High Endfor Industrial for Factory

Product details of the for industrial

Quick Detail

Liding Machine for industrial is crafted using quality materials in compliance with industry production norms and guidelines. This product has undergone rigorous quality checks before reaching to customers. The product is highly recognized by customers in the market.

Product Introduction

Compared with peer products, our company's for industrial has the following characteristics.

Profile

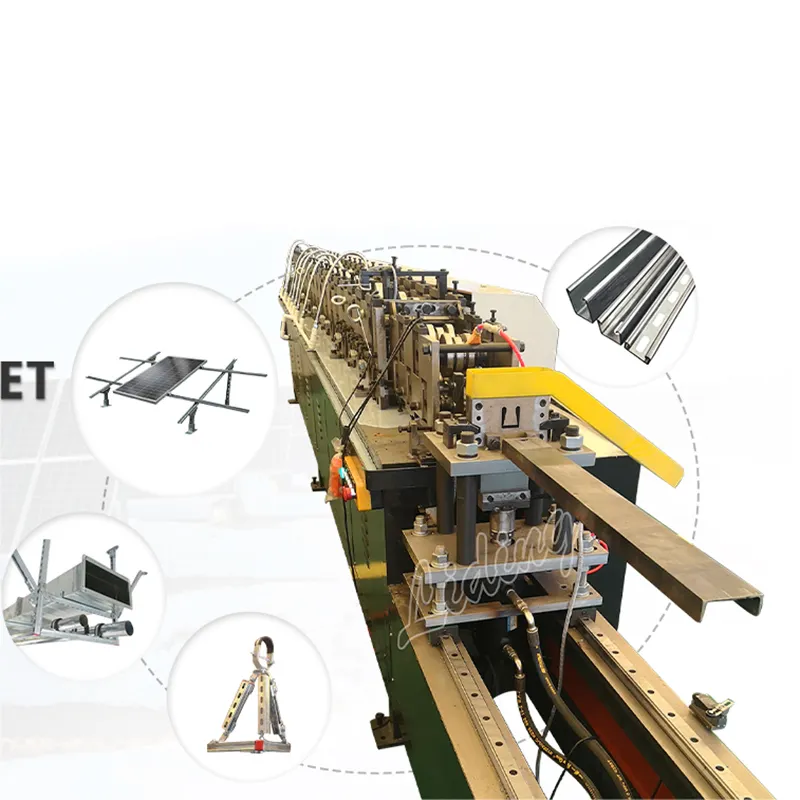

Application

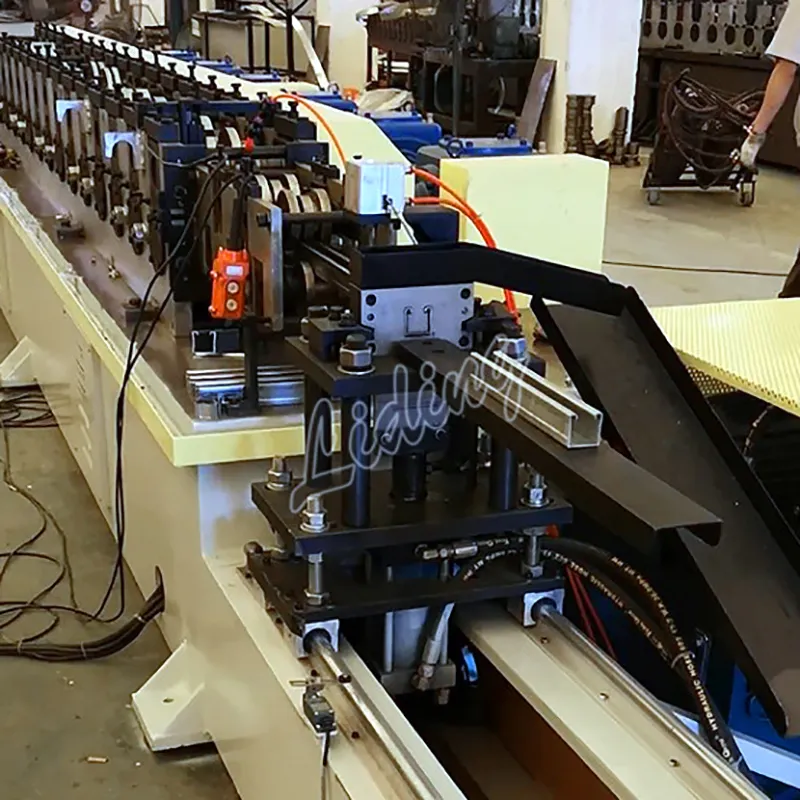

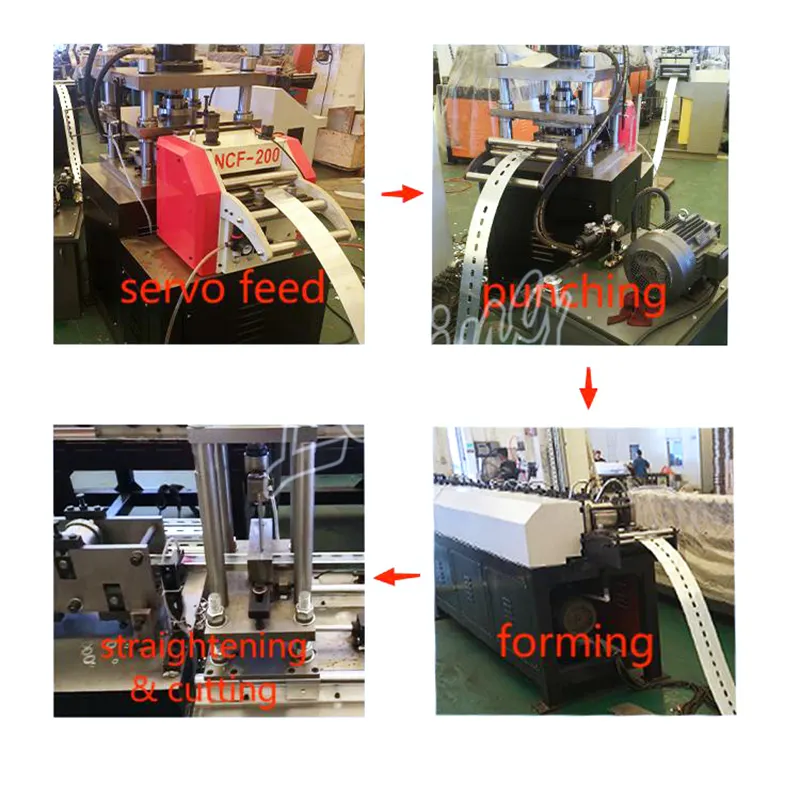

Workflow

Electric decoiling and leveling feed - servo feed - punching and punching teeth - cold roller forming - hydraulic cutting - unloading - finish

