New Rolling Shutter Forming Machine in many styles for Industrial

Products Description

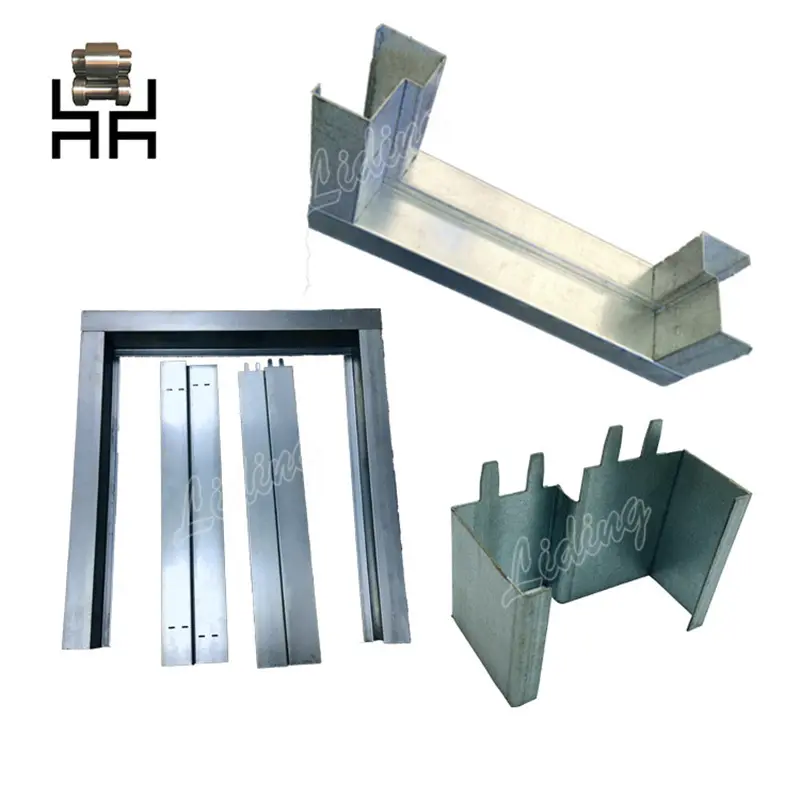

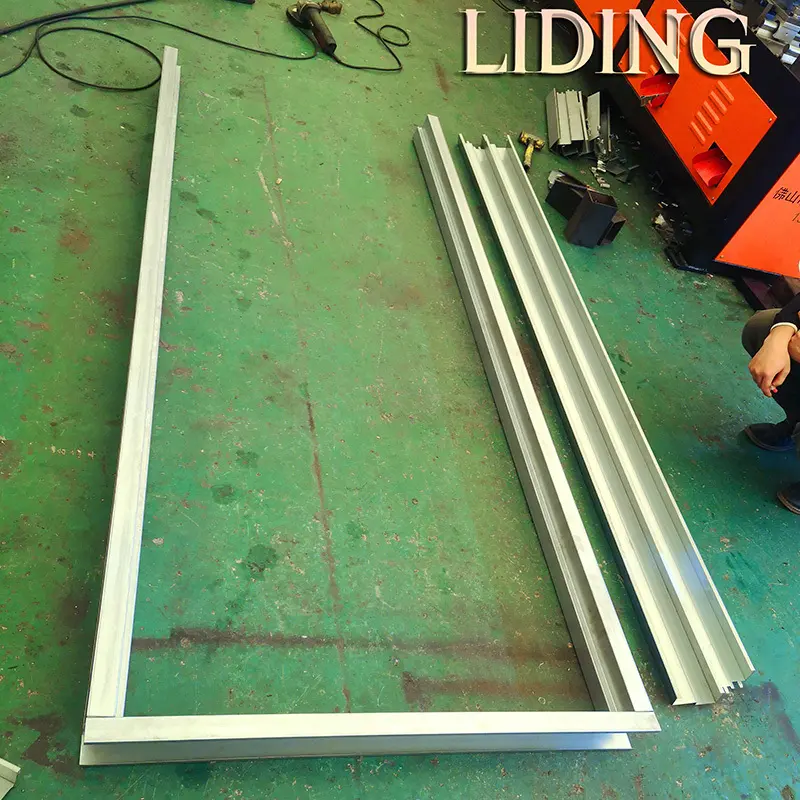

Fireproof Metal Steel shelf Door Frame Making Machine cold roll forming machine:The biggest advantage of the door frame forming machine lies in continuous non-stop operation, high-speedproduction, and unified product standards, because the plate type of the door frame is more complex, the traditionabending machine processing is time-consuming and laborious, more dependent on manual, resulting in higproduction cost. Cold forming machine solves this problem, making the door frame processing become simple, hasbeen recognized by a number of well-known enterprises in the market.

