Hot Metal Stud and Track Roll Machine Ordinary Product Liding Machine Brand

Product details of the metal stud and track roll machine

Product Specification

Roller material: Cr12mov

Shaft material: 45# Steel Forging Treatment

Marketing Type: Ordinary Product

Raw material: PPGI PPGL GI GL

Product Overview

Liding Machine metal stud and track roll machine is designed to incorporate aesthetics and practicality. The products are durable and have long service life. Our metal stud and track roll machine meets the needs of multiple industries and fields. The product has favorable market prospects and development potentials.

Product Introduction

Compared with peer products, our metal stud and track roll machine has more obvious advantages and they are reflected in the following aspects.

Products Description

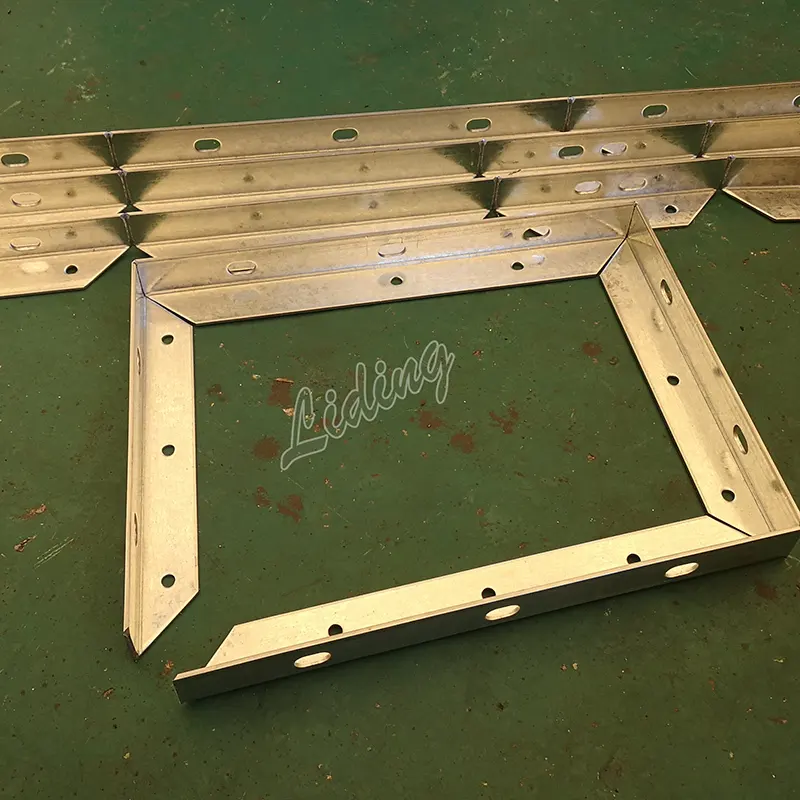

L Angle profile roll forming machine

Application

Angle steel can be used in blower frames or suspended metal and drywall ceiling or drywall partition systems.

Workflow

Decoiling - Roll Forming - (Servo) Punching 45° Angle - Punching Vertical Edge Hole - Punching Flat Edge Hole - Cutting (Outer Flange Cutting) - Finish

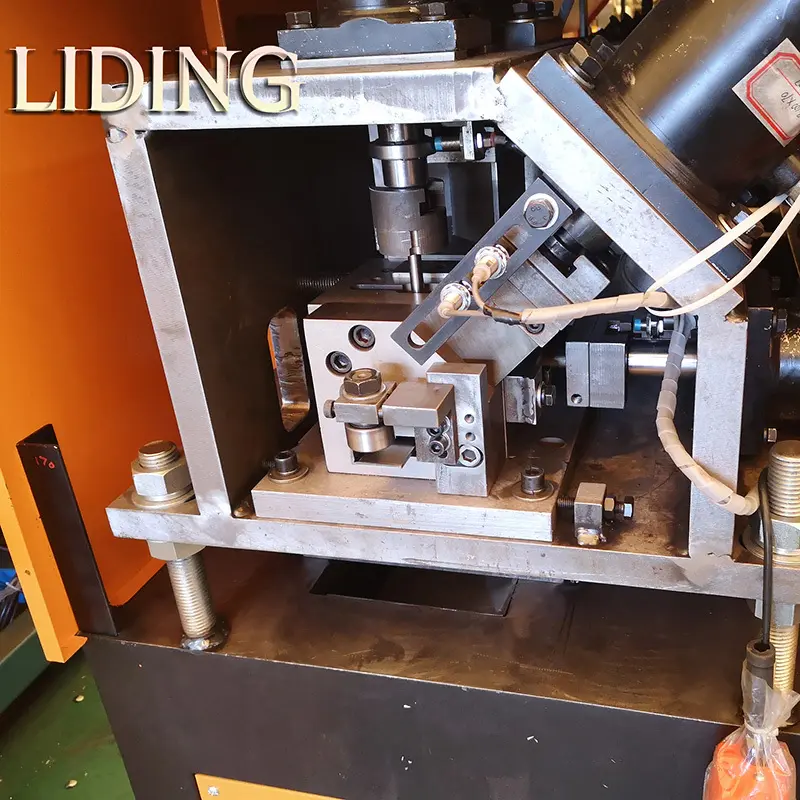

Composition of the machine

● Decoiler,1 set

● Forming machine,1 set

● Mold stations,4 set

● Angle-cutting mold,1 set

● Punching molds (combination of interchangeable cores),2 sets

● Cutting mold,1 set

● Hydraulic cutting system, 1 set

● PLC control 1 set

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 2.0mm

● Main motor power: 7.5kw

● Forming speed: 0-6m/min

● Shaft diameter and material:¢ 56mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: gear transmission.

● Control system: PLC control

● Machine net weight: about 3tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: L*W*H 4m*0.8m*1.5m

● Forming roll material: Cr12MoV

Cutting off parts

● One set of hydraulic system, hydraulic motor 7.5KW, pressure 15Pa, four stations oil cylinder

● 3 sets of punching molds, 1 set of non-cutting molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping cutoff

Product display

Company Information

Doing excellent since its inception, 佛山市立鼎科技有限公司 is a reliable and reputable metal stud and track roll machine manufacturer in the rapidly developing industry. We own advanced manufacturing and testing facilities. 佛山市立鼎科技有限公司 intends to enter the international marketplace by supplying exquisite metal stud and track roll machine and exceptional service. Call!

You are always welcomed for inquiry.