Composition of the machine

the whole line is about 24 meters long

● Electric leveling Decoiler(2T),1 set

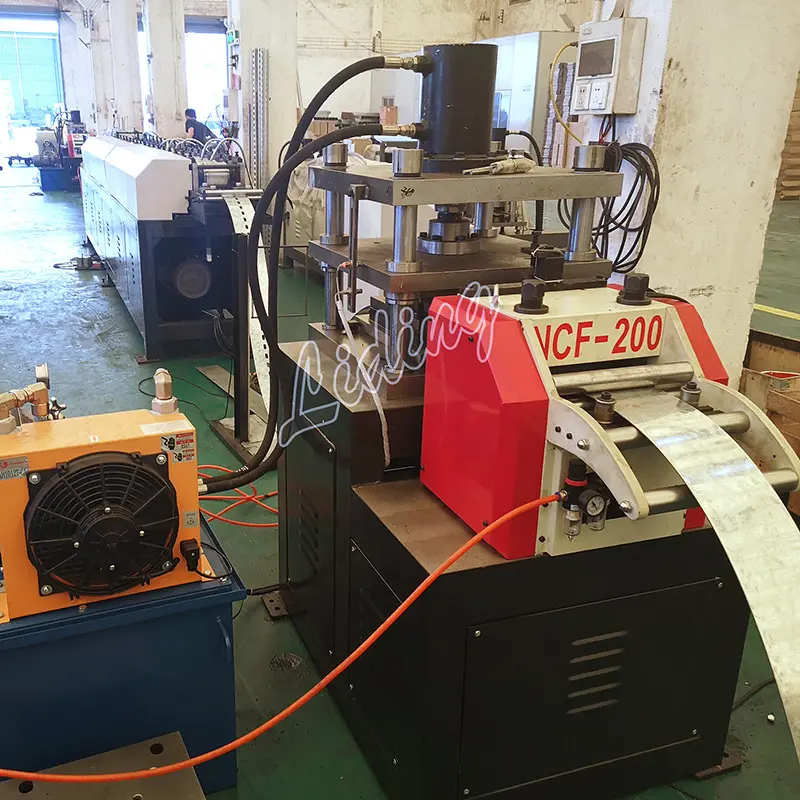

● Servo feeder,1 set

● Hydraulic punching machine,1 set

● Punching molds (41*21, 41*41),2 sets

● Forming machine,1 set

● Hydraulic cut-off mold ,1 set

● Run-out table,1 set

● PLC control cabinet 1 set

Basic Configuration

Electric leveling Decoiler

● Bore diameter 460~520mm.

● Material width 300mm.

● Load weight 2000kg.

● Manual core expansion is used.

● With power transmission .

● Automatic control function.

NC precision electronic numerical control roller feeding machine

● Material width: 200mm.

● Material thickness: 3.0mm.

● Servo motor:AC1.8KW.

● Feeding speed: 10 meters/min.

Hydraulic punching machine 1 set, punching mold 2 sets

● Hydraulic working pressure:16MPA

● Hydraulic motor:7.5KW

● Material width 102-142mm.

● Material thickness 1.5-3.0mm.

● Mold material Cr12MoV.

