Liding Machine Elbow Cold Forming Machine Hydraulic Cutting Elbow Cold Forming Machinefrom China

Company Advantages

· Liding Machine elbow cold forming machine has a design that satisfies design standard.

· The product has passed strict quality testing in each procedure under the quality management system.

· Maintenance service during the first year of using is free for our elbow cold forming machine.

Product Description

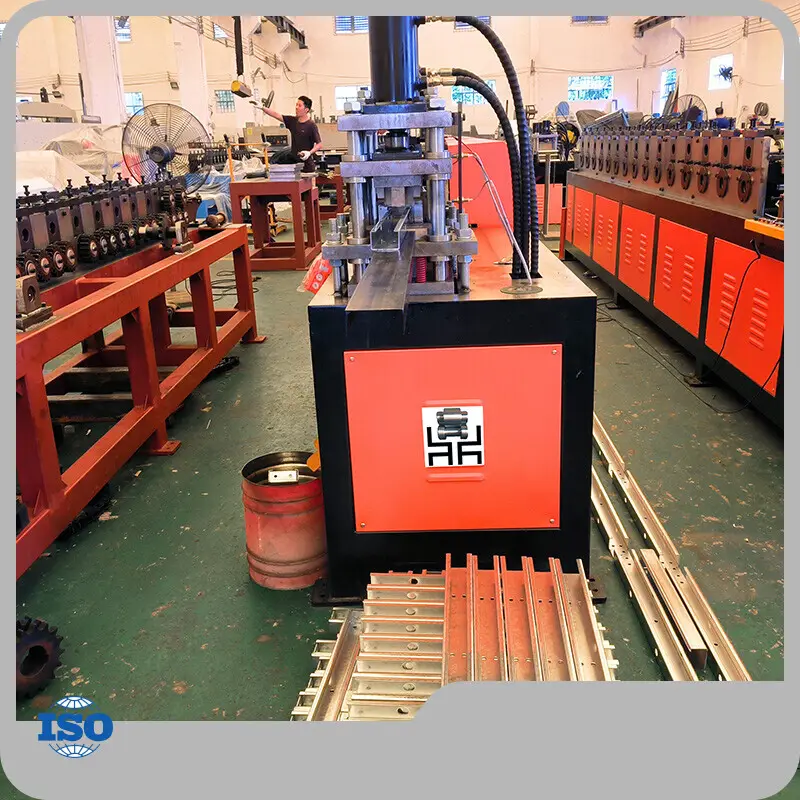

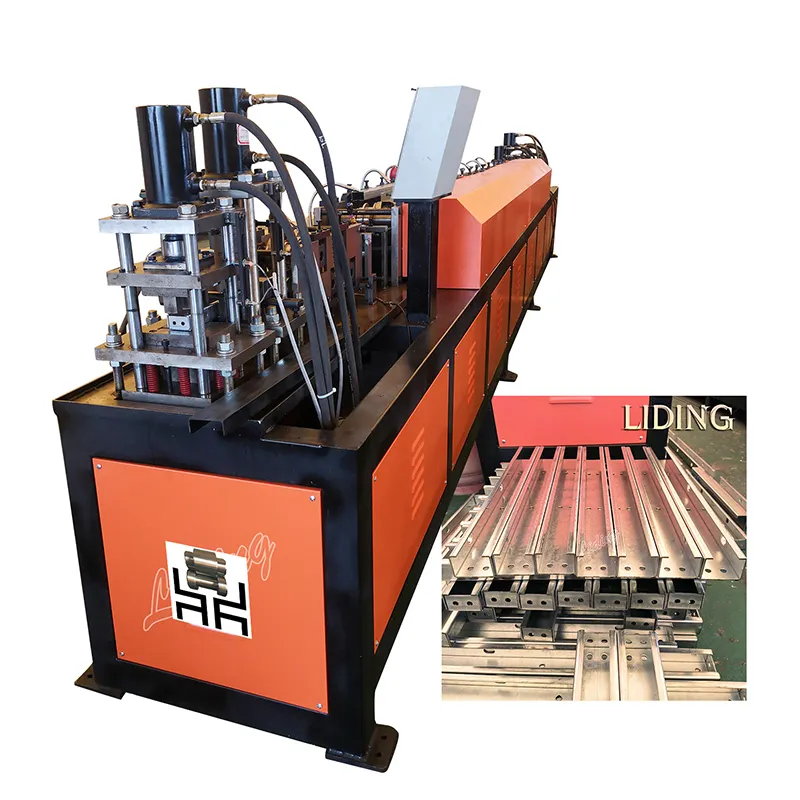

C Profile Air Blower Base roll forming machine

2-in-1 C profile machine: 2 profile production available as an option

Production process

Powerless uncoiling - servo flat feed -hydraulic punching round hole & punching square hole mold (4 sets), cut off the tail material - cold roll forming - cut off - cut off folding - finish

