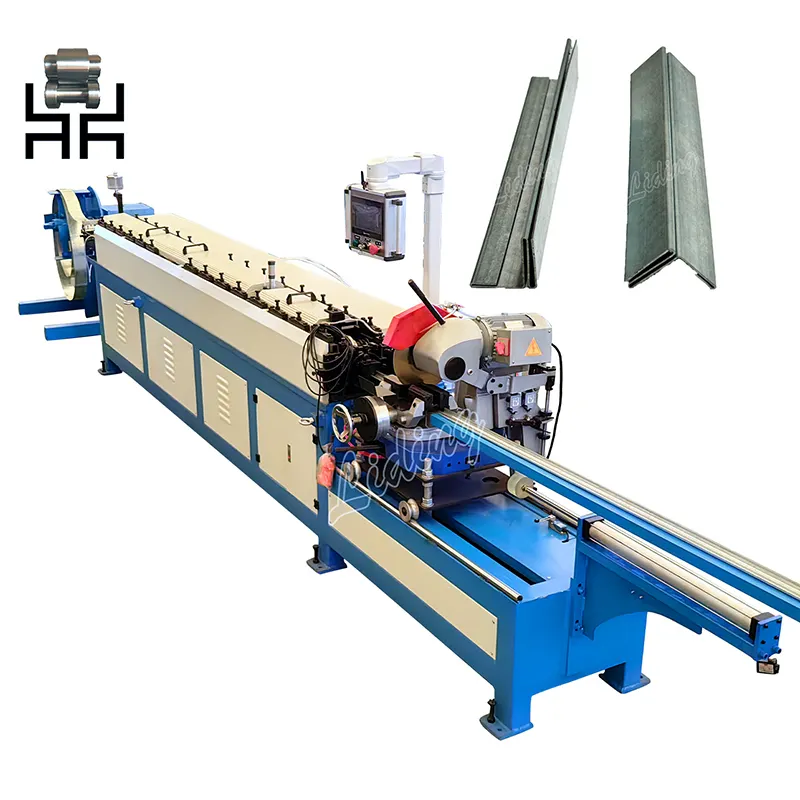

Professionalduct Machines for Factory

Product details of the duct machines

Product Introduction

Standard manufacturing: the production of Liding Machine duct machines is based on the advanced technology developed by ourselves autonomously and the complete management system and standards. We adhere to strict industry quality standards, fully ensure that our products meet international standards. duct machines has attracted many customers with its high quality assurance.

Profile

Main features

Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 1000kg

● Quantity: One.

● Manual Expansion

● Powerless drive, with brake

Forming machine

● Applicable materials: Galvanized sheet metal

● Material thickness: 0.7-1.2mm

● Main motor power: 3.7kw

● Molding speed: 6-8m/min

● Number of molding groups: 16 groups

● Shaft diameter and material: ¢ 42mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 2.5 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 6m*0.7m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

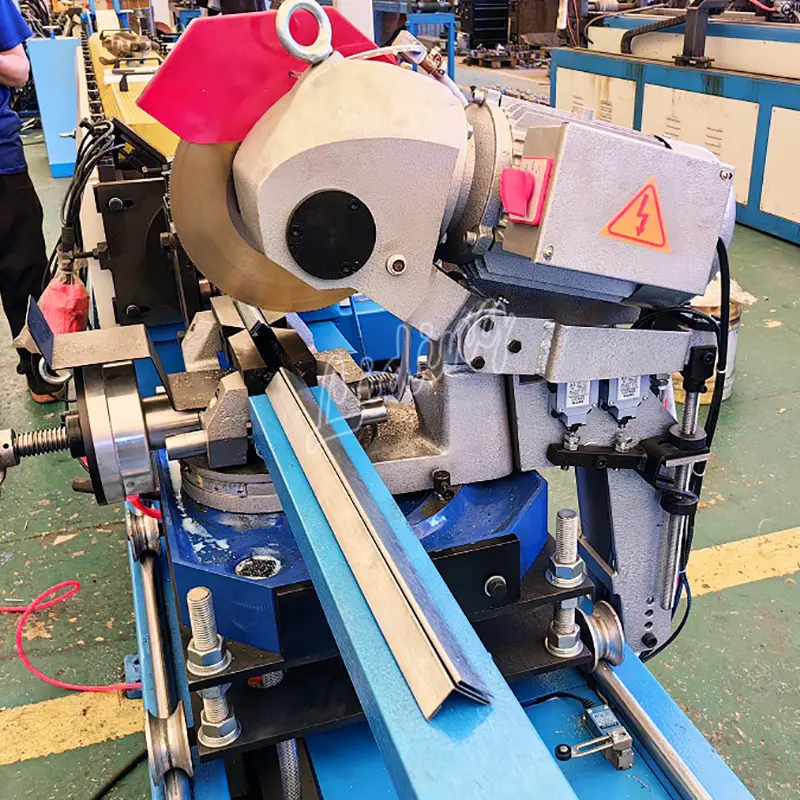

Mechanical circular saw cutting off part

● Motor power 2.2 kW

● Mechanical circular saw with saw blade

● Mold material: CR12MOV

● Processing hardness HRC60 ° -62 °

● The encoder detects the online shutdown cut-off

Run out table

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● The length is counted by internal encoder.

