Professional Cold Rolled Steel Machine 5000*800*1200mm Liding Machine Company

Product details of the cold rolled steel machine

Product Specification

Shaft material: 45# Steel Forging Treatment

Warranty of core components: 1 Year

Marketing Type: Ordinary Product

Dimension(L*W*H): 5000*800*1200mm

Showroom Location: None

Product Description

Liding Machine cold rolled steel machine is manufactured utilizing advanced technology and first-class equipment. The functional defects of this product have been overcome by the professional team. The offered product is highly demanded among customers due to its outstanding features.

Products Description

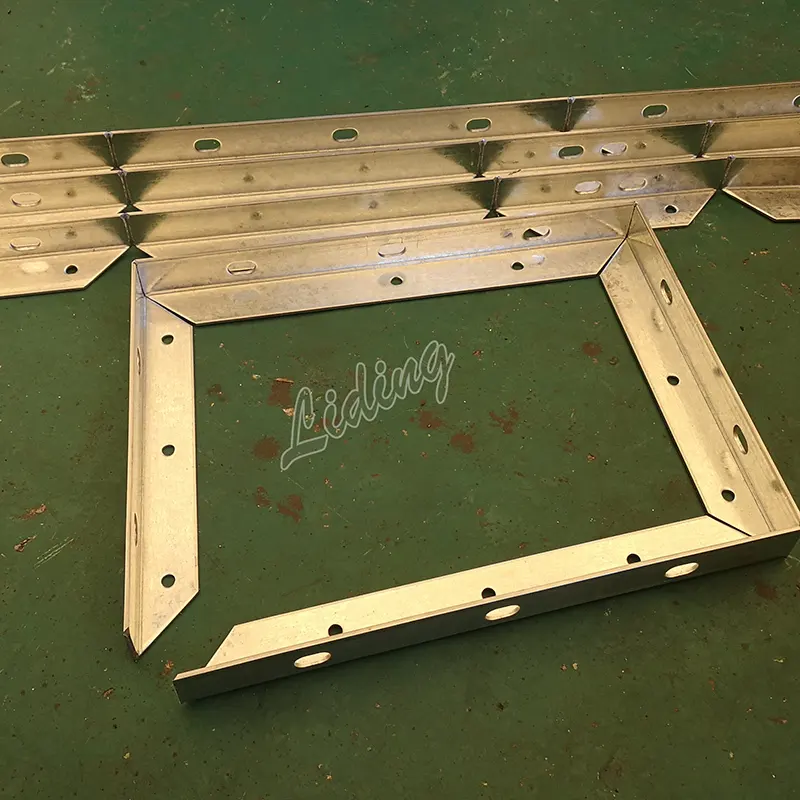

L Angle profile roll forming machine

Application

Angle steel can be used in blower frames or suspended metal and drywall ceiling or drywall partition systems.

Workflow

Decoiling - Roll Forming - (Servo) Punching 45° Angle - Punching Vertical Edge Hole - Punching Flat Edge Hole - Cutting (Outer Flange Cutting) - Finish

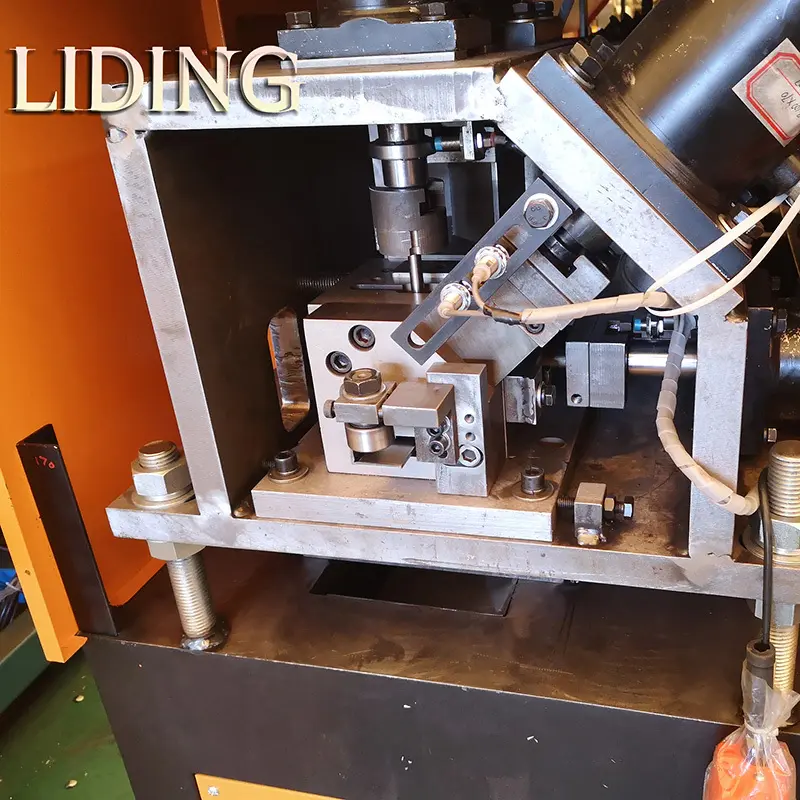

Composition of the machine

● Decoiler,1 set

● Forming machine,1 set

● Mold stations,4 set

● Angle-cutting mold,1 set

● Punching molds (combination of interchangeable cores),2 sets

● Cutting mold,1 set

● Hydraulic cutting system, 1 set

● PLC control 1 set

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 2.0mm

● Main motor power: 7.5kw

● Forming speed: 0-6m/min

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: gear transmission.

● Control system: PLC control

● Machine net weight: about 3tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 4m*0.8m*1.5m

● Forming roll material: Cr12MoV

Cutting off parts

● One set of hydraulic system, hydraulic motor 7.5KW, pressure 15Pa, four stations oil cylinder

● 3 sets of punching molds, 1 set of non-cutting molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping cutoff

Product display

Company Feature

• Since the beginning in Foshan Liding Technology Co.,ltd has been focusing on the business of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. After years of development, we gain remarkable results in the management.

• Our company has a group of teams experienced for research and development and production management. They can independently complete all aspects from production, quality control to export. And our products can meet the requirements of customers and the market for product quality.

• Our company implements strict management on after-sales service of products. And it effectively improves the quality of after-sales service and enables every customer to enjoy the service right.

• The natural resources around Foshan Liding Technology Co.,ltd are abundant. The geographical condition is excellent which brings developed information and traffic convenience.

Contact Foshan Liding Technology Co.,ltd and enjoy the free time-limited discount!