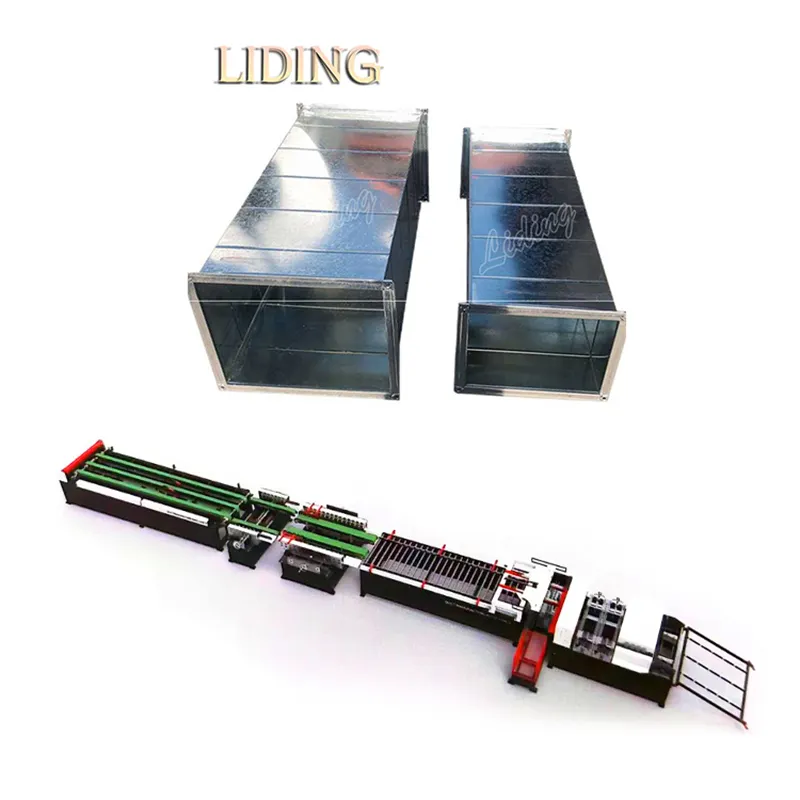

Liding Machine Rectangular Duct Machine Rectangular Duct Machinefactory Price

Product details of the rectangular duct machine

Product Information

rectangular duct machine from 佛山市立鼎科技有限公司 creates a novel product style through innovations in the terms of material and out-look design. The strict quality control system is conducted to ensure the quality of the product. 佛山市立鼎科技有限公司 has gone out and build its rectangular duct machine production bases in Foreign Countries.

Main features

● Uncoiling of fixed length sheet material;

● Angle iron flange, can directly complete the flat type right angle edge, joint angle pressing;

● P-bone flange, co-plate self-forming flange is completed automatically. Is currently a new domestic fully functional, excellent performance, high degree of automation of a new automatic production line of air duct, the whole line of production running speed of up to 10m / min, production efficiency than other similar equipment significantly improved, from the plate material uncoiling to the final air duct reel bone GDF common plate flange, bending all automated.

Product characteristics

Automatic air duct production line Adopt linear structure, reduce the board transfer time, high production efficiency, fold square servo robot feeding, accurate positioning, especially in processing "mouth" type duct, the advantage is obvious.

Only one person needs to operate two people to take away the pipe. The production line features: small volume, low energy consumption, easy to relocate, high efficiency, etc., and can produce various specifications of factory rectangular air duct.

The computer control system adopts an independent operating table, which is luxurious and fashionable; the control system has a closed-loop feedback system and a set of industrial grade servo motors to ensure smooth and accurate operation.

