New Tdf Flange Forming Machine for Factory

Product details of the tdf flange forming machine

Quick Overview

By adopting the lean production method, every detail of Liding Machine tdf flange forming machine exhibits exquisite workmanship. The superior material makes the product superb in quality. It has good economic value with a wide market prospect.

Product Description

Compared with products in the same category, tdf flange forming machine we produce is equipped with the following advantages.

Main parameters

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 1000kg

● Quantity: One.

● Manual Expansion

● Powerless transmission,with brake.

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 0.4-0.6mm

● Main motor power: 4kw(servo motor)

● Molding speed: 3-6m/min

● Number of molding groups: 18 groups+5 groups for straightening

● Shaft diameter and material: ¢ 42mm, 45# steel

● Great wall type plywood: plate thickness 35mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

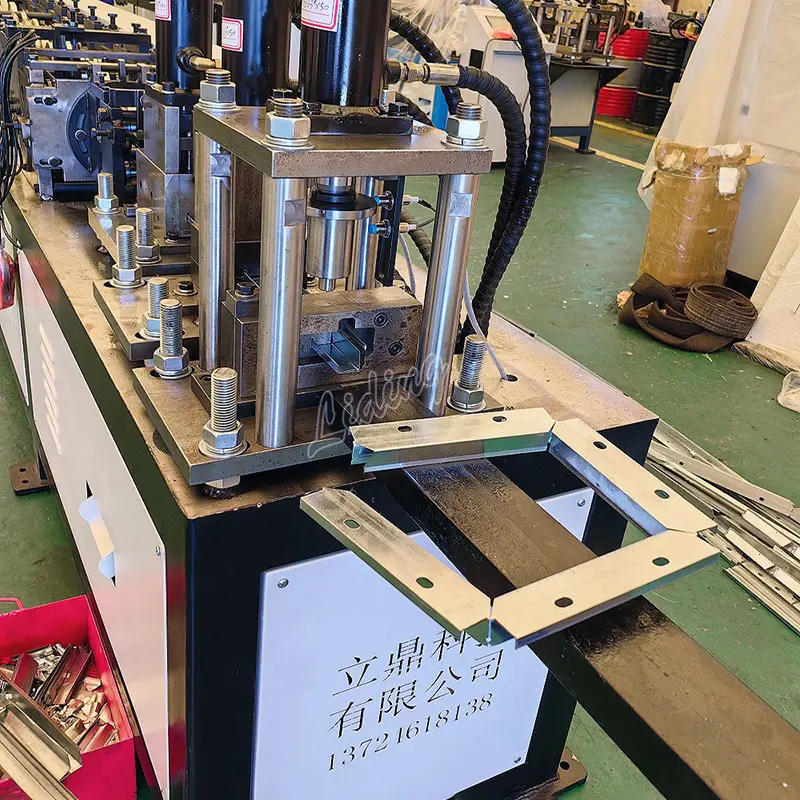

Cutting off parts

● Hydraulic system, hydraulic motor 2.2KW, three stations cylinder

● 1 set of punching molds, 1 set of 90 degree angle cutting molds, 1 set of waste cut-off molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopting online encoder to detect the stopping and cutting.

Run out table

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting length way

● Electronic control box adopts fully sealed ventilation cooling device.

● Control system power supply adopts overload protection.

● Adopt shutdown cut-off mode

Workflow

Decoiling - Roll Forming - Punching round holes - 90 degree notch - cut off - finish

