Oem & Odm Double Layer Roll Forming Machine Liding Machine Manufacture

Technical Parameters

|

Machine Name |

Explain |

Quantity |

Motor(KW) |

|

|

De-coiler |

Manual Expanding |

1 Set |

Manual |

|

|

Leveling System |

9 Rollers |

1 Set |

2.2 |

|

|

Punching Sytem |

Servo Feeding |

|

1 Set |

1.3 |

|

Punching-1 |

The Middle of punching flanging part |

1 Set |

5.5 |

|

|

Punching-2 |

Punching head of the flanging part |

1 Set |

||

|

Main Roll Forming Machine |

|

1 Set |

5.5 |

|

|

Hydraulic Cutting System |

|

1 Set |

4 |

|

TECHNICAL SPECIFICATION

Voltage: 380V,50Hz,3phase。

Raw material width: around 196 mm

Material thickness:0.8mm to 1.2mm

Material: Galvanized and stainless sheet

Production speed: around 6M/min

Production length: ≥3000mm

Equipment total installed capacity: Around 20KW

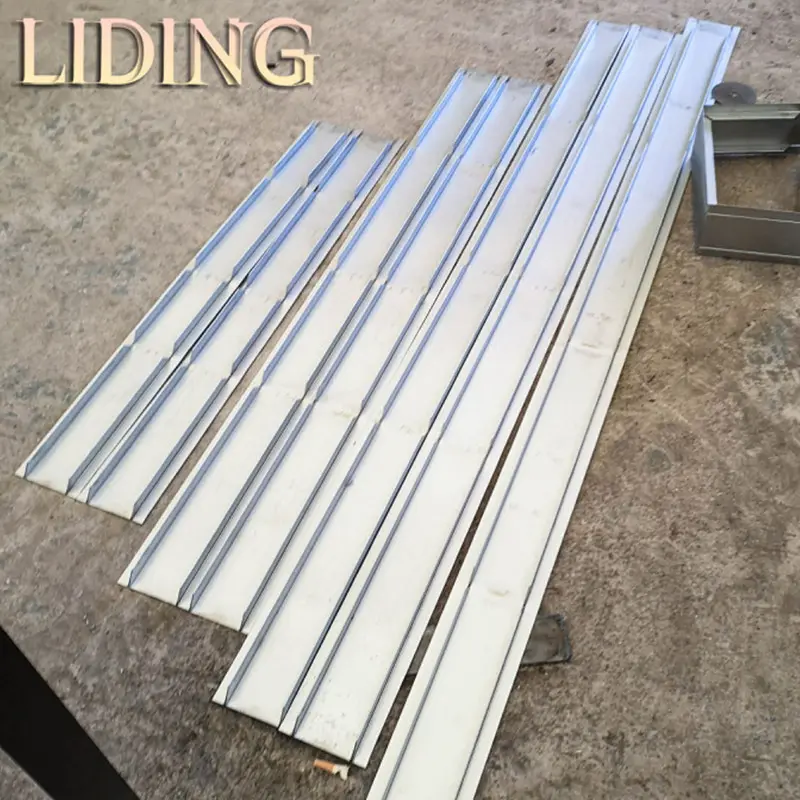

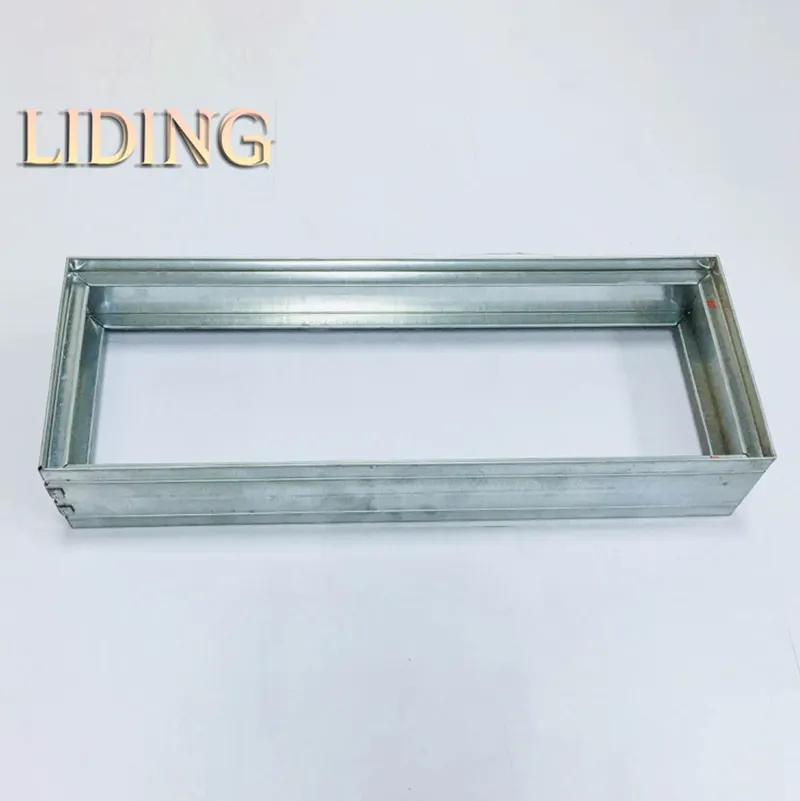

Product display

Company Advantages

· From the materials to designs, Liding Machine double layer roll forming machine is totally guaranteed by our professional expertise.

· The stringent norms of quality and cutting-edge technologies ensure the quality of this product.

· Most costumers consider the product has huge market potential and worth of trust.

Company Features

· 佛山市立鼎科技有限公司 is a favorable choice for manufacturing double layer roll forming machine. We provide competitive pricing, service flexibility, reliable quality, and accurate delivery time.

· 佛山市立鼎科技有限公司 has professional team for precision customized R&D.

· Implementing the strategy of double layer roll forming machine is the strategic requirement for the sustainable and healthy development of Liding Machine. Please contact.

Application of the Product

The double layer roll forming machine developed by Foshan Liding Technology Co.,ltd is widely used in various fields.

With a focus on Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines, Foshan Liding Technology Co.,ltd is dedicated to providing reasonable solutions for customers.