Custom Cold Roll Forming Machinery Liding Machine

Product details of the cold roll forming machinery

Product Description

It is true that a fantastic design is a boon to the popularity of cold roll forming machinery. This product is tested on a set of norms prior to final delivery of the order. 佛山市立鼎科技有限公司 implements comprehensive quality inspection measures in all aspects of production.

Technical Parameters

|

Item |

Parameters |

|

Material |

Galvanized Plate |

|

Material Thickness |

1.8 - 2.0 MM (or 1.2 - 1.5 MM) |

|

Width of Coil |

According to Customer's Requirement |

|

Weight of Coil |

≤ 2000 KGS |

|

Blade Size |

150 – 205 MM |

|

Center Distance between Left and Right Grooves |

102 MM, Round Groove |

|

Formed Blade Width |

≤ 205 MM (If ﹥205 MM, Blade Flatness cannot be Guaranteed) |

|

Punching or Punch Blade Coverplate Hole |

According to Customer's Requirement |

|

Motor Power |

5.5 KW / 4 KW |

|

Forming Speed |

1 – 10M/Min, Adjustable |

|

Control Mode |

PLC Control |

|

Main Power Supply |

380 V, 50 HZ, 3 Phase |

|

Hydraulic System Pressure |

25 MPa, Working Pressure: 8 – 12 MPa |

|

External Dimensions of Line |

Approx. 5000 MM × 700 MM × 1200 MM (L × W × H) |

Main features

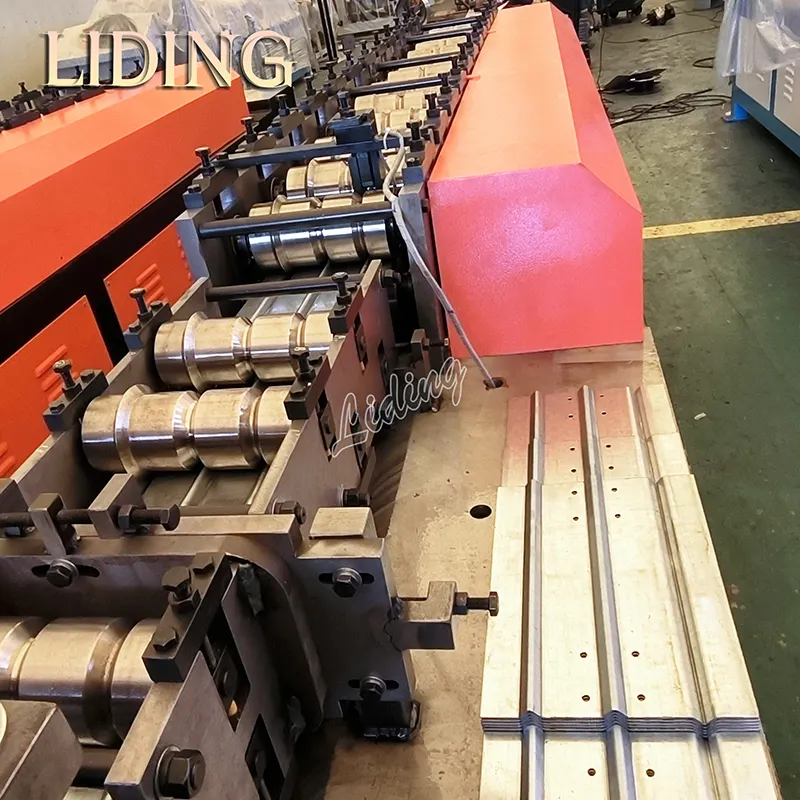

Fire Damper Blade Forming Machine is mainly composed of manual decoiler, forming machine, cutting & punching tools, electrical control system and hydraulic control system, widely used for the mass production of fire damper blade.

The whole line is controlled by Japanese Panasonic PLC, operator can set to run the line automatically and monitor the control process.

Workflow

Fire Damper Blade Machine Production Process:

Decoiling → Roll Forming → Straightening, Reshaping → Cutting To Length (Punching) → Manual Discharging.

Technical Parameters

|

Item |

Quantity |

|

Manual Decoiler |

1 Unit |

|

Forming Machine |

1 Unit |

|

Cutting, Punching Tools |

1 Set |

|

Electrical Control System |

1 Set |

|

Hydraulic Control System |

1 Set |

Product display

Company Advantage

• Our company has a professional and technical team, and regularly trains the team to improve their comprehensive strength. They can provide technical support for production and research and development of the products.

• The products of our company are favored by domestic and foreign customers.

• With the rapid development of economy, the customer service management no longer merely belongs to the core work of service-oriented enterprises. Instead, it has become the focus for all enterprises to be more competitive. In order to follow the trend of the times, our company has built an outstanding customer service management system by learning the advanced service idea and knowledge. We promote customers from satisfaction to loyalty through persisting in providing quality service.

• Foshan Liding Technology Co.,ltd started research and production of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines at its beginning in We also set up a research and development team. Now, we have achieved many effective results.

Hurry up! If you order Foshan Liding Technology Co.,ltd's leatherware now, you can enjoy discounts.