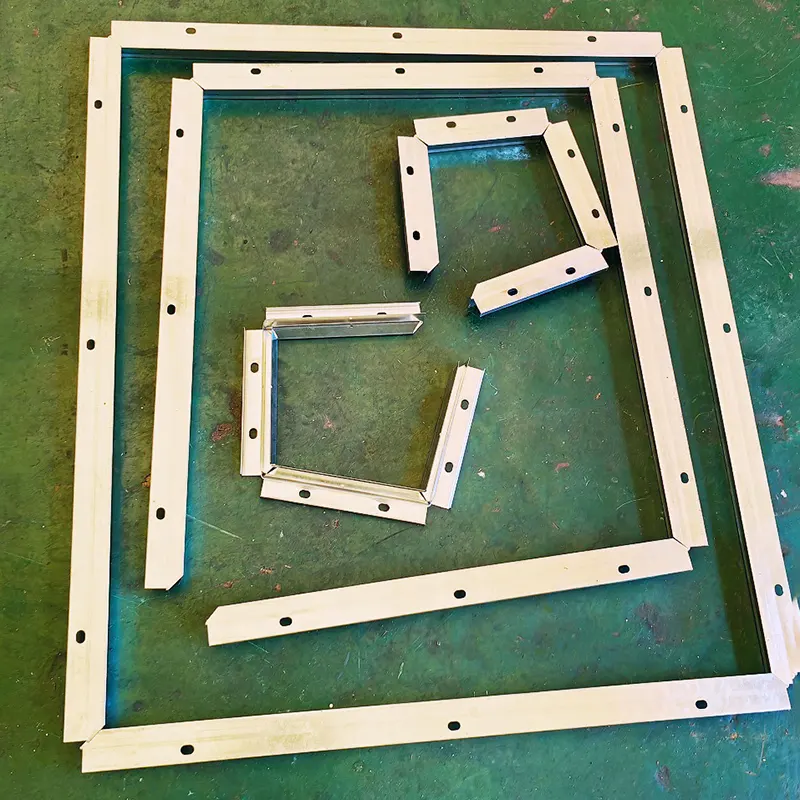

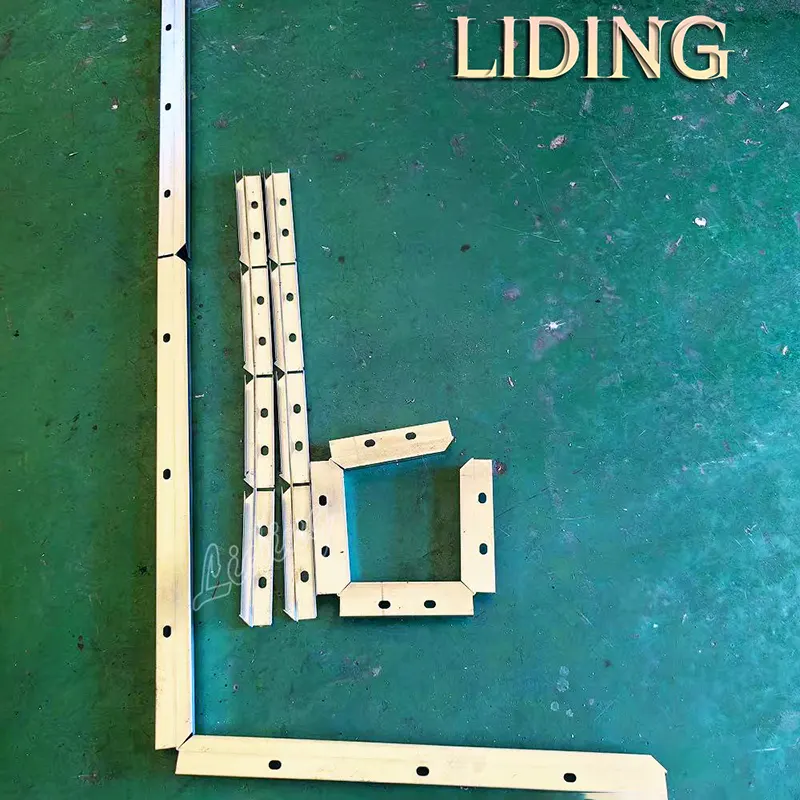

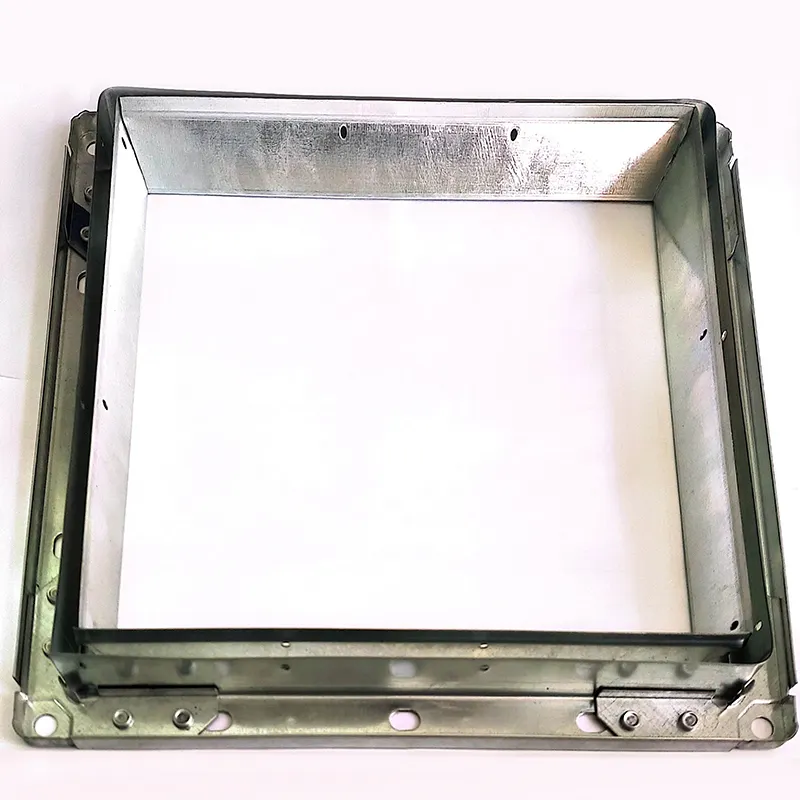

Product display

Company Information

佛山市立鼎科技有限公司 is a modern company in the industry. The main business includes production, processing and sales of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. Foshan Liding Technology Co.,ltd has been constantly providing high-quality and excellent services for customers to meet their demand. We sincerely welcome people from all walks of life to come to make cooperation, common development and a better future.