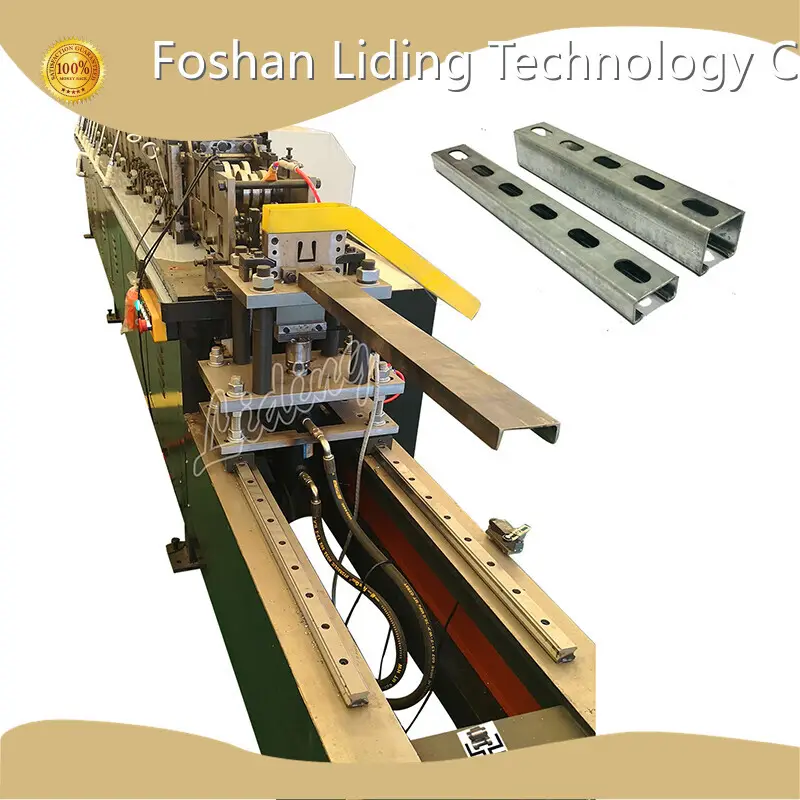

High End C and Z Purlin Machine C and Z Purlin Machine Company

Product details of the c and z purlin machine

Product Description

Liding Machine c and z purlin machine is produced with the well-selected raw materials to ensure each piece in good condition. The product has passed through the extremely harsh quality control and inspection on a basis of quality control plan. This plan is strictly carried out to ensure the high quality of the product. It is highly recommended by the targeted customers.

