Liding Machine Purlin Roll Forming Machine Manufacturer Cr12mov Purlin Roll Forming Machine Manufacturersupply

Product details of the purlin roll forming machine manufacturer

Product Specification

Voltage: 380V

Production Capacity: 8 m/min

Rolling thinckness: 2.0mm

Weight: 3000 kg

Roller material: Cr12mov

Product Overview

With the help of our skilled experts, Liding Machine purlin roll forming machine manufacturer is exquisite in its workmanship. After our strict quality control, all defects of the product have been thoroughly removed. Liding Machine has acquired the certifications of purlin roll forming machine manufacturer, and provides one-stop solution with quality inspection.

Product Information

The purlin roll forming machine manufacturer mainly promoted by Foshan Liding Technology Co.,ltd have been further improved in the past through the technical improvement, which is reflected in the following aspects.

Products Description

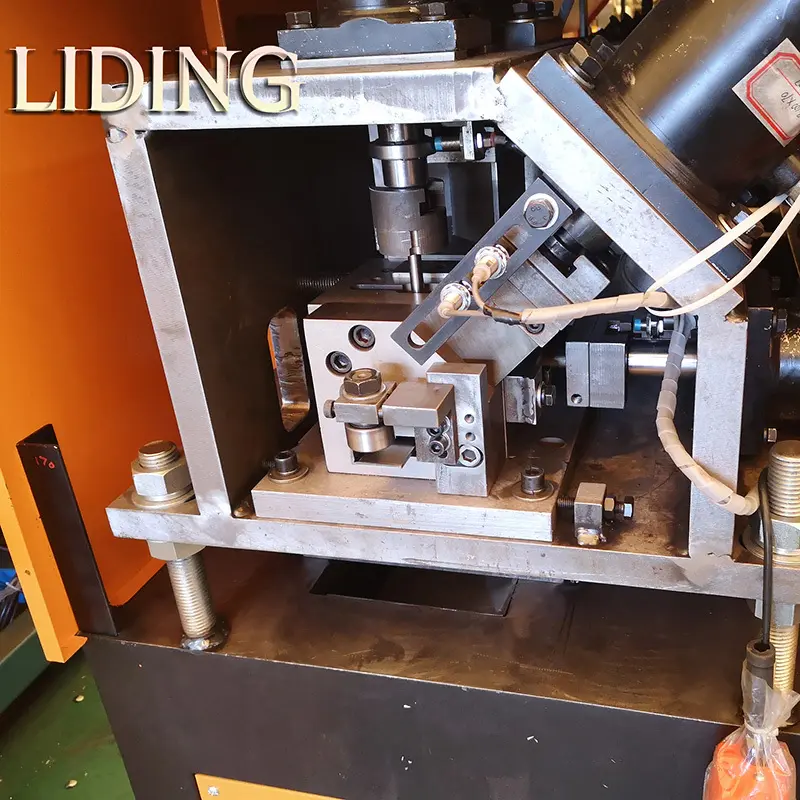

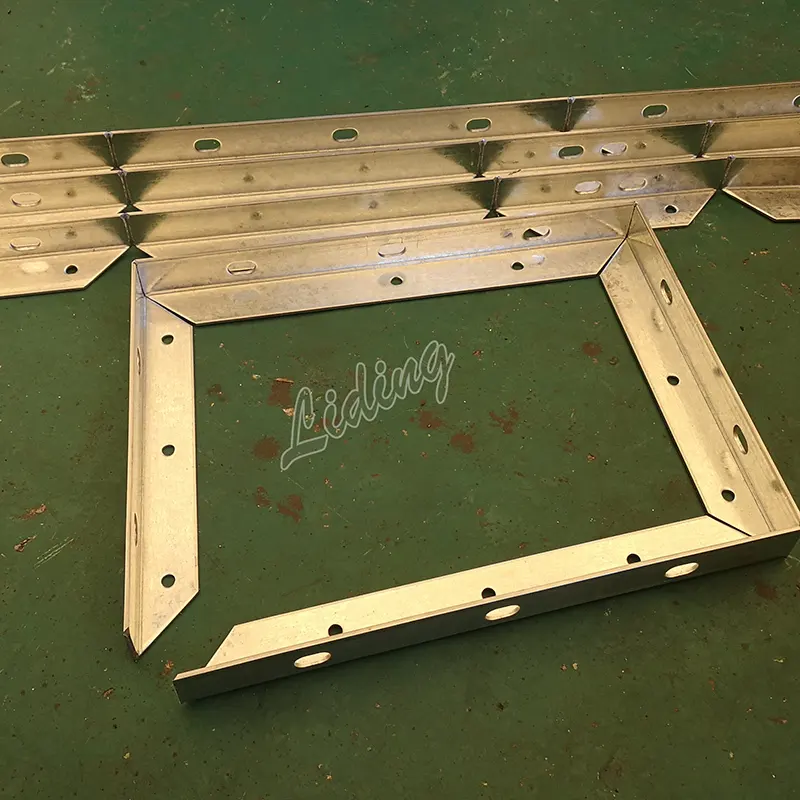

L Angle profile roll forming machine

Application

Angle steel can be used in blower frames or suspended metal and drywall ceiling or drywall partition systems.

Workflow

Decoiling - Roll Forming - (Servo) Punching 45° Angle - Punching Vertical Edge Hole - Punching Flat Edge Hole - Cutting (Outer Flange Cutting) - Finish

Composition of the machine

● Decoiler,1 set

● Forming machine,1 set

● Mold stations,4 set

● Angle-cutting mold,1 set

● Punching molds (combination of interchangeable cores),2 sets

● Cutting mold,1 set

● Hydraulic cutting system, 1 set

● PLC control 1 set

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 2.0mm

● Main motor power: 7.5kw

● Forming speed: 0-6m/min

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: gear transmission.

● Control system: PLC control

● Machine net weight: about 3tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 4m*0.8m*1.5m

● Forming roll material: Cr12MoV

Cutting off parts

● One set of hydraulic system, hydraulic motor 7.5KW, pressure 15Pa, four stations oil cylinder

● 3 sets of punching molds, 1 set of non-cutting molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping cutoff

Product display

Company Introduction

佛山市立鼎科技有限公司, lying in fo shan, is a professional company. We focus on the business of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. Our company perseveres in the philosophy of 'high quality, sustainable development', and sticks to the spirit of 'being faithful and people-oriented'. We are committed to becoming an outstanding enterprise in the industry. Foshan Liding Technology Co.,ltd has a team of high-quality talents composed of many industry experts and R&D backbones to contribute to the production of more quality products. We have been engaged in the production and management of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines for many years. For some problems encountered by customers in the procurement, we have the ability to provide customers with a practical and effective solution to help customers solve problems better.

We provide you with high-quality products and look forward to your inquiry.