Roller Shutter Roll Forming Machine for Industrial Eries

Product details of the roller shutter roll forming machine

Quick Overview

Liding Machine roller shutter roll forming machine is completed with fine finishing in accordance with the quality standards of the industry. Its performance is guaranteed by well-selected materials. 佛山市立鼎科技有限公司 provides after-sale technical support for our roller shutter roll forming machine.

Product Introduction

Foshan Liding Technology Co.,ltd's roller shutter roll forming machine is produced in strict accordance with standards. We make ensure that the products have more advantages over similar products in the following aspects.

Main features

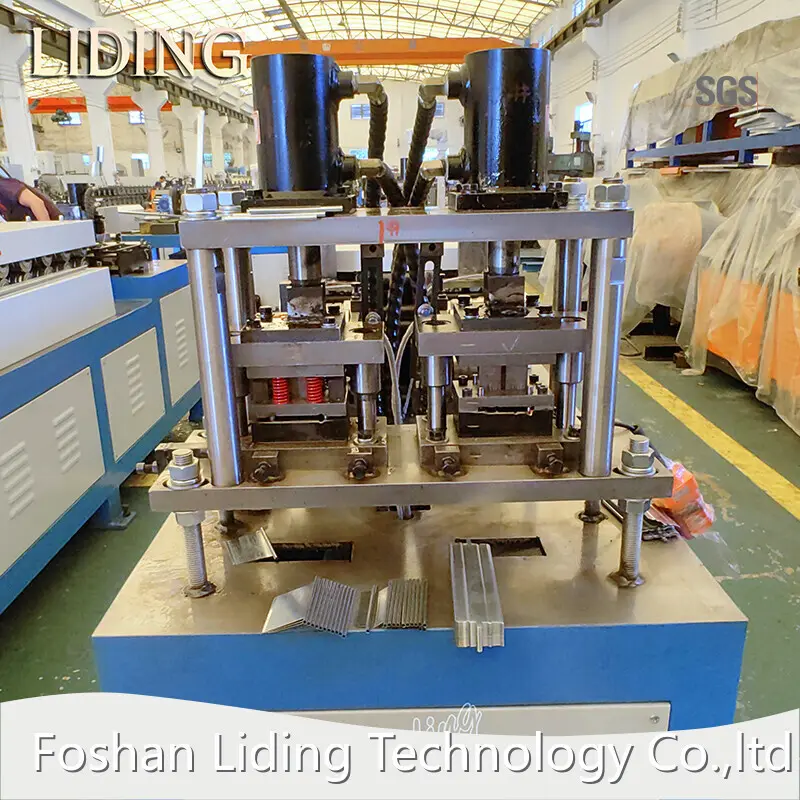

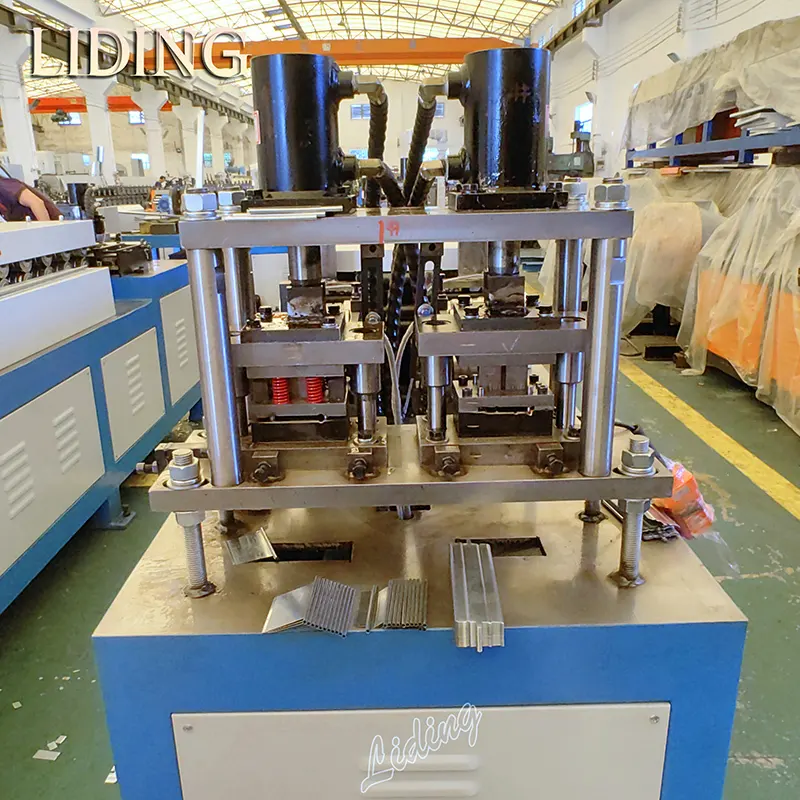

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:Blade1.0mm;Blade type 1\2\3 0.5mm

● The forming rolls of the two products are installed side by side on the same frame to produce two specifications of profiles respectively.

