Factory Direct Cold Roll Forming Machinery Price List

Composition of the machine

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 300mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

● with power transmission.

NC precision electronic CNC roller feeder

● Material width: 200mm

● Maximum material thickness: 2.0mm

● Servo motor:AC0.8KW

● Feeding speed: 15m/min

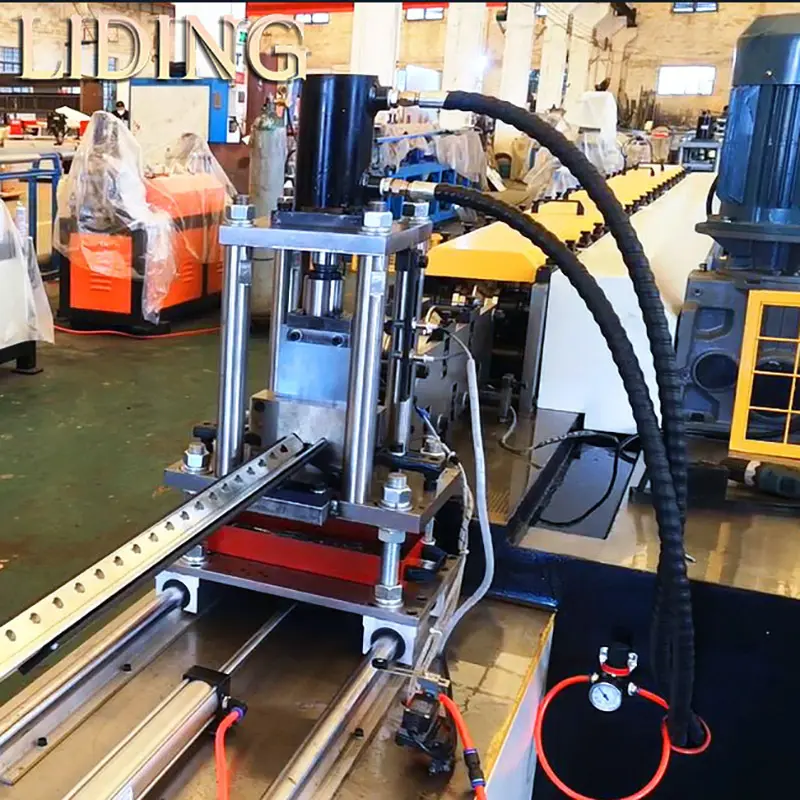

punching mold,2 set

● Width of material: unspecified

● Material thickness 1.5mm

● Mold Material Cr12MoV

● Hydraulic system:25-ton cylinder hydraulic station

Basic Configuration

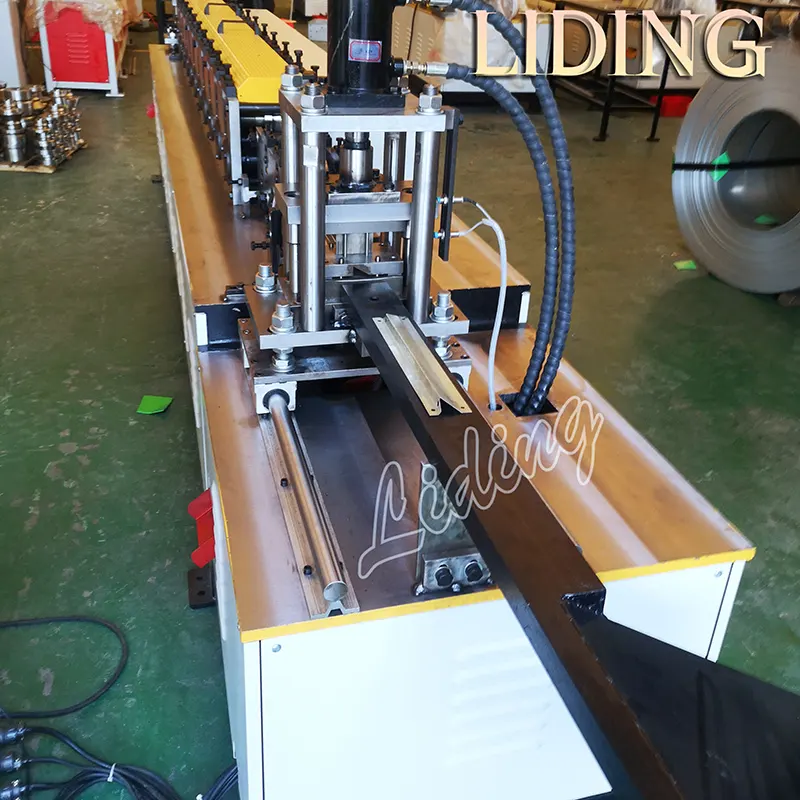

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 4kw

● Molding speed: 0-6m/min

● Number of molding groups: 8 groups

● Shaft diameter and material: ¢ 48mm, 45# steel

● Great wall type plywood: plate thickness 25mm

● Transmission: Chain & gear transmission.

