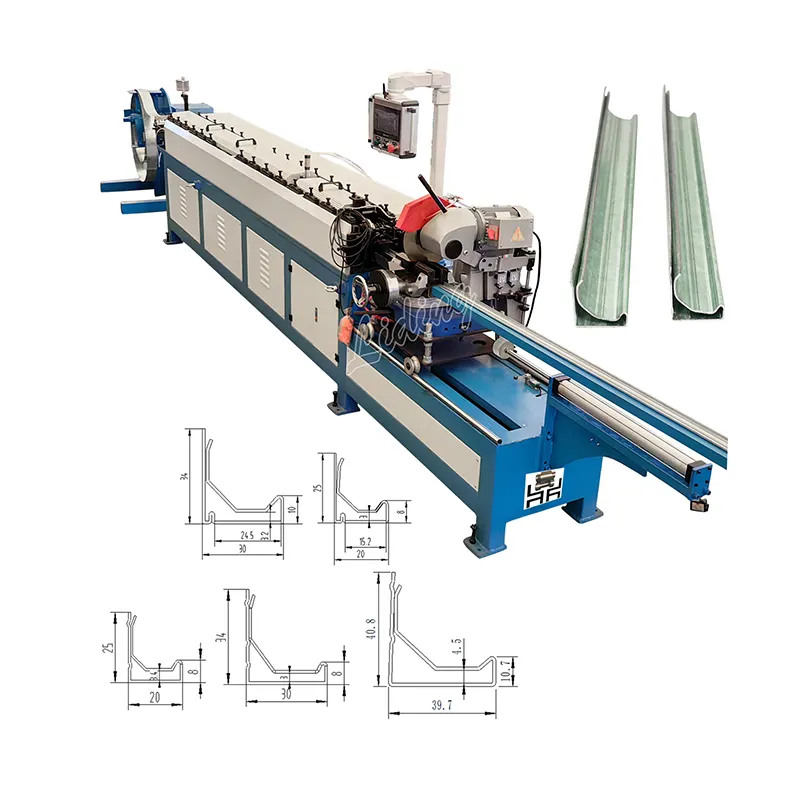

Good Selling Tdf Duct Machine Tdf Duct Machine Company

Product details of the tdf duct machine

Product Overview

As our workers conduct manufacturing by using the latest technologies, Liding Machine tdf duct machine is exquisite in every detail. This product conforms to the international industry quality standard. Multiple in function and wide in application, tdf duct machine can be used in many industries and fields. With the growing customer base, the production will be used more widely in the near future.

Product Description

In the production process of tdf duct machine, we carefully polish the details, so as to strive for perfect quality.

Main parameters

tdc flange forming machine details

① Feeding material: aluzinc/galvanized steel/colored steel coil or as customer request