● The electric control box adopts fully sealed ventilation and cooling device.

● The power supply of control system adopts overload protection.

● Adopting shutdown cut-off method.

Workflow

Decoiling - Cold Roll Forming - Cutting - Unloading - Finishing

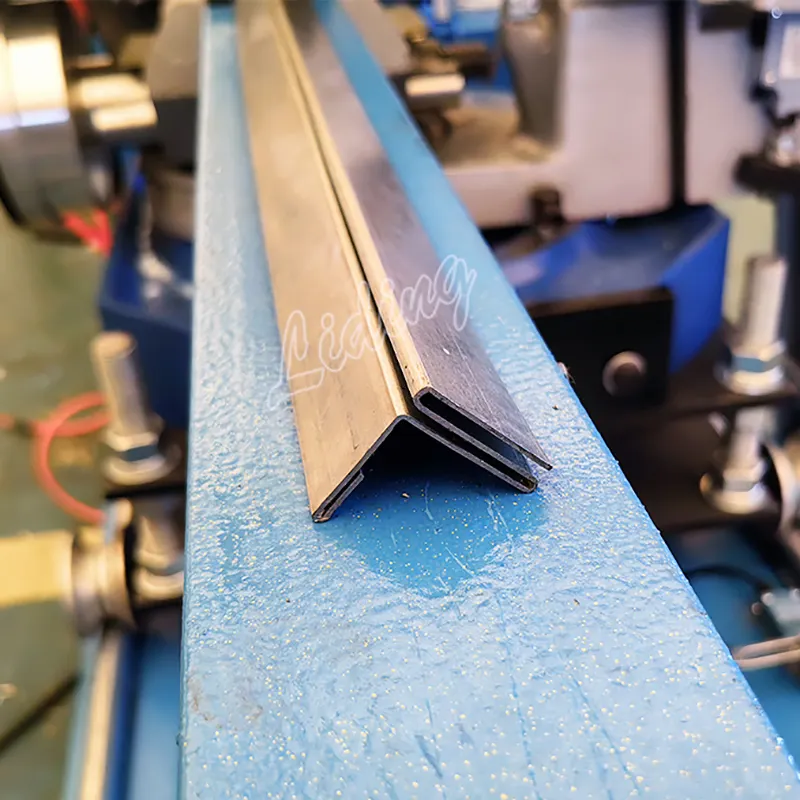

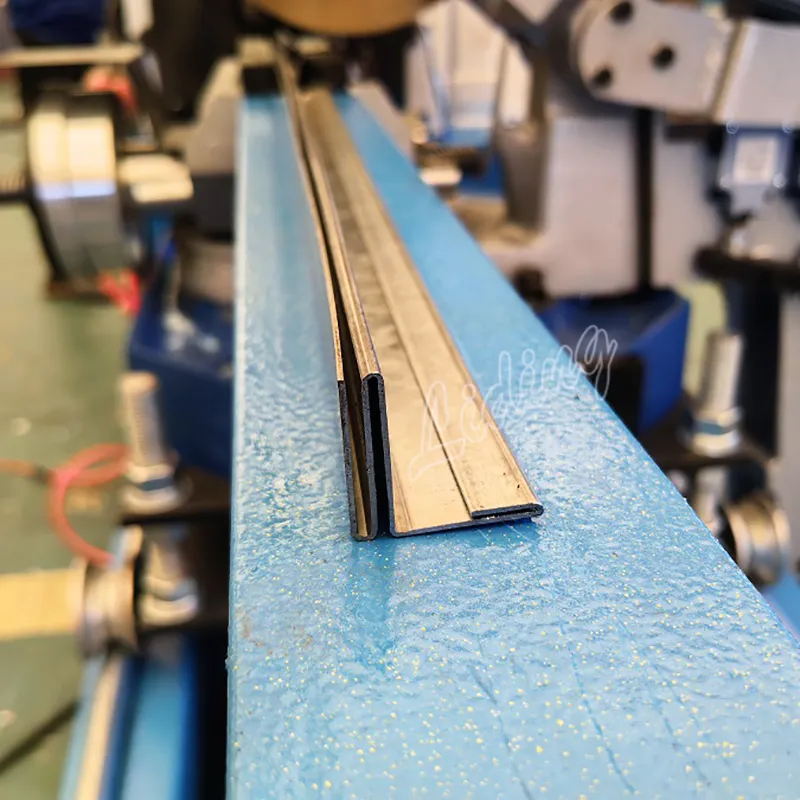

Product display

Company Feature

• Foshan Liding Technology Co.,ltd actively develops export business. Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines are mainly exported to Europe, America, Africa, South Asia, Southeast Asia, and other regions.

• Built in Foshan Liding Technology Co.,ltd has accumulated rich production and management experience after years of development.

• A number of highly skilled and experienced engineers lay a solid foundation for the development of Foshan Liding Technology Co.,ltd.

• provides customers with a full range of services to meet the individual needs of different customers.

If you have any questions about Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines displayed on the website, please feel free to contact Foshan Liding Technology Co.,ltd for consultation.