● Blade type 1\2\3 is notched before forming.

● The frame is welded with 100*80 pipe.

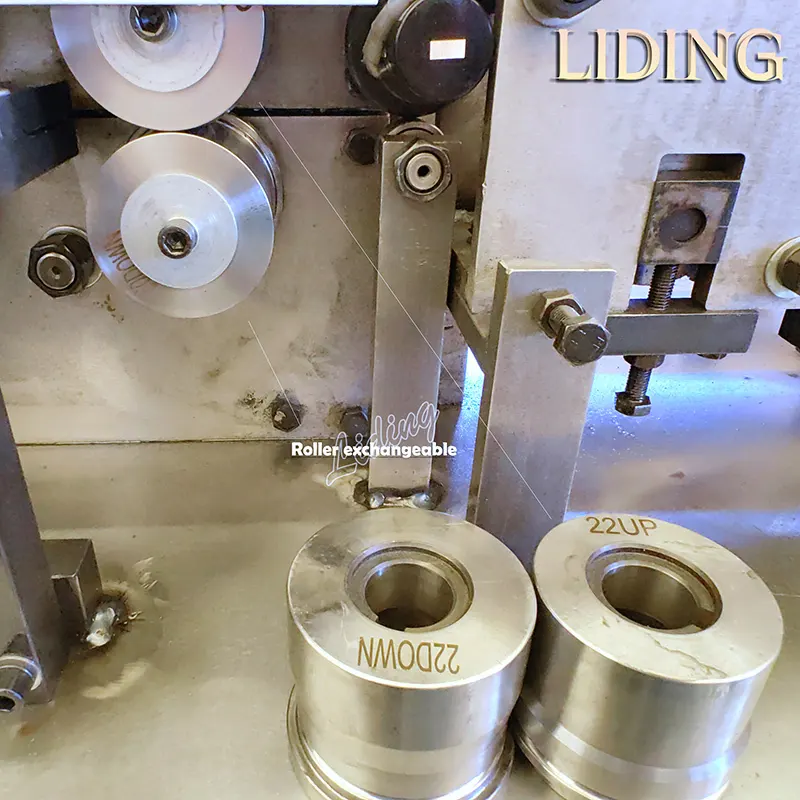

● Rolling roller 10 sets

● Rolling roller material GCr15 steel

● Rolling roller heat treatment HRC55°~57°.

● Rolling wheel bearing diameter 42mm, material 45# steel.

