Rack Roll Forming Machine New - for Factory - Liding Machine

Product details of the rack roll forming machine

Product Specification

Rolling thinckness: 1.5mm

Condition: New

Roller stations: 38 Roller Stations

Raw material: Galvanized Coil

Cutting blade material: Cr 12 High Grade Steel

Quick Detail

During the design of Liding Machine rack roll forming machine, the design team devotes themselves in research and overcomes some of the product defects that can not be disposed of in the current market. A large amount of time and effort are taken for its performance. And the quality controls are implemented at every level of the entire supply chain to ensure the top quality of this product. Foshan Liding Technology Co.,ltd's rack roll forming machine is of excellent quality and is widely used in the industry. The potential application value of the product is worth discovering.

Product Introduction

With a focus on every detail of rack roll forming machine, we strive to create high-quality products.

Products Description

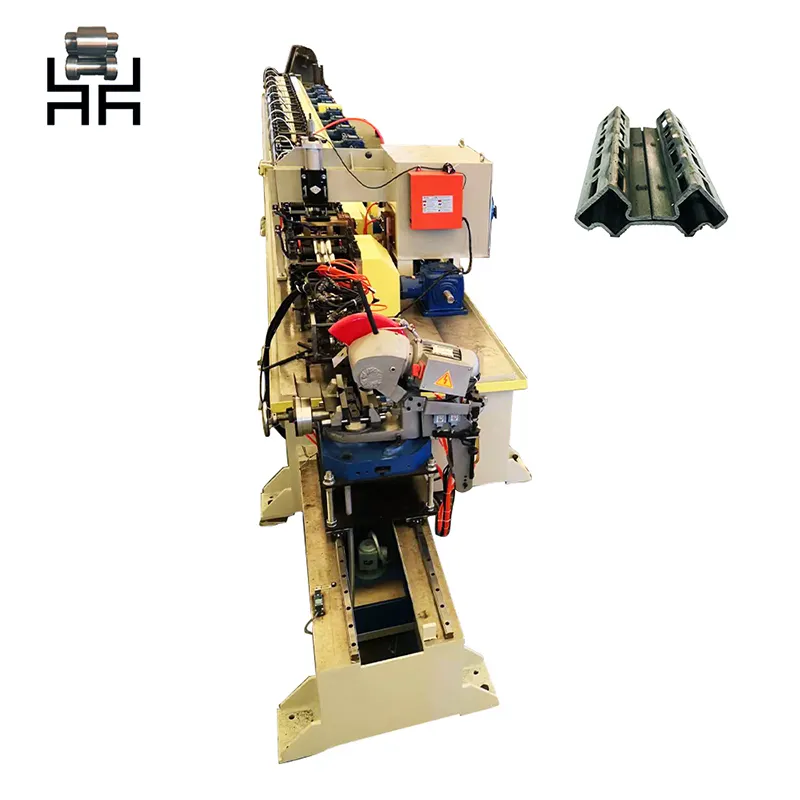

Electrical Cabinet Rack Roll Forming Machine

This line consists of decoiler, leveler and feeding device, non-stop punching device, roll forming main machine,length measure cutting device,run out table,PLC electric system.

Professional Service

1. Customized Machines

2. Professional Designed

3. Quality Assurance Team

4. Technical Support

5. Excellent Quality Production Guaranteed

Product Specifications

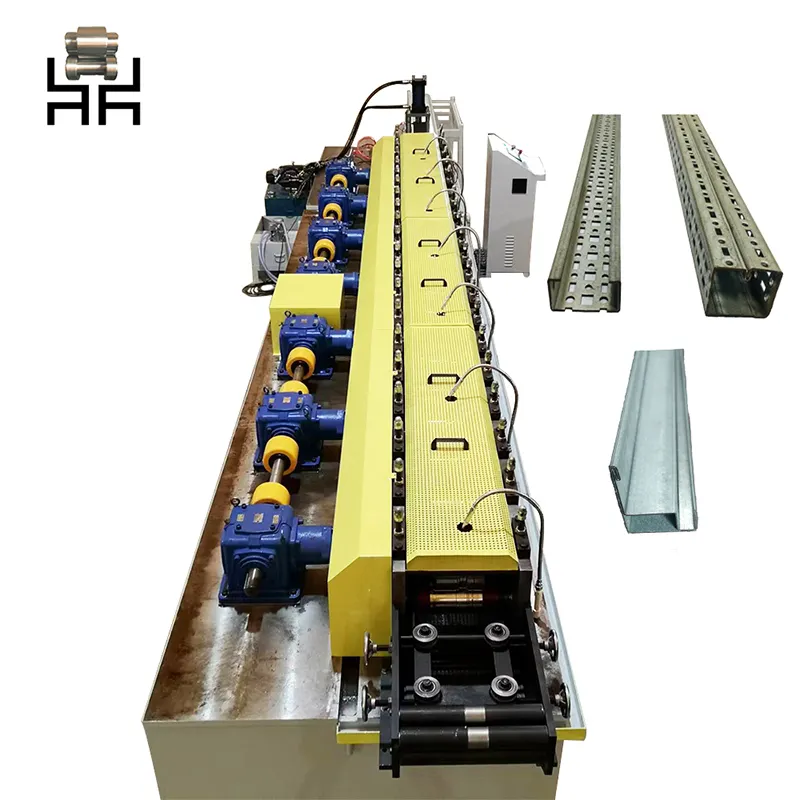

Electrical Cabinet Rack Roll Forming Machine details

● Feeding material: aluzinc/galvanized steel or as customer request

● Machine table: 100*80 steel pipe welding

● Number of molding groups: 38 groups+5 groups straightening

● Side plate thickness:25mm

● Roller material: GCr15 steel

● Control systerm: PLC control system with touch screen

● Roller driven type: gear transmission

● Power supply:380v,3phase,50hz

|

No

|

Item

|

Date

|

|

1

|

Decoiler

|

1 set

|

|

2

|

Leveler and feeding device

|

1 set

|

|

3

|

Punching device

|

1 set

|

|

4

|

Roll Forming Main Machine

|

1 set

|

|

5

|

Roll welding machine

|

1 Set

|

|

6

|

Circular saw cutting device

|

1 set

|

|

7

|

run out table

|

1 set

|

|

8

|

PLC controller system

|

PLC control system with touch screen

|

Producing process

Electric decoiler→Servo feed→Punching→Material reversal→Cold roll forming→Rolling welding→Circular saw cutting→Cylinder pushes the

finished product to the collection platform

Gearbox transmission

Product display

Company Information

Located in fo shan, 佛山市立鼎科技有限公司 is a professional enterprise in the industry. The main products include Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. With the main focus on customers, Foshan Liding Technology Co.,ltd takes a proactive approach to seek development. We always put customers and services first, which is the reflection of the core value. Our commitment is to provide customers with efficient and high-quality services. Our company has a first-class independent R&D team and a strong infrastructure for scientific research. In order to integrate scientific research and production, our team members continue to make improvement in system, technology, management and innovation. It is good for accelerating the transformation and industrialization of scientific and technological achievements. We have a professional team and can provide customers with the most appropriate solutions to help customers achieve their goals quickly and effectively.

If interested in our products, you are welcomed to contact customer service staff for consultation!