Product Specifications

Upright Window Metal Steel shelf Door Frame Making Machine cold roll forming machine details:

● Feeding material: aluzinc/galvanized steel/colored steel coil/or as customer request

● Material thickness: 0-1.2mm

● Main motor power: 5kw

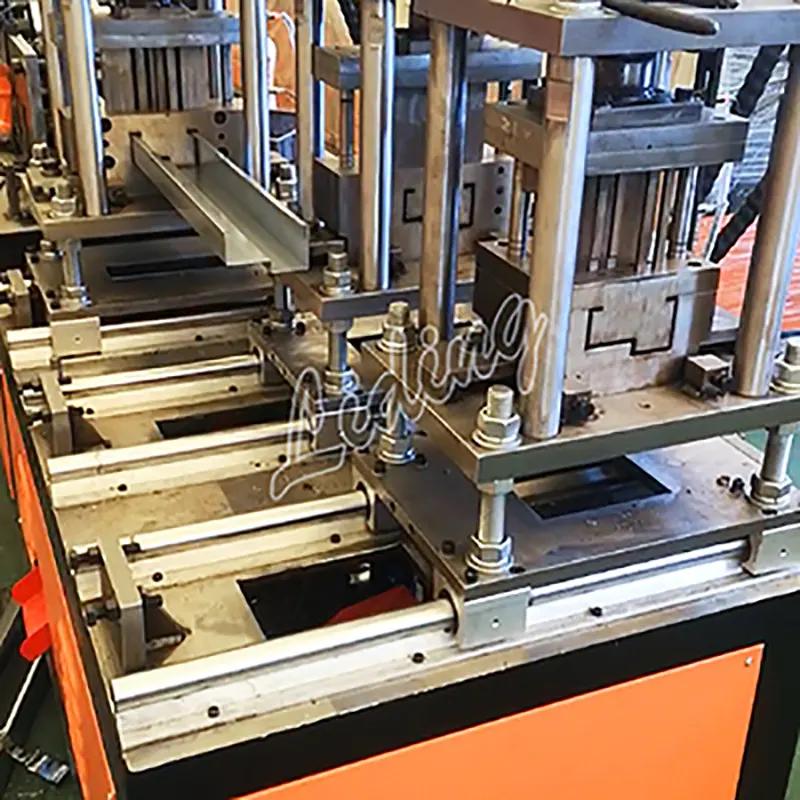

● Number of molding groups: 22 groups+ 5 groups Straighten

● Cutting blade: Cr12MoV with heat treatment

● Main frame:steel plate welding

● Side plate thickness:30mm

● Shaft diameter and material: ¢48mm, 45# steel with quenched and finely ground

● Control systerm: PLC control system with touch screen

● Roller driven type:Chain & gear transmission

Producing process

Decoiling → Roll forming →Punching & Cutting→Run-out table

|

No

|

Item

|

Date

|

|

1

|

Manual Decoiler

|

2 ton

|

|

2

|

Roll Forming Machine

|

1 set

|

|

3

|

Right Punching Mold

|

1 Set

|

|

4

|

Left Punching Mold

|

1 set

|

|

5

|

Straight Cutting Mold

|

1 set

|

|

6

|

Run Out Table

|

2 m

|

|

7

|

PLC controller

|

PLC control system with touch screen

|

Details Images

25 years of production experience to provide customers with solutions

Product display

Company Advantages

· Liding Machine rolling shutter forming machine is manufactured with a beautiful design by using innovative technology.

· The results showed that there are good comprehensive properties in rolling shutter forming machine.

· 佛山市立鼎科技有限公司's products are all 100% guaranteed by high quality foreign brands.

Company Features

· 佛山市立鼎科技有限公司 is committed to this rolling shutter forming machine industry and has extensive manufacturing expertise.

· We have many years of experience in rolling shutter forming machine development, research and production of scientific and technological personnel.

· 佛山市立鼎科技有限公司's constant pursuit is to provide quality services to domestic and foreign merchants. Please contact.

Application of the Product

Our rolling shutter forming machine is widely used in industry.

Based on the actual needs of our customers, we provide a one-stop solution for them with the purpose of rational allocation of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines.