High End Cold Roll Forming Machinery for Factory

Product details of the cold roll forming machinery

Quick Overview

The direction cold roll forming machinery will develop towards is to meet your requirements. This product guarantees high quality and excellent performance, as all factors affecting its quality and production performance are immediately detected and then corrected by our trained QC personnel. Our cold roll forming machinery is widely used in industry. Liding Machine has successfully produced cold roll forming machinery in bulk production ensuring the competitive price.

Product Introduction

We are not afraid of customers to pay attention to the details of our cold roll forming machinery.

Main features

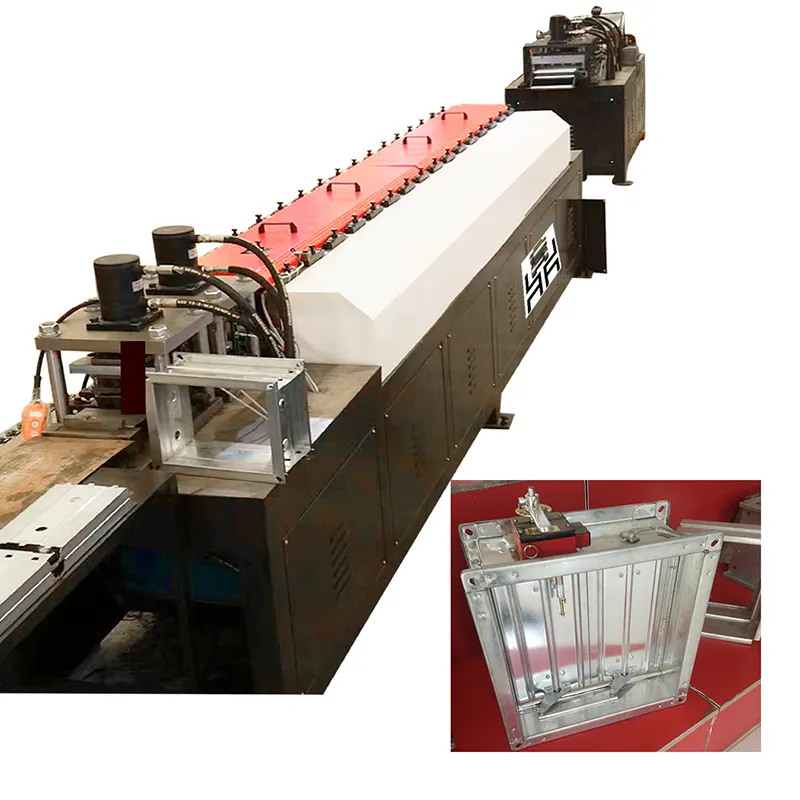

Volume control damper frame Roll Forming Machine Main Features:

1. Fast speed: forming speed of 0-6m/min,can produce 300–400 frame 8 hours per shift by only 1-2 people.

2. High precision: hole distance error ± 0.25 mm, length error ± 0.5 mm, diagonal error ± 0.8 mm.

3. High efficiency: continuous order mode, customers can input multiple order data at one time for continuous production.

4. Good forming effect: specially designed rollers to ensure less abrasion to zinc layer after galvanized sheet is formed.

5. Small bending R: specially designed bending tool as well as pre-punching indentation at the small edge, two processes to ensure that the bending angle is small.

6. Good stability: electrical components adopt international and domestic top brands, the main mechanical parts through careful design and fatigue test, to ensure the stable production of production line in high-intensity and high-load working environment.

7. Simple operation: Computer controlled and easy to learn.

Damper outer frame roll forming Machine Main Technical Parameters

|

Technical parameters and specifications |

|

|

Coil material |

Galvanized Sheet |

|

Material thickness |

1.0-1.6mm |

|

Inner/Outer diameter of coil |

Ф460-Ф520mm/1500mm |

|

Forming speed |

0-6m/min |

|

8, Sheet length error range |

± 0.5mm |

|

Valve body bending error range |

±0.5mm |

|

Control system |

Full computer numerical control |

|

Main power supply |

380V 50Hz 3-phase |

|

Hydraulic pressure Working pressure |

8-12 MPa |

|

system pressure |

16MPa |

|

Pneumatic pressure |

0.6-0.8MPa |

|

Total length of the production line |

About 20 meters |

|

Machine width |

Approx. 1 m |

|

Total power |

About 25KW |

|

Total weight of machinery |

about 8 tons |

Workflow

Damper outer frame forming Producing process:

Decoiling →Servo Feeding& Punching&Cutting → Roll forming →Punching & Cutting→Run-out table

Damper outer frame roll forming Machine Compositions

|

Item |

Date |

|

Decoiler and leveling two-in-one machine |

Load weight 3000kg |

|

NC precision electronic numerical control roller feeding machine |

2KW servo motor |

|

Hydraulic punch&Cutting Modular (3 Stations,with 3 mold) |

Round hole punching molds 1 sets Punching square hole mold 1 set Cutting molds 1 set |

|

Roll Forming Machine |

16 stations, 7.5KW servo motor |

|

Hydraulic punch modular after forming |

2 Stations,with 2 mold |

|

Cutting Modular after forming |

1 Station,with 1 mold |

|

Run Out Table |

4 m |

|

PLC control cabinet |

Famous brand with touch screen |

|

Hydraulic system |

2 set (5.5kw) |

Product display

Company Information

佛山市立鼎科技有限公司 is an excellent company in the country. Our main business is the production and sales of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. Besides the business philosophy of 'innovation and change, pursuit of excellence', our company also adheres to the enterprise spirit of 'being honest and trustworthy, treating people sincerely'. We are dedicated to providing customers with quality products and efficient services. Foshan Liding Technology Co.,ltd's experienced experts and technical teams constantly improve and innovate our products. The product quality is guaranteed by the modern factory and professional production staff. Foshan Liding Technology Co.,ltd insists on providing customers with one-stop overall solution from the customer's point of view.

We have many years of experience in production and sales. And if you are interested in our products, feel free to contact us.