● Control system: PLC control

● Machine net weight: about 4 tons

● Voltage: 380V/ 3phase/ 50 Hz

● Dimensions of molding machine: approx. L*W*H 14m*0.8m*1.2m

● Forming roll material: Cr12MoV

● Punching die, cutting die material: Cr12MoV heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● With a set of hydraulic system device

● With one set of cutting mold

● In-line fiber optic detection shutdown cut-off

PLC computer control cabinet

● Adopt Panasonic PLC, human-machine interface control, domestic frequency converter speed control.

● The main electrical parts are made of Schneider and Shihlin products.

● The length is measured by internal encoder

● The electric control box adopts fully sealed ventilation cooling device.

● The power supply of the control system adopts overload protection, and the electric control frame is connected with an aviation plug

● Cut off method with stop

● Voltage; 380V 50Hz

Workflow

Electric Decoiling & straightening - servo feeding - hydraulic punching round hole, punching square hole die, - cold roll forming - cutting - finished

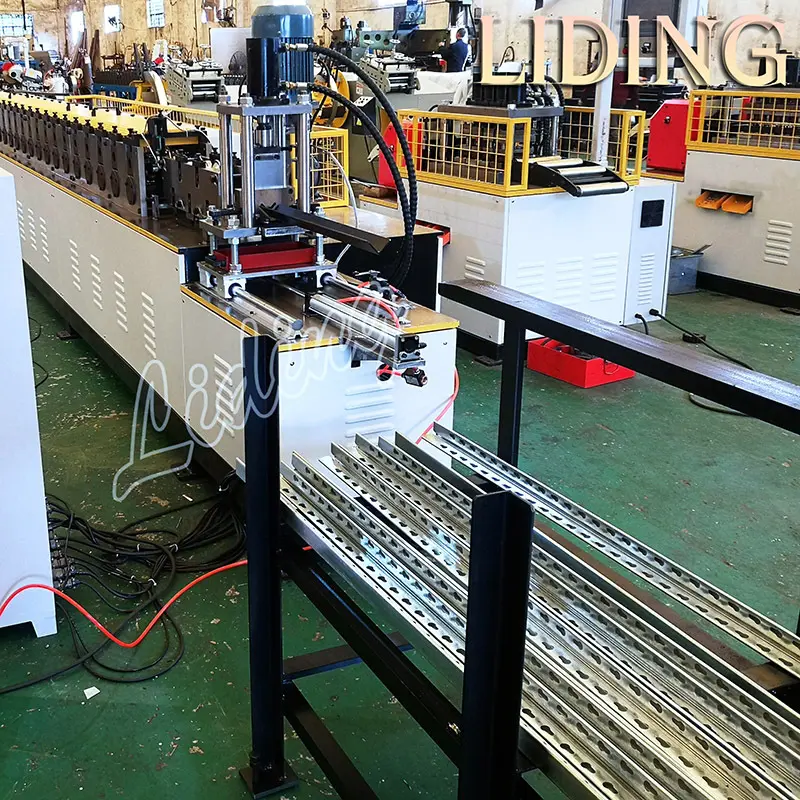

Product display

Company Advantages

· Liding Machine cold roll forming machinery undergoes regular inspection to achieve proper functionality.

· The stipulate strict quality inspection through the whole process guarantees the product is of the quality that meets the industry standard.

· With the new product developing technology, 佛山市立鼎科技有限公司 can shorten the development cycle of cold roll forming machinery and reduce costs.

Company Features

· Since the founding, 佛山市立鼎科技有限公司 has been engaged in designing, manufacturing, and supplying cold roll forming machinery. We have become an experienced manufacturer in the industry.

· 佛山市立鼎科技有限公司 has independent products researching and developing ability.

· 佛山市立鼎科技有限公司 intends to create a new brand for cold roll forming machinery and make a new market space. Welcome to visit our factory!

Application of the Product

Foshan Liding Technology Co.,ltd's cold roll forming machinery can be used in a variety of industries.

With a focus on Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines, Foshan Liding Technology Co.,ltd is dedicated to providing reasonable solutions for customers.