② Feeding Thickness : 0.8-1.0mm

③ Productivity: 6-8m/min

④ hydraulic pump station power:2.2kw

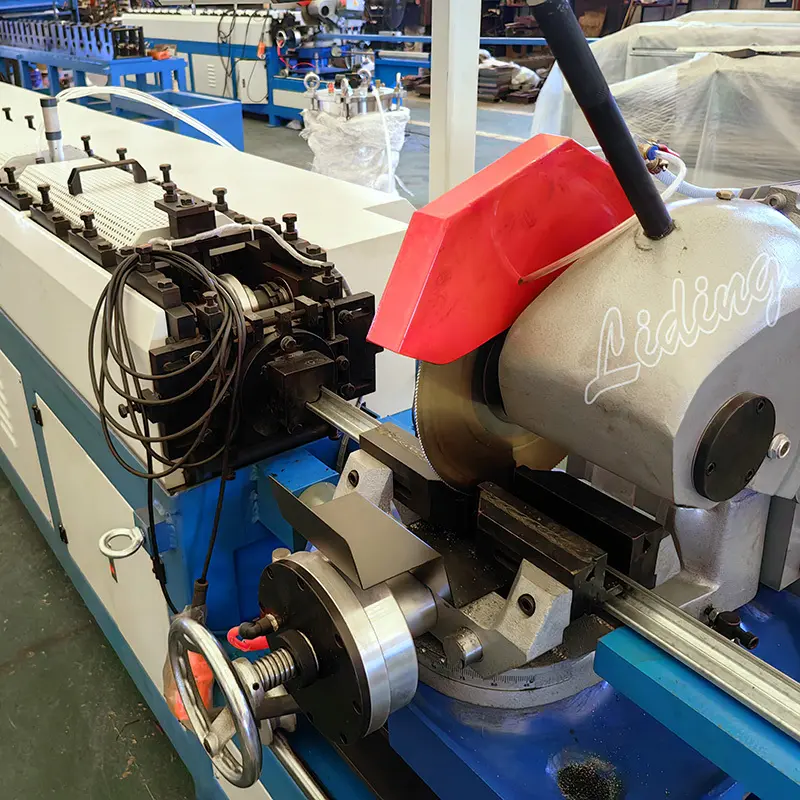

⑤ Cutting blade: heat treatment hardness HRC60°-62°

⑥ Forming machine size: approx. L*W*H 7m*0.8m*1.2m

⑦ Machine net weight: approx. 2.5 tons

⑧ Machine table:welded with 100*80 square tube

⑨ Side plate thickness:25mm

⑩ Main motor power:4kw

⑪ Rolling stages:15stages+ 5 rollers for straightening

⑫ Shaft diameter : ¢42mm

⑬ Shaft material:45# steel,quenched and finely ground outer circle

⑭ main bearing material :6207

⑮ Roller material: GCr15 steel

⑯ Control systerm: PLC control system with touch screen

⑰ Roller driven type:Chain and gear transmission

⑱ Voltage: 380V/ 3phase/ 50 Hz

Producing process

Decoiling → Feeding → Roll forming →Circular steel sawing-off →Run-out table

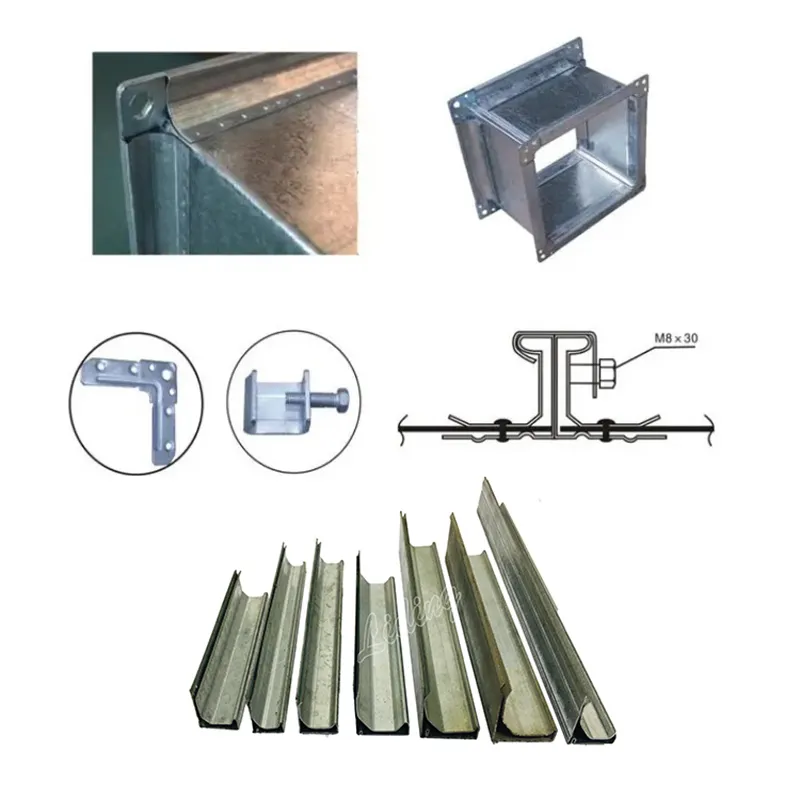

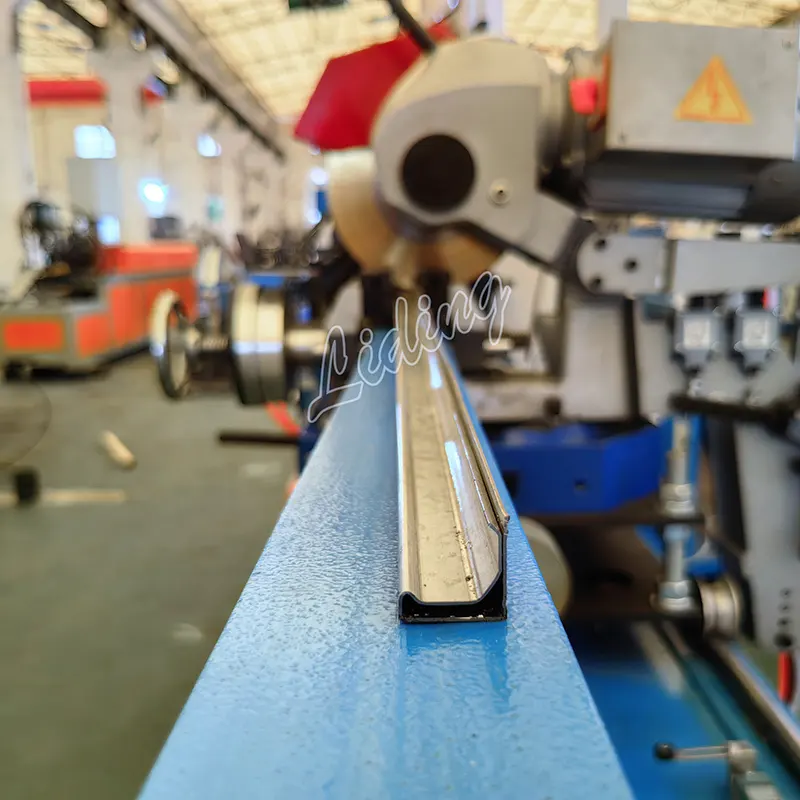

Product display

Company Introduction

佛山市立鼎科技有限公司 is a company in fo shan. Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines is one of our main products. With a focus on service, Foshan Liding Technology Co.,ltd provides comprehensive services for customers. Constantly improving service ability contributes to the sustainable development of our company. For bulk purchase of the products, please contact us.