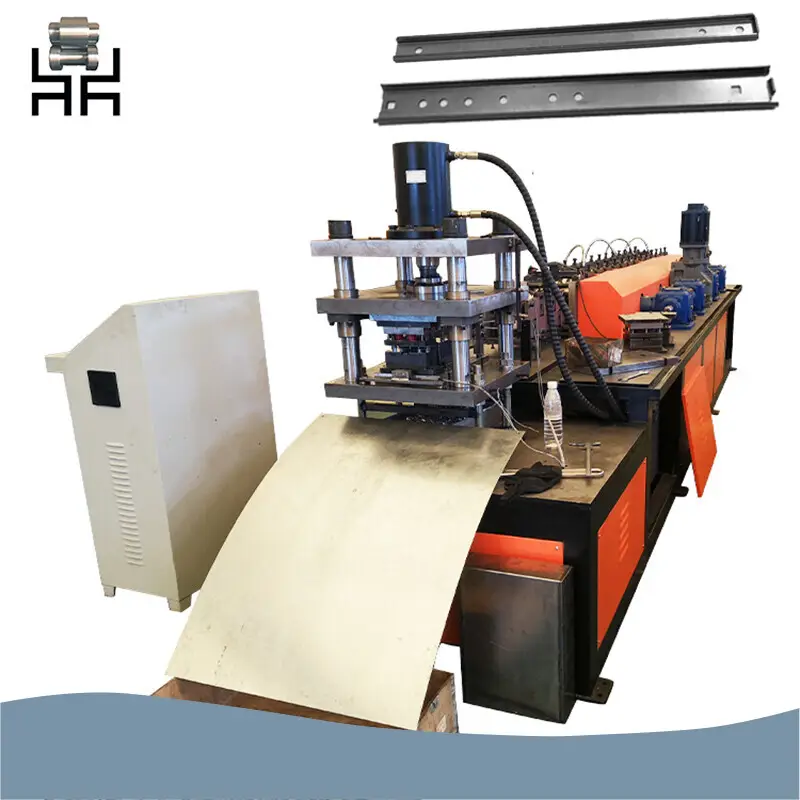

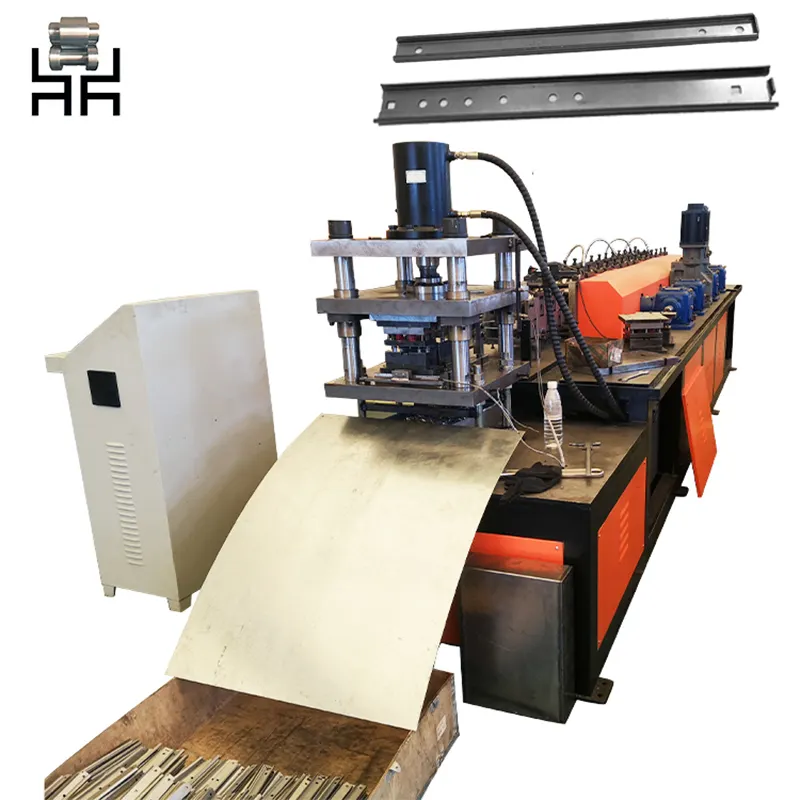

Customized Multi Station Cold Forging Machine Series for Factory

Composition of the machine

|

Configure |

Technical Parameters |

|

|

Manual Decoiler |

Load capacity 1 ton |

|

|

Roll forming machine |

Main Machine frame |

Side board is made of 45# 30mm steel plate |

|

Forming section |

12 groups rollers,Cr12mov steel, HRC up to 58~60º. |

|

|

Full Forming Section |

4 sets of main forming rolls for precision shaping |

|

|

Transmission section |

Reduction gearbox and gear transmission |

|

|

Punching and cutting section |

Composed of platform mold, stretching and cutting composite mold, single-cylinder hydraulic press and length measuring device. Punching material :DC53 |

|

|

Finished product collection box |

Used to take over the processed productions. |

|

|

Cooling circulation system |

The medium is emulsified oil |

|

|

Electric control system Security part |

Protection net, warning signs, manual emergency stop button,etc. |

|

Profile

Other type:Two-piece Guide Slide machine

Workflow

Decoiling - Cold Roll Forming - Hydraulic Punching & Cutting - Unloading - Finishing

Composition of the machine

● Manual Decoiler ,2 set

● Rail forming main machines (Internal and external ),2 set

● Hydraulic system Mold,2 set

● Electric control device (touch screen, inverter, PLC, etc.)

Composition of the machine

|

Item |

|

Technical Parameters |

|

Forming materials |

Material |

Cold Plate Material |

|

Material thickness |

1.5±0.02㎜ |

|

|

Inner diameter of the coil |

Ф460-Ф520 |

|

|

Processing capacity |

Main machine forming speed |

12pcs/min |

|

Processing length |

200-1000mm |

|

|

Processing Quality |

Dimensional accuracy |

±0.2㎜ when L≤500mm; |

|

Straightness; Disturbance; |

When L≤500mm, curvature not more than ±0.2㎜; |

|

|

Dimensional requirements of forming section |

According to the drawing |

|

|

Surface quality |

No obvious wrinkles, unevenness, surface galvanizing layer abrasion and other defects |

Product display

Company Advantages

· Liding Machine multi station cold forging machine is produced at a quick rate due to increased the efficiency of production.

· The product is rigorously tested on various parameters of quality to ensure high durability.

· To make sure its quality of multi station cold forging machine, we will strengthen inspection and check.

Company Features

· Since establishment, 佛山市立鼎科技有限公司 has begun to create competitive multi station cold forging machine.

· 佛山市立鼎科技有限公司 manufactures qualified products up to national and international standards.

· We will continue to serve our customers with a high degree of professionalism, maintaining and controlling all stages of the manufacturing process in accordance with China's cost and capability advantages while maintaining high-quality standards. Get an offer!

Application of the Product

The multi station cold forging machine produced by our company is widely used in various industries and fields.

Since the establishment, Foshan Liding Technology Co.,ltd has always been focusing on the R&D and production of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. With great production capability, we can provide customers with personalized solutions according to their needs.