Technical parameters

● Material Galvanized sheet

● Plate thickness Galvanized plate (0.6~1.2mm)

● Roll width 1300mm (widest)

● Running speed 10m/min (adjustable)

● Longest sheet 3000mm

● Shortest sheet 600mm

● Sheet length error range ±1mm/2000mm

● Air duct bending error range ±1mm/2000mm

● Control system Japanese imported full computer numerical control

● Main power supply 380V 50Hz 3 phase

● Production line power about 17KW

● Operating power 24V 50Hz 3 phase

● Hydraulic pressure Max. 14MPa

● Pneumatic pressure 0.5MPa

● Mainframe length approx. 7M

● Width 4000mm

Performance characteristics

The line is capable of long-term stable and continuous operation under the following conditions:

● 380V±10%, 50Hz±10% of three-phase AC power

● Ambient temperature: 0~40 degrees Celsius

● Relative humidity: 55~85%

Production line composition:

● Decoiler 1 set

● Main machine (Leveling,beading,angle notching,shearing) 1 set

● Movable auto Pittsburgh lock forming machine 1 set

● A robot for material clutch,positioning and transferring platform,1 set

● 20mm Duplex PDF/GDF flange machine 1 set

● 30mm Duplex PDF/GDF flange machine 1 set

● Automatic PDF/GDF folding machine 1 set

● Servo motor material feeding platform and hydraulic folding

● Control system 1 set

● Hydraulic system 2 sets

Production line composition

1. Decoiler

The shaft of feeding device is made of 45# steel, and the upper roller of feeding shaft is covered with rubber. 45# steel is processed by tempering treatment, which has enough strength and rigidity. The frame and with square tube and channel steel group welding. Then after aging treatment, so as to ensure the stability in the process of use. The feeder is equipped with a 1.5KW motor, which is driven by a reduction device. After the circuit control, it realizes the function of automatic control of discharging, releasing and pointing feeding, which plays a good role in protecting the surface of the sheet material and avoiding the phenomenon that the general discharging machine damages the material edge.

2. Main machine (Leveling,beading,notching,shearing)

(1)Leveling

The leveling machine adopts the general leveling technology and unique structure design, the working roller material 45# steel, after tempering, electroplating and other reasonable process treatment, the surface performance is good, its rigidity, deflection, surface roughness and other mechanical properties greatly improved, thus playing an important role in the leveling of the surface state and flatness of the plate material.

(2)Beading

The beading adopt the shape of five parallel lines, and the pressing tendon ring is made of high quality steel with heat treatment, which can meet the pressing tendons of the steel plate within 1.2mm thickness, and can form the shape with five lines of curvature and angle at one time, so that the steel of the formed plate is greatly enhanced.

(3)Notching

The shear angle part is located at the end of the leveling machine, which can be adjusted freely according to the width of the sheet. It is very convenient to remove and change the upper and lower dies, and when you need to punch and cut different angles and shapes, you only need to change the upper and lower dies. The power adopts hydraulic system.

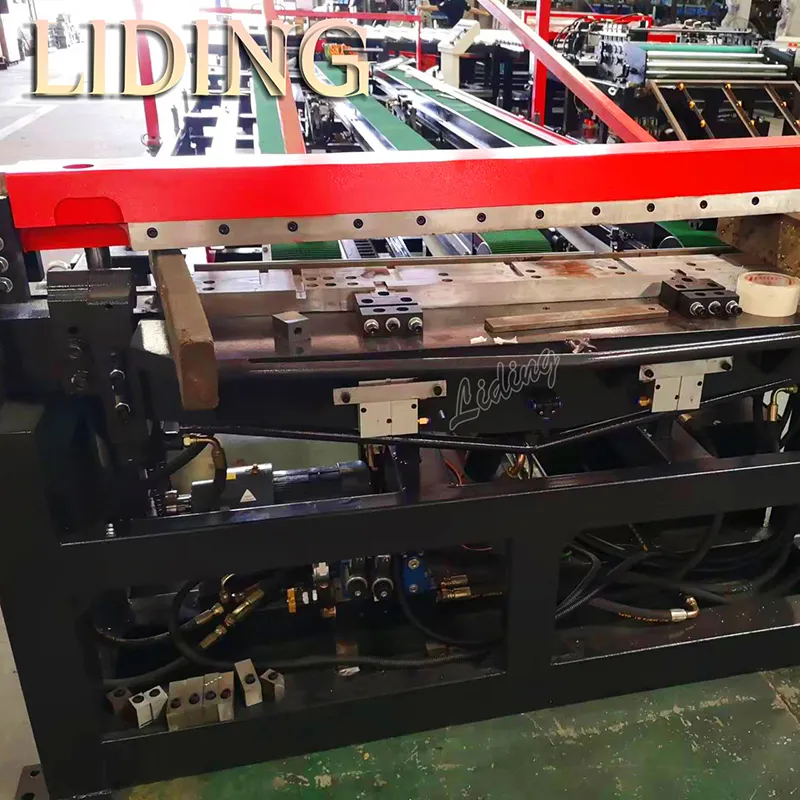

(4)Fixed length shearing

Shearing machine to achieve separate shear plate under the function; plate material forward to the set shear length, the upper beam pressure, while the shear beam action. Hydraulic automatic shearing, transmission balance, shearing tool material using high-quality tool material 9Crsi, shear mouth without burrs and tool life, quick replacement, adjusting the shear gap is very convenient.