Basic Configuration

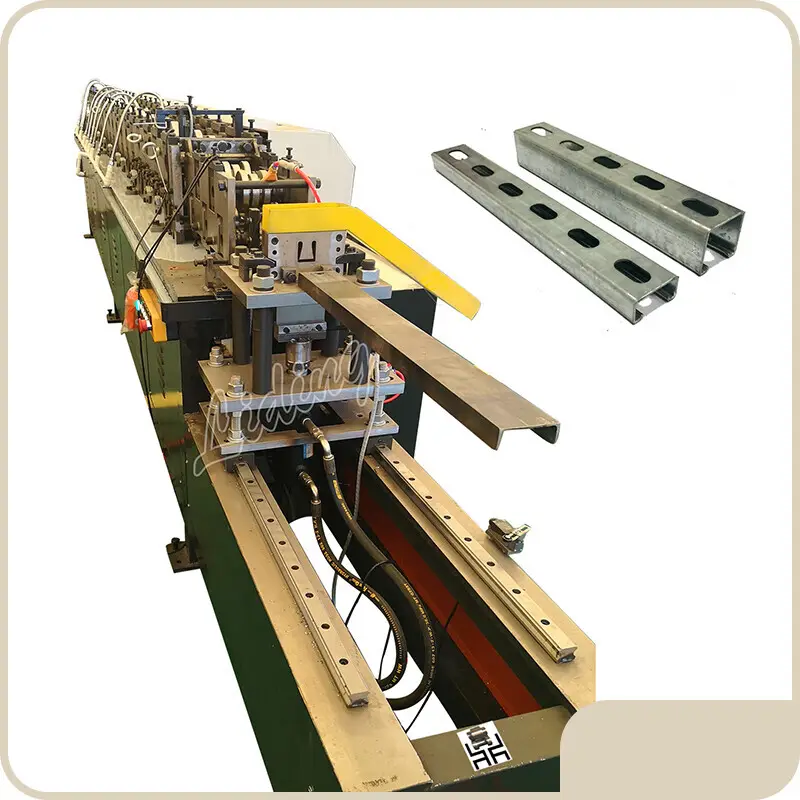

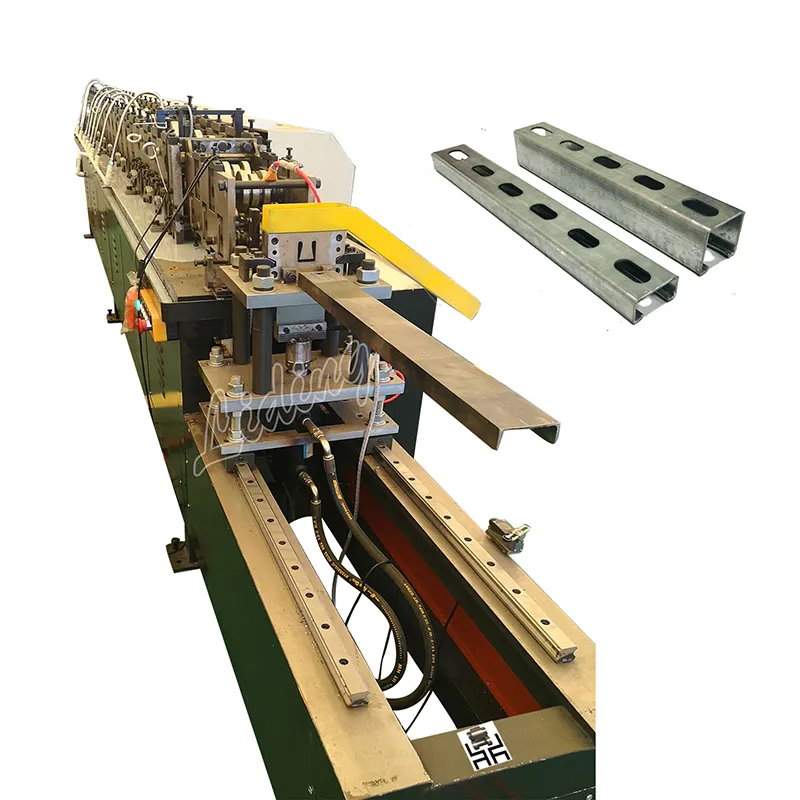

Molding machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:1.5-3.0mm.

● Machine can produce 41*21, 41*41 two specifications, lifting forming module replacement specifications

● Main motor power: 22kw (two motors total 22kw).

● Forming speed: 0-6m/min.

● Bearing: NJ210E Bearing

● Number of forming groups: 21 groups (14 groups for replacement specifications)

● Shaft diameter and material: ¢58mm, 45# steel.

● Tolerance of cut length: 3m+-1.5mm, (cut between hole and hole).

● Transmission: Chain, gearbox steering transmission. (Main drive reduction gearbox: BWD4).

● Control system: PLC control.

● Machine net weight: about 8 tons .

● Voltage: 380V/ 3phase/ 50 Hz.

● Dimensions of forming machine: Approx. L*W*H 7m*1m*1.4m (Frame welded with steel pipe)

● Forming roll material: Cr12MoV.

● Cutting mold material: Cr12MoV Heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● Equipped with a set of hydraulic system unit.

● With two sets of mold cut-off.

● Motor power 4 kW.

● Adopt cylinder control cut-off method.

● Adoption of non-stop cylinder jack cut-off method

Unloading

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

● Pneumatic automatic unloading is adopted.

PLC computer control box

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Automatic measurement: encoder

● Control the length and quantity with PLC. The machine automatically cuts the length and stops when the required quantity is reached.

● Length can be modified

● Control panel: push-button switches, touch screen

Product display

Company Advantages

佛山市立鼎科技有限公司, situated in fo shan, focuses on the production and sales of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. In the business management, our company attaches great importance to quality and credit, and we follow the enterprise spirit of 'optimistic and active, positive and aspirant, innovative and developing'. In order to provide quality product, we continuously enhance our core competitiveness, and gradually implement the development strategy of scale and industrialization. With the quality products, our customers could enjoy a relaxing experience. Our company combines 'introduction' with 'training' to build a high-quality talent team. At present, our company has a number of senior talents who are familiar with product production, enterprise management and capital operation. With many years of practical experience, Foshan Liding Technology Co.,ltd is capable of providing comprehensive and efficient one-stop solutions.

We are willing to go hand in hand with you to create a better future.