire Damper Frame Roll Forming Machine Production Process:

Decoiling → Material Guiding → Leveling → Edges Punching → Spindle Hole Punching (∅ 16 mm) → Temperature-Sensing Hole Punching (∅ 20 mm) → Hydraulic Cutting Off → Conveying → TDF Roll Forming → Hydraulic Automatic Bending → Manual Discharging.

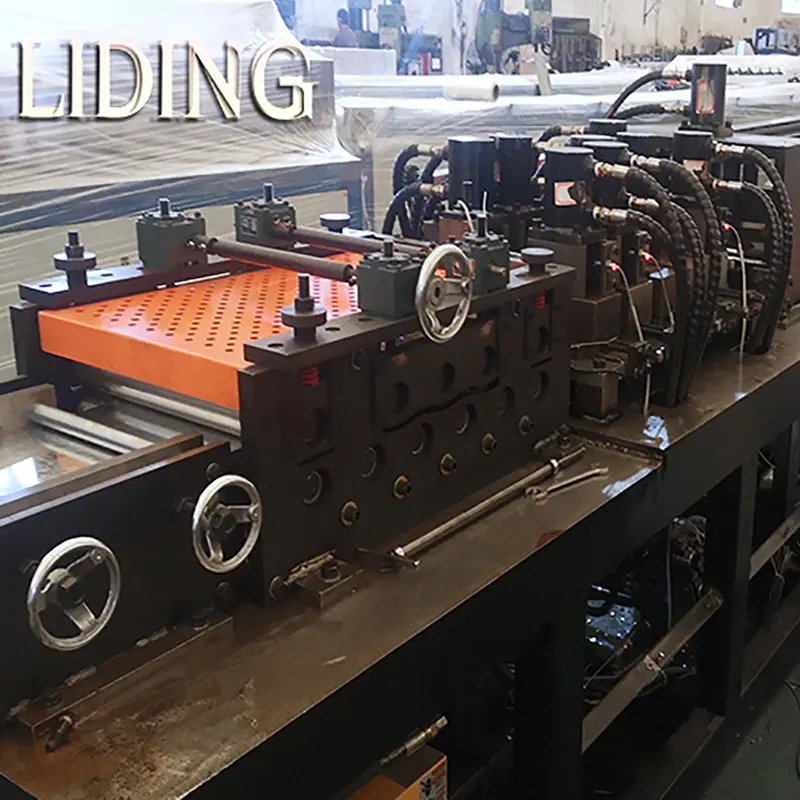

Damper outer frame roll forming Machine Compositions

|

Item |

Quantity |

|

Manual Decoiler |

1 Unit |

|

Leveling – Punching – Cutting Machine |

1 Unit |

|

Conveyor |

1 Unit |

|

TDF Roll Forming Machine |

1 Unit |

|

Hydraulic Bending System |

1 Set |

|

PLC Control System |

1 Set |

|

Hydraulic System |

2 Sets |

Product display

Company Feature

• Foshan Liding Technology Co.,ltd has opened up the international market based on diversified chain marketing. At present, the products share in the international market has rapidly increased.

• Since the establishment in Foshan Liding Technology Co.,ltd has been developing for years and has accumulated rich industry experience.

• Foshan Liding Technology Co.,ltd constantly takes talents in to enrich talent team. Now we have a professional and efficient production team, whose team members produce a large number of quality products depending on mature technology.

If you want to know more about Foshan Liding Technology Co.,ltd's Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines, please leave your contact information. We will send you the latest relevant product information and market information for your reference.