Oem & Odmelbow Cold Forming Machine for Industrial New Product 2020 Pressure Vessel

Product Description

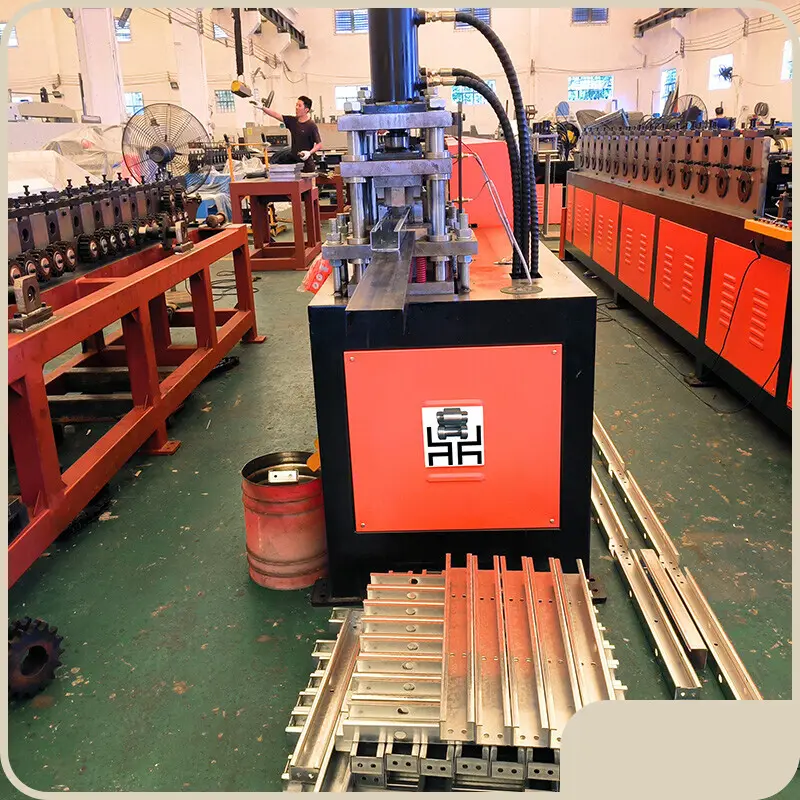

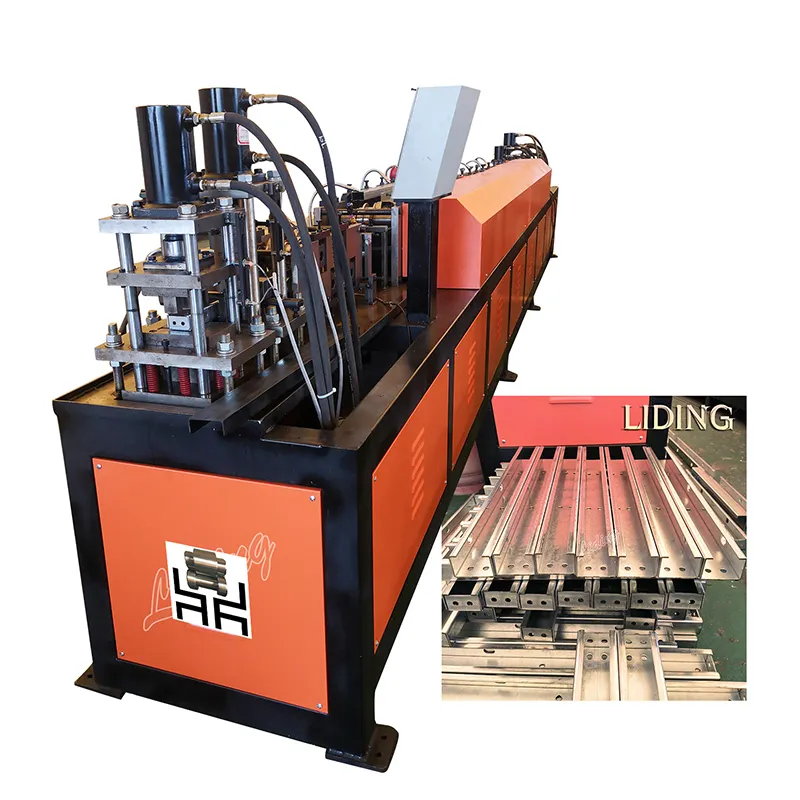

C Profile Air Blower Base roll forming machine

2-in-1 C profile machine: 2 profile production available as an option

Production process

Powerless uncoiling - servo flat feed -hydraulic punching round hole & punching square hole mold (4 sets), cut off the tail material - cold roll forming - cut off - cut off folding - finish