Profile

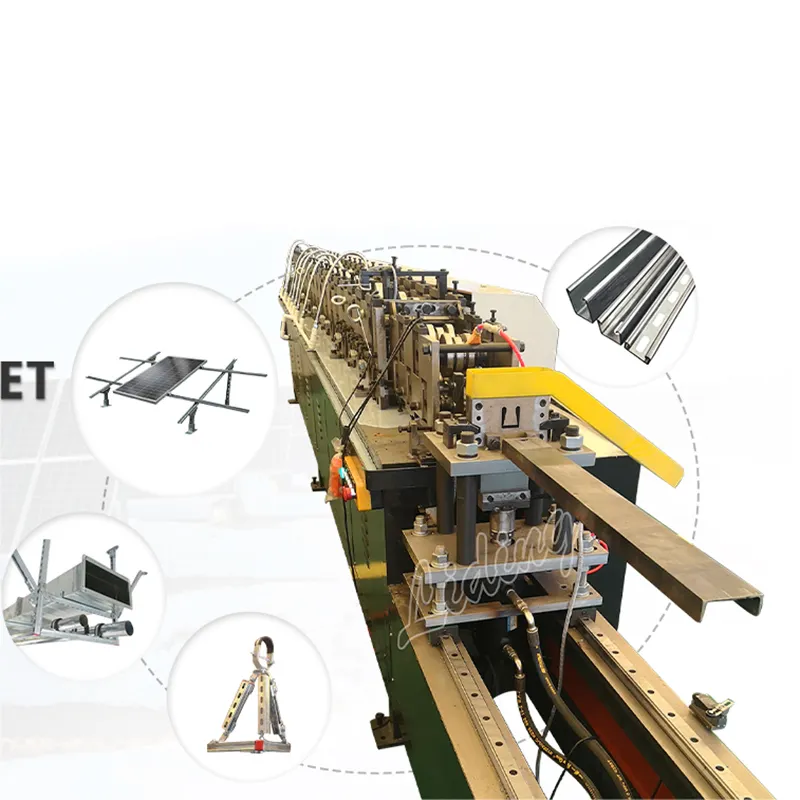

Application

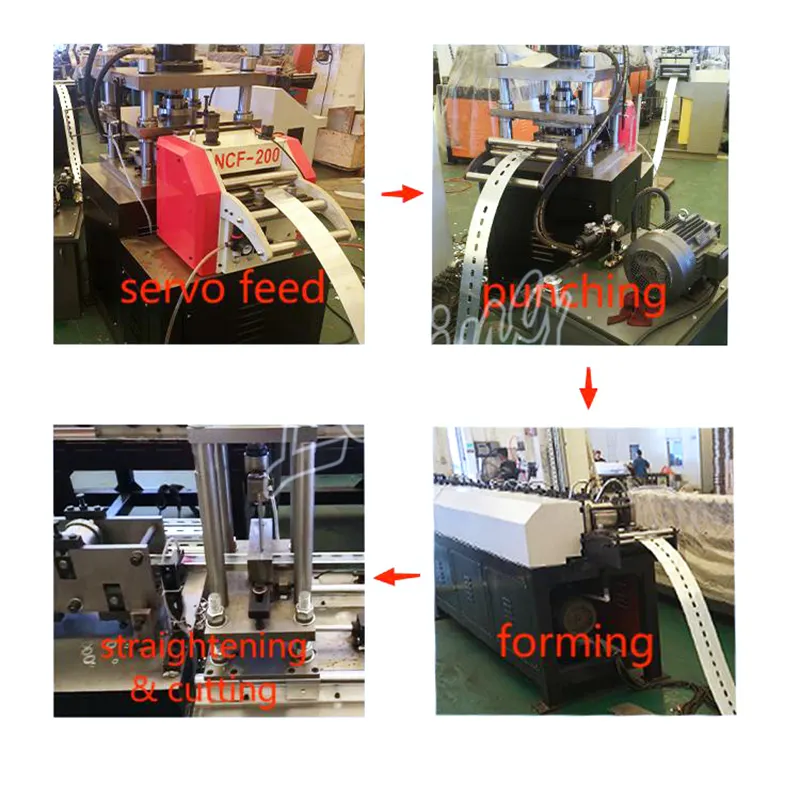

Workflow

Electric decoiling and leveling feed - servo feed - punching and punching teeth - cold roller forming - hydraulic cutting - unloading - finish

Composition of the machine

the whole line is about 24 meters long

● Electric leveling Decoiler(2T),1 set

● Servo feeder,1 set

● Hydraulic punching machine,1 set

● Punching molds (41*21, 41*41),2 sets

● Forming machine,1 set

● Hydraulic cut-off mold ,1 set

● Run-out table,1 set

● PLC control cabinet 1 set

Basic Configuration

Electric leveling Decoiler

● Bore diameter 460~520mm.

● Material width 300mm.

● Load weight 2000kg.

● Manual core expansion is used.

● With power transmission .

● Automatic control function.

NC precision electronic numerical control roller feeding machine

● Material width: 200mm.

● Material thickness: 3.0mm.

● Servo motor:AC1.8KW.

● Feeding speed: 10 meters/min.