● Rolling roller bearing specification 6207

● Plywood thickness 25㎜

● Transmission method Chain and gear wheel

● Motor power 3 kW, K77

● Forming speed 6 m/min

Composition of the machine

● Manual Decoiler ,1 set

● Forming main machines (Internal and external ),1 set

● Hydraulic system Mold,1 set

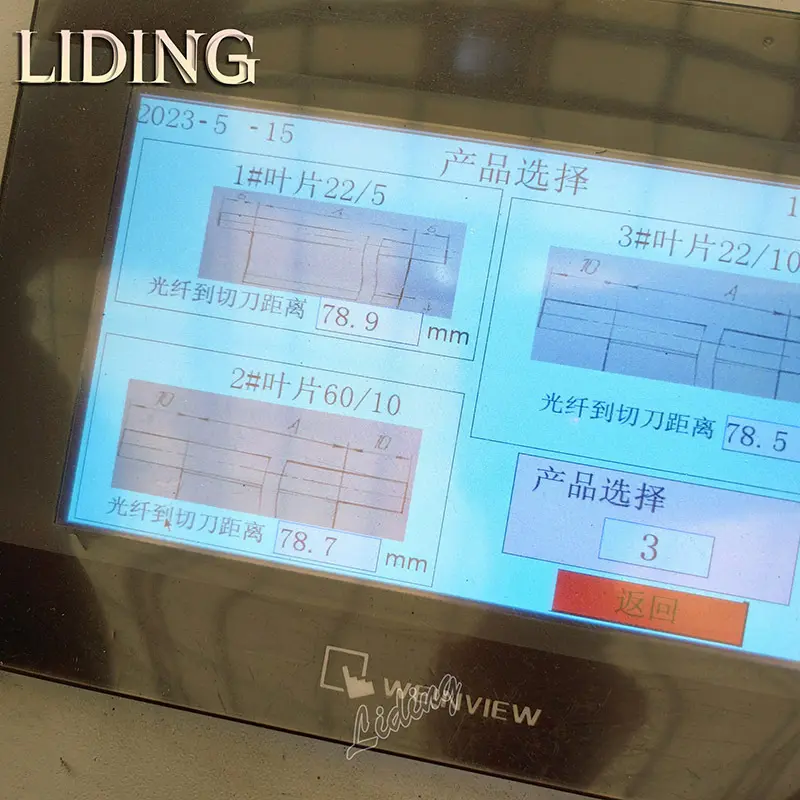

● Electric control device (touch screen, inverter, PLC, etc.)

Cutting off parts

● With a set of hydraulic system device

● With Blade cut off mold 1 set, Blade type 1\2\3 cut off mold, 2 sets (replacement)

● Motor power 2.2kw

● Adopt cylinder control cutting method

● Cutting off by stopping the machine

Run out table

● Flat length 1 meters

● Flat table structure using square tube angle iron composition.

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Adopt Panasonic PLC, human-machine interface control and domestic inverter for speed regulation.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting length of the way

● Electronic control box adopts fully sealed ventilation and cooling device.

● Control box using fully sealed ventilation cooling device

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

Workflow

Decoiling -Punching- Cold Roll Forming - Cutting - Unloading - Finishing

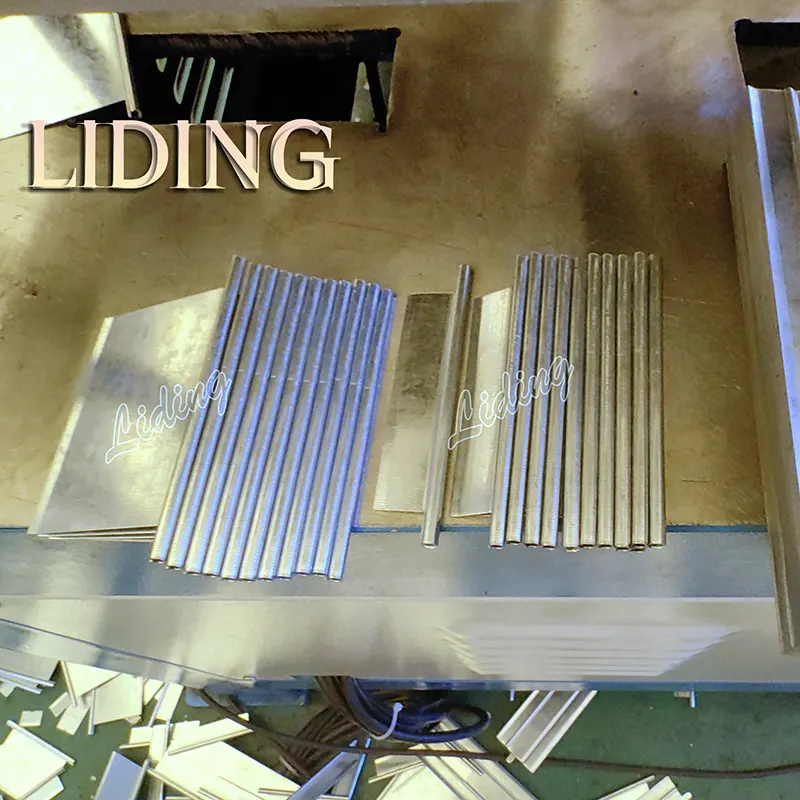

Product display

Company Advantages

佛山市立鼎科技有限公司 (Foshan Liding Technology Co.,ltd), located in fo shan, is production company. And the main product is Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. In the following days, Foshan Liding Technology Co.,ltd will always abide by the business philosophy of 'based on integrity, win by quality'. In addition, we keep promoting our enterprise spirit of 'exploring and progressing, changing through innovations'. We are committed to becoming a leader in the industry with international influence, therefore, we make use of our own resource advantages to improve brand building and core competitiveness. Foshan Liding Technology Co.,ltd's high-quality and highly educated elite team serves as the motivation for Foshan Liding Technology Co.,ltd's healthy and sustainable development. We understand the actual situation of the market, and then combine the needs of customers. In this way, we develop the most suitable solutions for customers and effectively meet their needs.

We provide you with high-quality products and look forward to your inquiry.