|

Serial number

|

composition

|

data

|

|

1

|

Manual Decoiler

|

Max. bearing load capacity 2000kg

|

|

2

|

Servo leveling feeder

|

Feeding speed: 15 meters / min

|

|

3

|

Hydraulic punching machine

|

25-ton cylinder hydraulic station with a power of 7.5kw

|

|

4

|

Punching mold, 4 sets

|

Mold material CR12MOV

|

|

5

|

Tail material cutting mold

|

1 set

|

|

6

|

Cold roll forming machine

|

15 stations

|

|

7

|

Forming and cutting mold

|

material Cr12MOV

|

|

8

|

Cutting and folding mold

|

material Cr12MOV

|

|

9

|

Hydraulic system

|

7.2KW

|

|

10

|

PLC automatic control equipment

|

Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

|

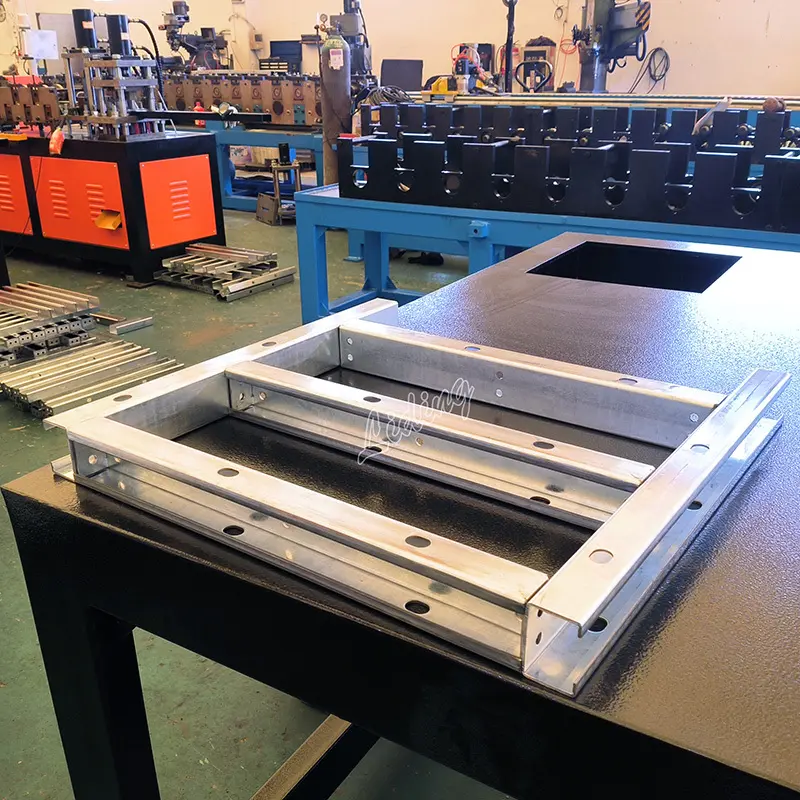

Application

Machine-produced profiles for blower bases.

Specification

|

Condition

|

New

|

|

Production Capacity

|

0-8m/min

|

|

Place of Origin

|

China,Guangdong

|

|

Brand Name

|

Liding

|

|

Voltage

|

380V 50Hz 3phases

|

|

Dimension(L*W*H)

|

6000*800*1200mm

|

|

Weight

|

4000kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Rolling thinckness

|

2.0-2.5mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

C Profile Air Blower Base roll forming machine

|

|

Roller material

|

cr12mov

|

|

Cutting blade material

|

CR12mov

|

|

Servo motor

|

7.5kw+7.5kw

|

|

Transmission

|

Chain & gear transmission.

|

Basic Configuration

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 300mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

● The main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counts the length of the way

● Electronic control box adopts fully sealed ventilation cooling device.

● Adopt shutdown cut-off mode

NC numerical control Leveling & feeding machine

● Material width: 200mm

● Maximum thickness of material: 2.5mm

● Flat feed shaft 11 rollers

● Servo motor: AC1.5KW

● Feeding speed: 15 meters / min

Punching mold,4set

● Width of material: unspecified

● SMaterial thickness 2.0-2.5mm

● Mold material CR12MOV

● Hydraulic system: a set of 25-ton cylinder hydraulic station with a power of 7.5kw;

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 0-2.5mm

● Main motor power: 5kw

● Molding speed: 0-8m/min

● Number of molding groups: 15 groups

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

Cutting off parts

● Adopt online fiber optic detection to cut off the machine.

● Cut off mold 1 set, material Cr12MOV

● Cutting and forming mold 1 set

Product display

Company Advantages

· Liding Machine elbow cold forming machine is manufactured by a sophisticated production process.

· The product is of reliable quality because it is manufactured and tested in accordance with widely recognized quality standards.

· Our excellent team saves valuable time & resource for customers whiling producing elbow cold forming machine.

Company Features

· As a reputable manufacturer of elbow cold forming machine, 佛山市立鼎科技有限公司, in virtue of strong R&D and manufacturing abilities, has become a notable expert in this field.

· We operate our business by utilizing up-to-date production facilities. These facilities are imported from the United States, Japan, Germany, etc. With their advanced technologies, our production plan can be ensured.

· 佛山市立鼎科技有限公司 aims to quickly and efficiently drive the implementation of its innovation. Inquire now!

Application of the Product

The elbow cold forming machine produced by our company is widely used in various industries and fields.

Foshan Liding Technology Co.,ltd insists on providing customers with reasonable solutions according to their actual needs.