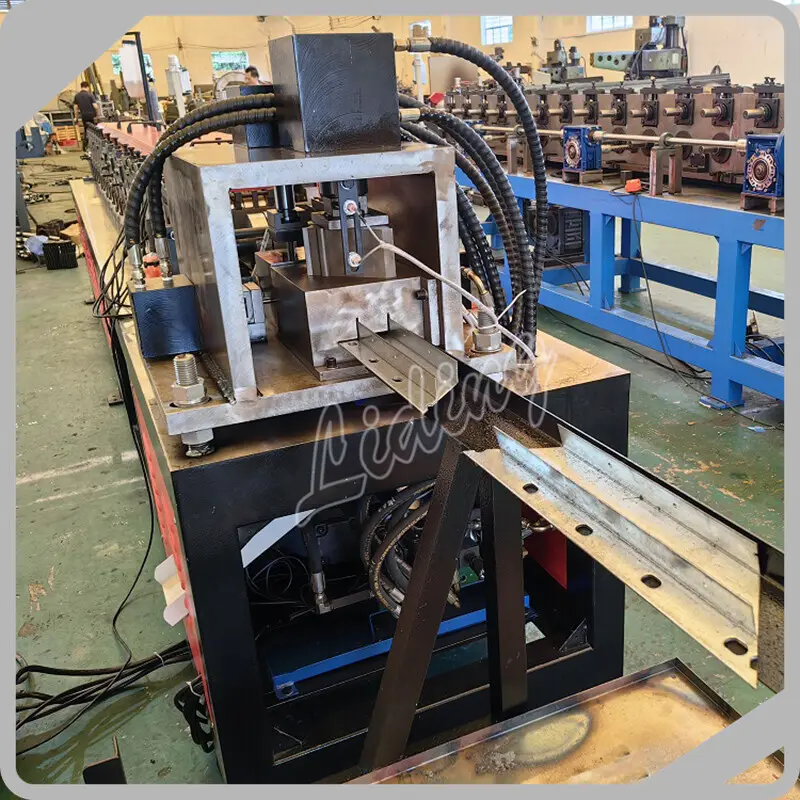

Professionalcold Forming Machine for Factory

Product details of the cold forming machine

Product Introduction

All raw materials of Liding Machine cold forming machine undergo rigorous quality checks. cold forming machine is well sold throughout the country and is well received by users. 佛山市立鼎科技有限公司 has established a strong brand competitive advantage.

Profile

Workflow

Decoiling - Cold Roll Forming - Cutting - Finishing

Composition of the machine

● Decoiler,1 ton

● Forming machine,18 groups

● Hydraulic cut-off mold,3 set

● Run out table,1 set

● PLC control cabinet,1 set

Basic Configuration

I. Electric Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 1000kg

● Quantity: One.

● Manual Expansion

● No power transmission,with brakes.

II. Forming machine(5)

● Applicable materials:Galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 11kw

● Molding speed: 1-3m/min

● Number of molding groups: 18 groups+5 groups straightening

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 3 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

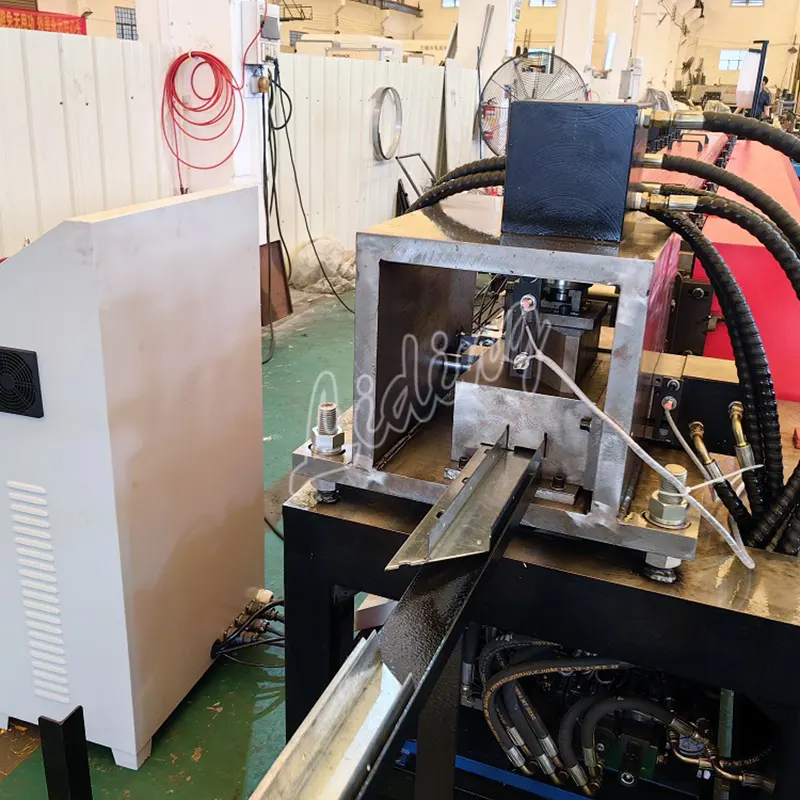

V. Cutting off parts(1)

● With a set of hydraulic system device

● Hydraulic motor 7.5KW, one station oil cylinder

● With 1 set of flange hole molds, 2 sets of spigot hole molds, 1 set of 45-degree cut-off molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping and cutting.

VI. Run out table

● Flat length 1 meters

● Flat table structure using square tube angle iron composition.

Basic Configuration

VII. PLC computer control cabinet(3)

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting method

● Electronic control box adopts fully sealed ventilation cooling device.

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

Product display

Company Advantage

• Foshan Liding Technology Co.,ltd is committed to providing quality and efficient services for customers.

• Foshan Liding Technology Co.,ltd has a group of experienced personnel with the professional and dedicated spirit.

• Foshan Liding Technology Co.,ltd's Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines are supplied throughout the country. Some products are exported to some countries and regions in Europe, America, Africa and Southeast Asia.

If you want to know Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines's quotation, please leave your contact information. Foshan Liding Technology Co.,ltd will send it to you for your reference.