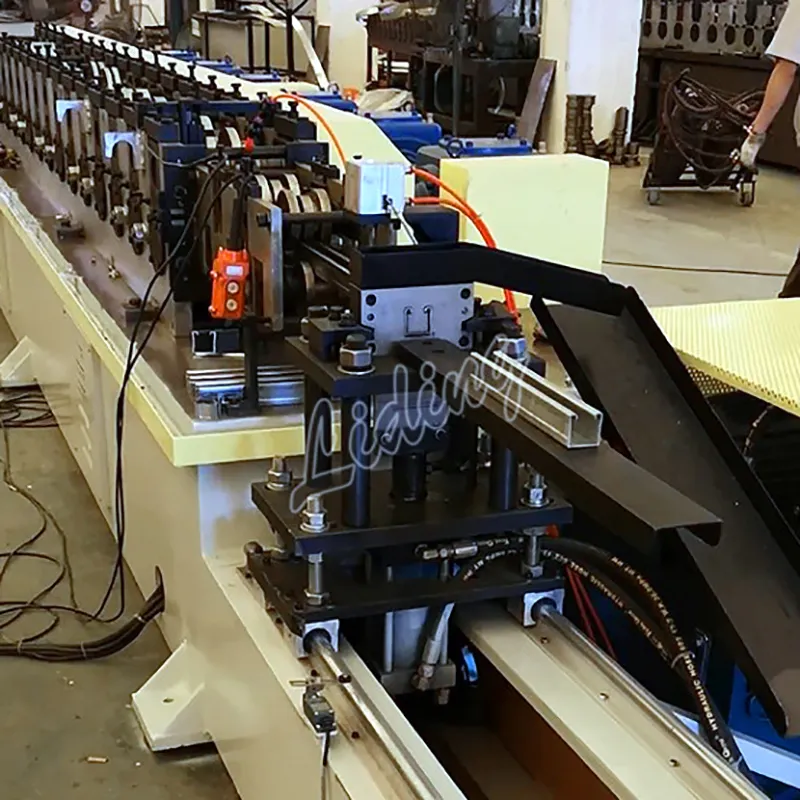

Hydraulic punching machine 1 set, punching mold 2 sets

● Hydraulic working pressure:16MPA

● Hydraulic motor:7.5KW

● Material width 102-142mm.

● Material thickness 1.5-3.0mm.

● Mold material Cr12MoV.

Basic Configuration

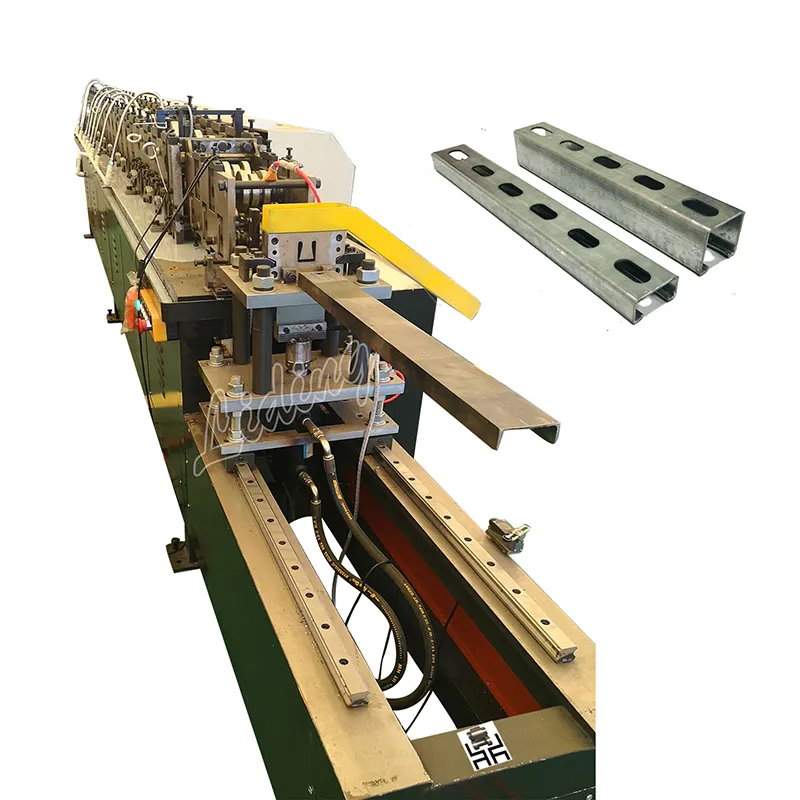

Molding machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:1.5-3.0mm.