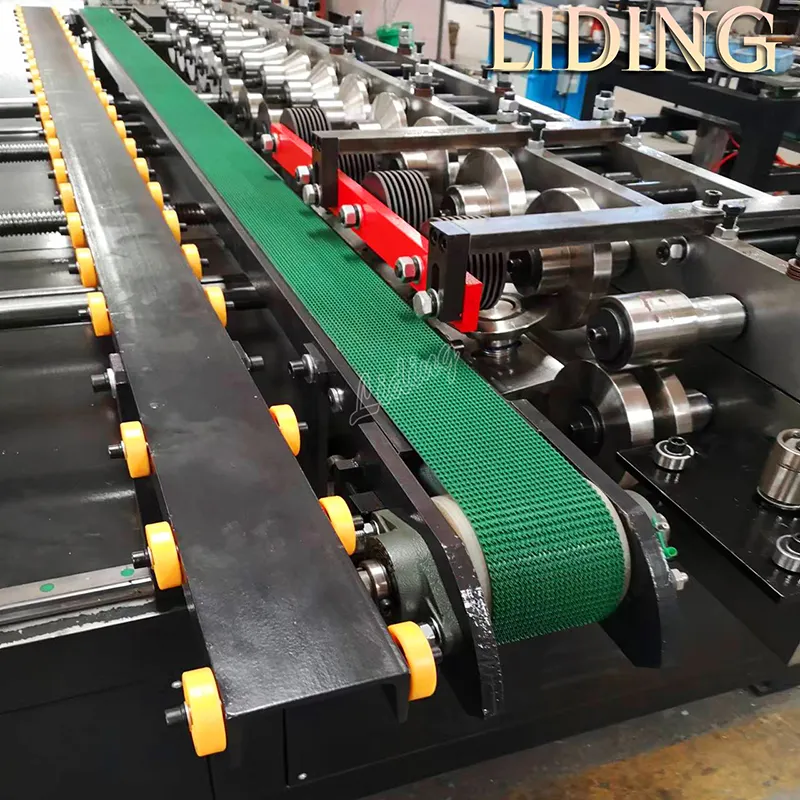

3. Movable auto Pittsburgh lock forming machine

Pittsburgh lock forming machine adopts new displacement type reel bone, one-time forming Pittsburgh lock, when the sheet material smoothly reaches the set length, Pittsburgh lock forming machine automatically starts from left to right, the sheet material enters Pittsburgh lock forming machine after forming the required Pittsburgh lock shape, when Pittsburgh lock shape is completed ,then touching the limit switch, the Pittsburgh lock forming machine returns to the original position to complete a cycle. The sheet enters the

next flange machine process.

