Hvac Duct Manufacturing Machines Liding Machine Brand

Company Advantages

· The Liding Machine hvac duct manufacturing machines is manufactured using high quality of raw materials that are procured from our trusted vendors.

· We continuously monitor and adjust production processes to ensure product quality meets customer and company policy requirements.

· 佛山市立鼎科技有限公司 has excellent customer service representatives available to help you out by phone.

Profile

Workflow

Decoiling - Cold Roll Forming - Cutting - Finishing

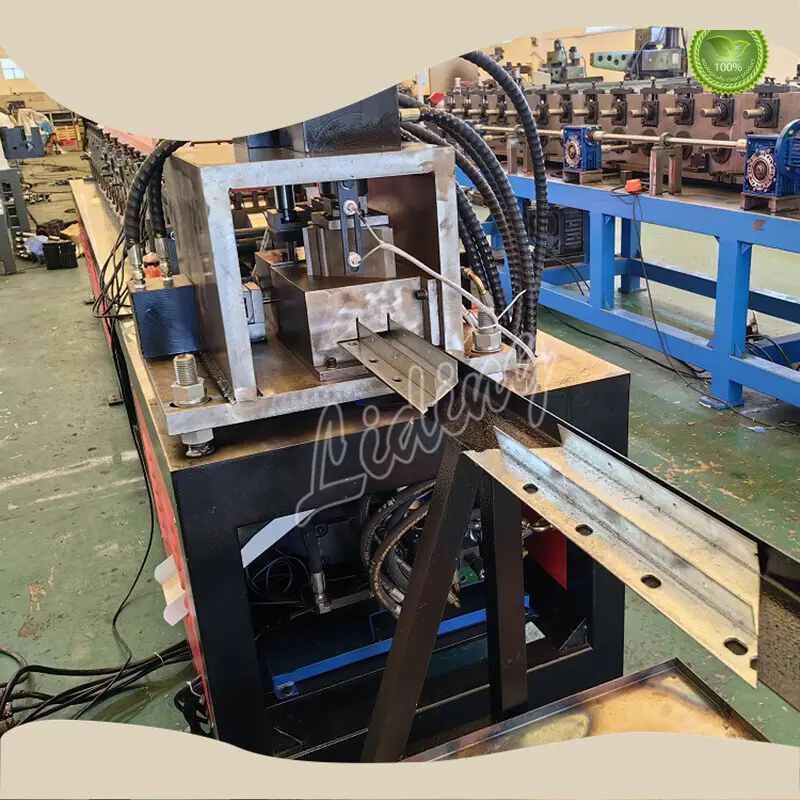

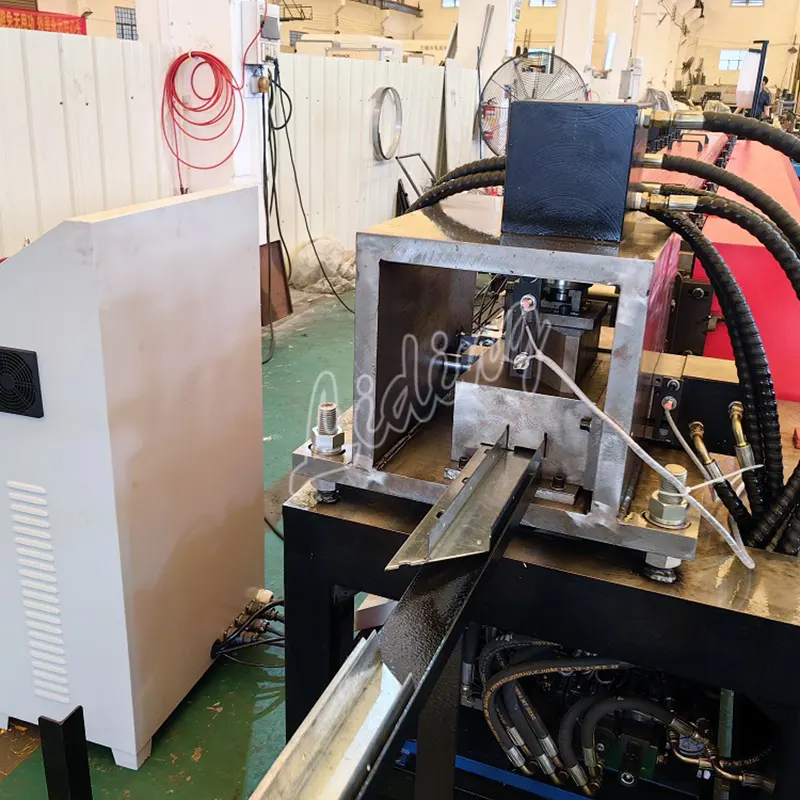

Composition of the machine

● Decoiler,1 ton

● Forming machine,18 groups

● Hydraulic cut-off mold,3 set

● Run out table,1 set

● PLC control cabinet,1 set

Basic Configuration

I. Electric Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 1000kg

● Quantity: One.

● Manual Expansion

● No power transmission,with brakes.

II. Forming machine(5)

● Applicable materials:Galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 11kw

● Molding speed: 1-3m/min

● Number of molding groups: 18 groups+5 groups straightening

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 3 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

V. Cutting off parts(1)

● With a set of hydraulic system device

● Hydraulic motor 7.5KW, one station oil cylinder

● With 1 set of flange hole molds, 2 sets of spigot hole molds, 1 set of 45-degree cut-off molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping and cutting.

VI. Run out table

● Flat length 1 meters

● Flat table structure using square tube angle iron composition.

Basic Configuration

VII. PLC computer control cabinet(3)

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting method

● Electronic control box adopts fully sealed ventilation cooling device.

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

Product display

Company Features

· 佛山市立鼎科技有限公司 is a pioneer in supply hvac duct manufacturing machines of high quality.

· With a perfect system and varied hvac duct manufacturing machines, Liding Machine covers a wide range of products.

· Adhering to the corporate philosophy of “Dedicating to the success of our customers”, we are united to create innovative products with global competitiveness. Get info!

Application of the Product

hvac duct manufacturing machines developed and produced by our company can be widely used in various industries and professional fields.

With a focus on Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines, Foshan Liding Technology Co.,ltd is dedicated to providing reasonable solutions for customers.

Enterprise Advantages

Foshan Liding Technology Co.,ltd constantly optimizes management system. Our elite team with both ability and virtue is established to provide continuous motivation for our company's long-term development.

With the highest sincerity and the best attitude, Foshan Liding Technology Co.,ltd strives to provide consumers with satisfactory services in line with their real needs.

Seeing into the future, our company will always insist on the core values of 'passionate and dedicated, determined and progressing'. Based on our enterprise tenet of 'being practical and innovative to serve the society', we provide high-quality products and services for customers.

Foshan Liding Technology Co.,ltd was created in and we have developed for years.

Our company takes its city as the product sales center, and aims to expand the sales coverage in a global way to increase its market share.