Good Selling Cold Rolled Steel Machine Best Supplier for Factory

Product details of the cold rolled steel machine

Product Introduction

The production of Liding Machine cold rolled steel machine conforms with the norms and guidelines defined by the market. The additional functions of Liding Machine product deliver more economic benefits to customers. Under the premise of steady growth in domestic markets, 佛山市立鼎科技有限公司 has gradually expanded its foreign markets.

Composition of the machine

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 300mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

● with power transmission.

NC precision electronic CNC roller feeder

● Material width: 200mm

● Maximum material thickness: 2.0mm

● Servo motor:AC0.8KW

● Feeding speed: 15m/min

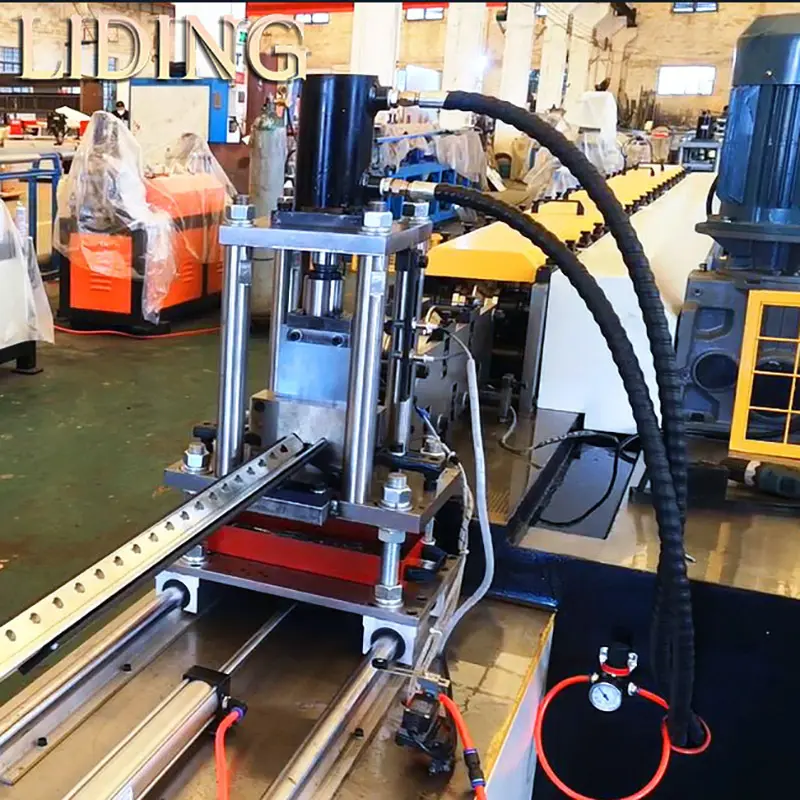

punching mold,2 set

● Width of material: unspecified

● Material thickness 1.5mm

● Mold Material Cr12MoV

● Hydraulic system:25-ton cylinder hydraulic station

Basic Configuration

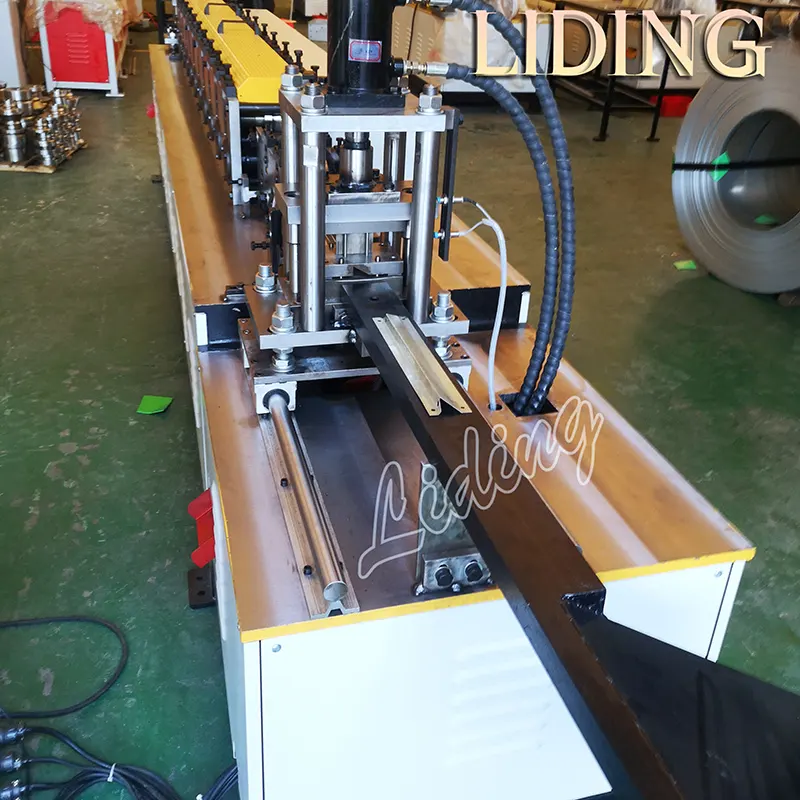

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 4kw

● Molding speed: 0-6m/min

● Number of molding groups: 8 groups

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 14m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● With a set of hydraulic system device

● With one set of cutting mold

● In-line fiber optic detection shutdown cut-off

PLC computer control cabinet

● Adopt Panasonic PLC, human-machine interface control, domestic frequency converter speed control.