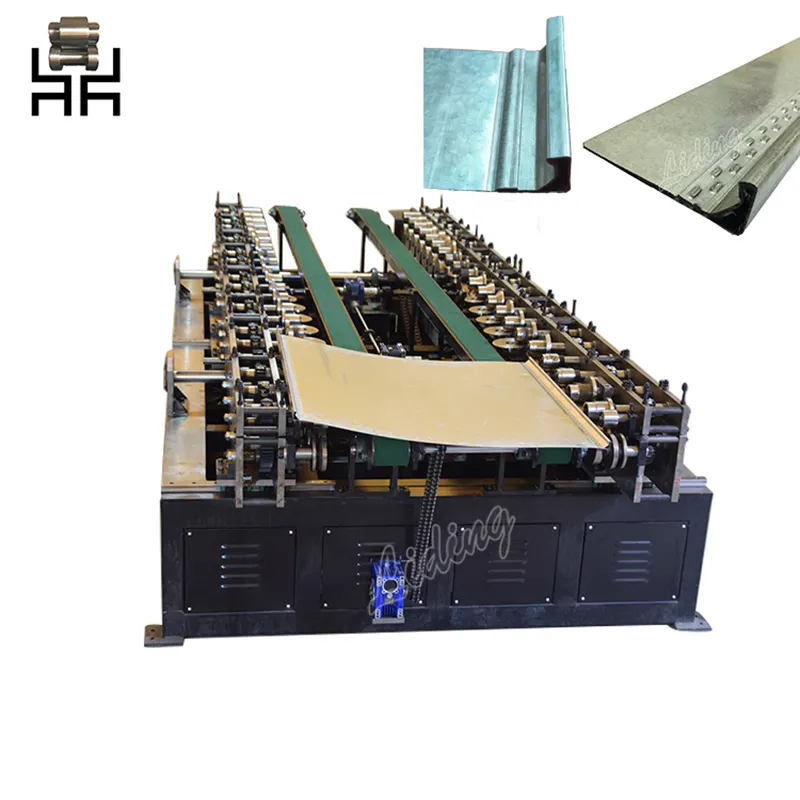

4.20mm & 30 mm Duplex PDF/GDF flange machines,2 sets

(forming width of up to 1500mm adjustable)

Duplex PDF/GDF flange machine consists of two sets of rolls. When different flanges are needed, it is only necessary to adjust the required flange then it can be used. Roll by GCr15 steel processing, heat treatment, CNC lathe finishing, roll surface hardness up to HRC58 ~ 60. forming width of up to 1500mm adjustable, adjust the loosening of the lock nut, shaking the hand wheel to the required width and then lock the nut can be, two sets of rolls set fixed, another set of linear guide, can be adjusted through the nut, screw width. Two sets of rolls are synchronized by the drive shaft. So the sheet material through the Duplex PDF/GDF flange machine guide plate into the rolls, complete the flange forming.

GDF common plate flange

5. Servo motor material feeding platform and hydraulic folding

This is a new type of PDF/GDF hydraulic bending machine with a manipulator. The manipulator consists of fixed frame, manipulator, Yaskawa servo motor, Mitsubishi PLC drive and belt transfer device. Its function is to convey the sheet material into the bending machine after forming by flange forming machine. The material is clamped by the manipulator, and the servo motor controls the fixed length feeding to the bending machine.

Hydraulic bending machine, pressing bending are controlled by hydraulic and electrical systems, bending using hydraulic drive, double-acting throttle valve for speed regulation, smooth work, small impact. When finishing Pittsburgh lock forming, forming flange, the robot will be pushed the sheet to the bending machine and set length position, the lower beam upward compression the sheet, bending machine bend the sheet, complete the plate material bending " "right angle bone shape process, the plate material continues to move forward to the set position, complete various models of bending, after completing the duct from the bending machine then manually removed. Pressing, bending hydraulic cylinders complete bending with compact structure, great bending effect.

Production line structure appearance diagram

6. Equipment noise measurement standards

A weighted sound pressure level LPA ≤ 82dB(A)

A weighted sound power level LWA ≤ 94dB(A)

7. Equipment implementation standards

GB 17120-1997 "Forging Machinery Safety Technical Conditions

JB 8781-1998 "Shearing Machine Safety Technical Requirements

JB/T 1829-1997 "Forging Machinery General Technical Conditions

GB 10923-1997 "forging machinery precision inspection general rules

ZB J62033-90 Technical Conditions of Folding Machine

Product display

Company Feature

• Foshan Liding Technology Co.,ltd is able to provide professional and thoughtful services for consumers for we have various service outlets in the country.

• Foshan Liding Technology Co.,ltd develops ourselves by relying on the resources in the domestic and foreign market. This enables us to further improve market share and continuously provide high-quality products.

• Foshan Liding Technology Co.,ltd has a group of employees who have been engaged in the production of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines for many years. This provides a strong guarantee for the product quality.

• Foshan Liding Technology Co.,ltd was founded in After the development for we have become a leader in the industry.

It is an honor for Foshan Liding Technology Co.,ltd to receive your consultation. We look forward to reaching long-term partnership with you.