|

Serial number

|

composition

|

data

|

|

1

|

Manual Decoiler

|

Max. bearing load capacity 2000kg

|

|

2

|

Servo leveling feeder

|

Feeding speed: 15 meters / min

|

|

3

|

Hydraulic punching machine

|

25-ton cylinder hydraulic station with a power of 7.5kw

|

|

4

|

Punching mold, 4 sets

|

Mold material CR12MOV

|

|

5

|

Tail material cutting mold

|

1 set

|

|

6

|

Cold roll forming machine

|

15 stations

|

|

7

|

Forming and cutting mold

|

material Cr12MOV

|

|

8

|

Cutting and folding mold

|

material Cr12MOV

|

|

9

|

Hydraulic system

|

7.2KW

|

|

10

|

PLC automatic control equipment

|

Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

|

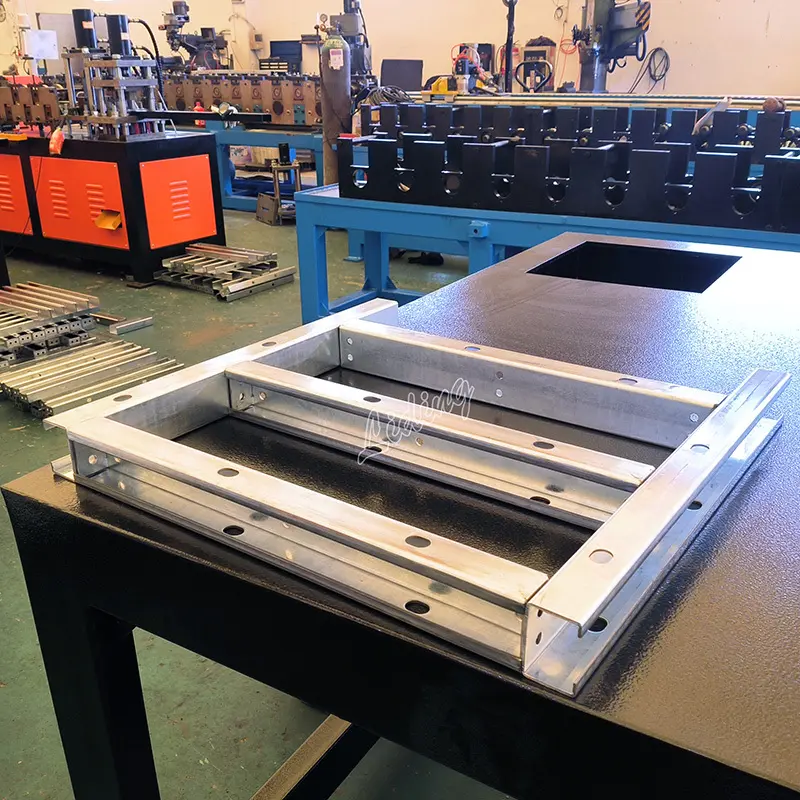

Application

Machine-produced profiles for blower bases.

Specification

|

Condition

|

New

|

|

Production Capacity

|

0-8m/min

|

|

Place of Origin

|

China,Guangdong

|

|

Brand Name

|

Liding

|

|

Voltage

|

380V 50Hz 3phases

|

|

Dimension(L*W*H)

|

6000*800*1200mm

|

|

Weight

|

4000kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Rolling thinckness

|

2.0-2.5mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

C Profile Air Blower Base roll forming machine

|

|

Roller material

|

cr12mov

|

|

Cutting blade material

|

CR12mov

|

|

Servo motor

|

7.5kw+7.5kw

|

|

Transmission

|

Chain & gear transmission.

|

Basic Configuration

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 300mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Adopt Panasonic PLC, human-machine interface control, and domestic inverter for speed regulation.

● The main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counts the length of the way

● Electronic control box adopts fully sealed ventilation cooling device.

● Adopt shutdown cut-off mode

NC numerical control Leveling & feeding machine

● Material width: 200mm

● Maximum thickness of material: 2.5mm

● Flat feed shaft 11 rollers

● Servo motor: AC1.5KW

● Feeding speed: 15 meters / min

Punching mold,4set

● Width of material: unspecified

● SMaterial thickness 2.0-2.5mm

● Mold material CR12MOV

● Hydraulic system: a set of 25-ton cylinder hydraulic station with a power of 7.5kw;

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 0-2.5mm

● Main motor power: 5kw

● Molding speed: 0-8m/min

● Number of molding groups: 15 groups

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

Cutting off parts

● Adopt online fiber optic detection to cut off the machine.

● Cut off mold 1 set, material Cr12MOV

● Cutting and forming mold 1 set

Product display

Company Features

· 佛山市立鼎科技有限公司 rounds up the best elbow cold forming machine brand for high performance and high style.

· Liding Machine is of strong strength to ensure the quality of elbow cold forming machine.

· The development track of 佛山市立鼎科技有限公司 cannot be separated from a center. This center is a customer. Inquire online!

Application of the Product

Foshan Liding Technology Co.,ltd's elbow cold forming machine is widely used in the industry.

With rich manufacturing experience and strong production capability, Foshan Liding Technology Co.,ltd is able to provide professional solutions according to customers' actual needs.

Enterprise Advantages

Our company has established a high-quality and high-efficiency production team. With years of production experience, our members can solve problems in the process of production effectively.

Our company always insists on the idea that service comes first. We are committed to fulfilling customers' needs for service by providing the most cost-effective solutions in logistics service.

Our company worships the enterprise spirit of 'practical, hardworking and responsible' and follows the business philosophy of 'integrity, pragmatism and mutual benefit'. We rely on advanced technology, perfect management, excellent quality and considerate service to provide high-quality products and services.

Established in Foshan Liding Technology Co.,ltd has been continuously introducing competitive products in the rapid development for years. Now we have become a leader in the industry.

Based on the joint efforts of all employees, Foshan Liding Technology Co.,ltd's Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines are sold well in major cities in China and also exported to multiple countries and regions such as the Middle East, South Asia, Australia, Eastern Europe, North America, and South America.