● Machine can produce 41*21, 41*41 two specifications, lifting forming module replacement specifications

● Main motor power: 22kw (two motors total 22kw).

● Forming speed: 0-6m/min.

● Bearing: NJ210E Bearing

● Number of forming groups: 21 groups (14 groups for replacement specifications)

● Shaft diameter and material: ¢58mm, 45# steel.

● Tolerance of cut length: 3m+-1.5mm, (cut between hole and hole).

● Transmission: Chain, gearbox steering transmission. (Main drive reduction gearbox: BWD4).

● Control system: PLC control.

● Machine net weight: about 8 tons .

● Voltage: 380V/ 3phase/ 50 Hz.

● Dimensions of forming machine: Approx. L*W*H 7m*1m*1.4m (Frame welded with steel pipe)

● Forming roll material: Cr12MoV.

● Cutting mold material: Cr12MoV Heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● Equipped with a set of hydraulic system unit.

● With two sets of mold cut-off.

● Motor power 4 kW.

● Adopt cylinder control cut-off method.

● Adoption of non-stop cylinder jack cut-off method

Unloading

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

● Pneumatic automatic unloading is adopted.

PLC computer control box

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Automatic measurement: encoder

● Control the length and quantity with PLC. The machine automatically cuts the length and stops when the required quantity is reached.

● Length can be modified

● Control panel: push-button switches, touch screen

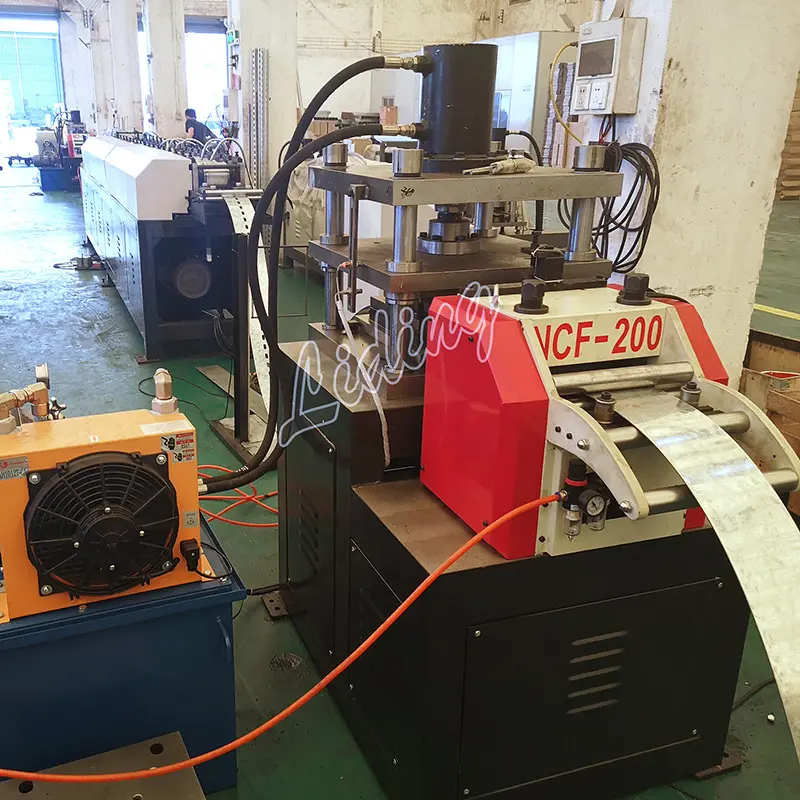

Product display

Company Feature

• Foshan Liding Technology Co.,ltd gives priority to customers and makes effort to provide them with quality services.

• It has been years since our company was built in With the experience and knowledge accumulated in these years, we regard the problem from the perspective of development, seek opportunities through challenges, and turn the crisis into a turning point. Through constant struggle and breakthrough, we have won a number of honors and have been highly recognized and trusted by the industry, the market and consumers.

• Good geographic location, excellent traffic conditions, and telecommunications make contribution to Foshan Liding Technology Co.,ltd's sustainable development.

Customers who need our products are welcomed to contact us for consultation.