Metal Stud and Track Roll Machine Pressure Vessel - for Sale - Liding Machine

Product details of the metal stud and track roll machine

Product Specification

Core Components: Pressure vessel, Motor, Bearing, Gearbox, PLC

Dimension(L*W*H): 5000*800*1200mm

Control system: PLC(imported Brand)

Warranty of core components: 1 Year

Voltage: 380V

Quick Overview

Liding Machine metal stud and track roll machine is fabricated utilizing premium raw materials that are sourced from reputable vendors. With the implementation of the quality inspection system, all defects of the products are eliminated completely. Known for its excellent features, this product is highly regarded in the market.

Product Information

Compared with other same kind of products in the market, Foshan Liding Technology Co.,ltd's metal stud and track roll machine is equipped with the following outstanding advantages.

Products Description

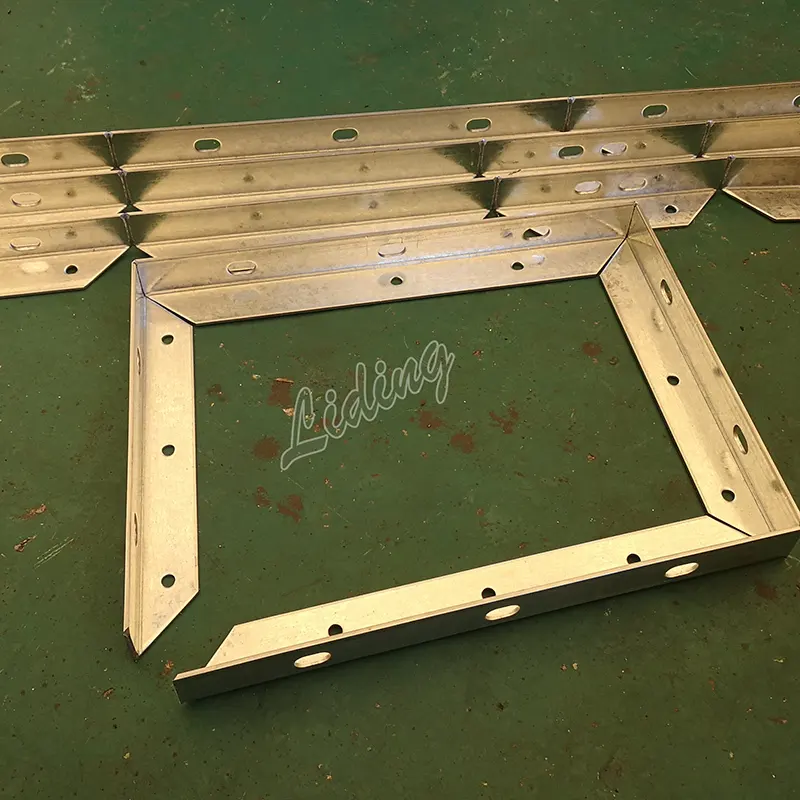

L Angle profile roll forming machine

Application

Angle steel can be used in blower frames or suspended metal and drywall ceiling or drywall partition systems.

Workflow

Decoiling - Roll Forming - (Servo) Punching 45° Angle - Punching Vertical Edge Hole - Punching Flat Edge Hole - Cutting (Outer Flange Cutting) - Finish

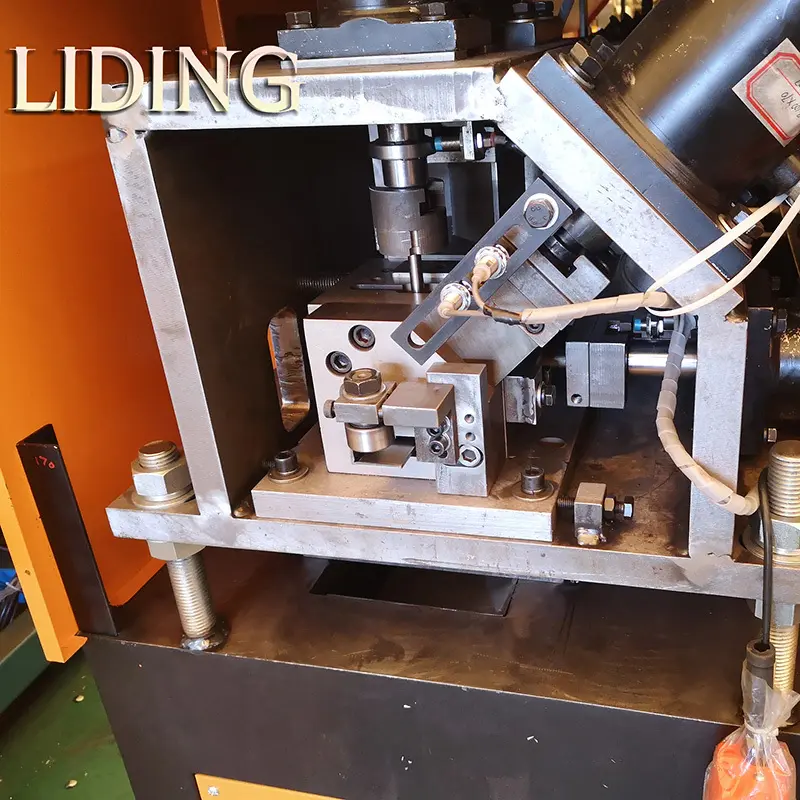

Composition of the machine

● Decoiler,1 set

● Forming machine,1 set

● Mold stations,4 set

● Angle-cutting mold,1 set

● Punching molds (combination of interchangeable cores),2 sets

● Cutting mold,1 set

● Hydraulic cutting system, 1 set

● PLC control 1 set

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 2.0mm

● Main motor power: 7.5kw

● Forming speed: 0-6m/min

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: gear transmission.

● Control system: PLC control

● Machine net weight: about 3tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 4m*0.8m*1.5m

● Forming roll material: Cr12MoV

Cutting off parts

● One set of hydraulic system, hydraulic motor 7.5KW, pressure 15Pa, four stations oil cylinder

● 3 sets of punching molds, 1 set of non-cutting molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping cutoff

Product display

Company Information

佛山市立鼎科技有限公司 (Foshan Liding Technology Co.,ltd) is a company whose main business is to manage Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. Foshan Liding Technology Co.,ltd adheres to the management concept of 'quality, innovation, and mutual benefit'. Under the guidance of the core value, we are always responsible, dedicated, united and proactive. Relying on the advantages of technology and talents, we constantly improve our core competitiveness and strive to gain an invincible position in the fierce competition. The final goal is to become an influential enterprise in the industry. Foshan Liding Technology Co.,ltd has a group of senior engineers to form a technical team. Moreover, we have many experienced production personnel. All this builds a stable foundation for vigorous development. With Internet technology, we provide a one-stop solution for practical and effective implementation of related problems encountered in the process of purchasing products.

If you want to know more relevant product information, feel free to contact us. We are dedicated to serving you.