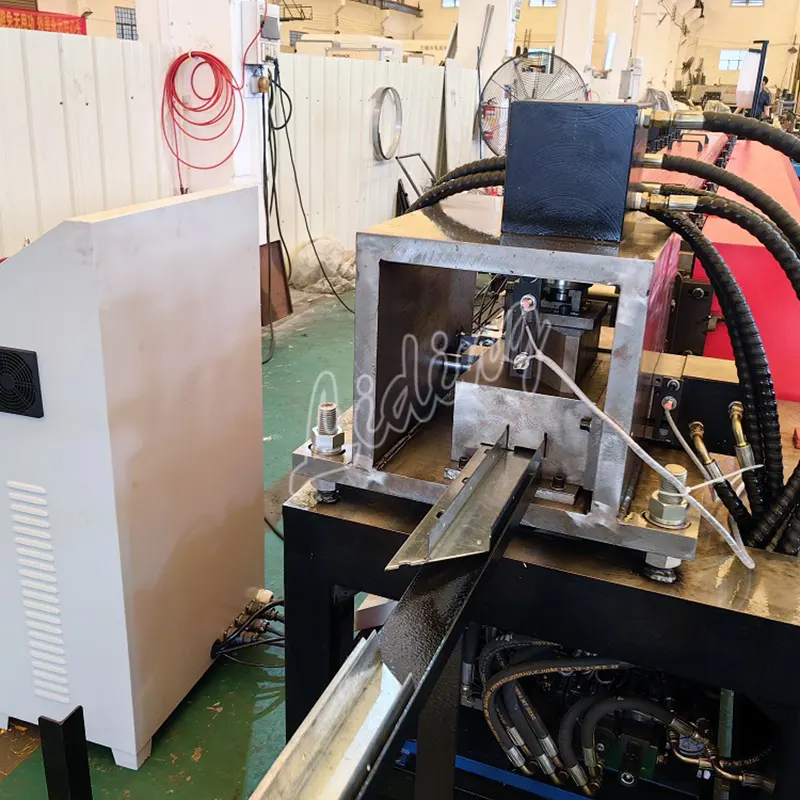

Factory Directcold Forming Machine Manufacturers for Sale

Profile

Workflow

Decoiling - Cold Roll Forming - Cutting - Finishing

Composition of the machine

● Decoiler,1 ton

● Forming machine,18 groups

● Hydraulic cut-off mold,3 set

● Run out table,1 set

● PLC control cabinet,1 set

Basic Configuration

I. Electric Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 1000kg

● Quantity: One.

● Manual Expansion

● No power transmission,with brakes.

II. Forming machine(5)

● Applicable materials:Galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 11kw

● Molding speed: 1-3m/min

● Number of molding groups: 18 groups+5 groups straightening

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 30mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 3 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 6m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

V. Cutting off parts(1)

● With a set of hydraulic system device

● Hydraulic motor 7.5KW, one station oil cylinder

● With 1 set of flange hole molds, 2 sets of spigot hole molds, 1 set of 45-degree cut-off molds

● Mold material: CR12MOV

● Processing hardness HRC60°-62°.

● Adopt online encoder to detect the stopping and cutting.

VI. Run out table

● Flat length 1 meters

● Flat table structure using square tube angle iron composition.

Basic Configuration

VII. PLC computer control cabinet(3)

● Voltage: 380 V, 50 Hz, 3Phase

● Panasonic PLC, human-machine interface control, domestic inverter speed control.

● Main electrical parts adopt Schneider and Shihlin products.

● The length of the encoder using the internal control encoder counting method

● Electronic control box adopts fully sealed ventilation cooling device.

● Control system power supply using overload protection, electronic control frame using aviation plug connection

● Stopping cut-off mode

Product display

Company Advantages

· Being made by advanced production techniques, Liding Machine cold forming machine manufacturers is delicate in appearance.

· The product has the advantages of good quality and excellent performance.

· Reliable quality can be seen in Liding Machine with its sophisticated design.

Company Features

· Owning the competence of manufacturing finest cold forming machine manufacturers, Liding Machine now has developed into a famous company which has won many reputation.

· We have a professional technical team. With years of experience and extensive technical expertise in the cold forming machine manufacturers industry, they are able to support customers throughout the whole product development phase.

· 佛山市立鼎科技有限公司 responds to customer needs, inspiring new product and service ideas. Ask!

Application of the Product

cold forming machine manufacturers is one of the main products of Foshan Liding Technology Co.,ltd. With wide application, our product can be applied to different industries and fields. And it is deeply loved and favored by customers.

We listen carefully to customer's requests and provide targeted solutions based on the bottleneck of customer. Therefore, we can help our customers to better solve problems.