● The main electrical parts are made of Schneider and Shihlin products.

● The length is measured by internal encoder

● The electric control box adopts fully sealed ventilation cooling device.

● The power supply of the control system adopts overload protection, and the electric control frame is connected with an aviation plug

● Cut off method with stop

● Voltage; 380V 50Hz

Workflow

Electric Decoiling & straightening - servo feeding - hydraulic punching round hole, punching square hole die, - cold roll forming - cutting - finished

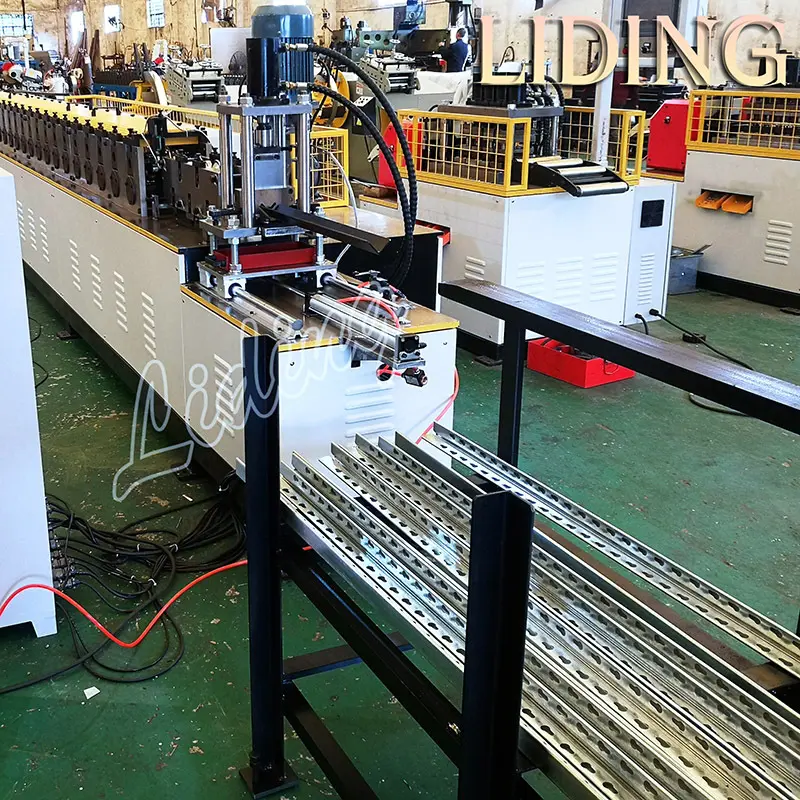

Product display

Company Feature

• Our company has established a professional talent team, so as to provide continuous driving force for our sustainable development. All our talents are industry elites from various fields in production and R&D, brand operation, sales promotion, and so on.

• Foshan Liding Technology Co.,ltd has a sales network covering the whole country. Some products are exported to America, Africa, Europe, and other countries and regions. Now we are an influential company in the industry.

• Foshan Liding Technology Co.,ltd constantly improves product quality and service system depending on technical advantages. Now we have a nationwide marketing service network.

• During years of development, Foshan Liding Technology Co.,ltd has been developing firmly to lead the trend of the industry. Now we are a leader in the industry.

Customers are sincerely welcome to visit Foshan Liding Technology Co.,ltd for business negotiation.