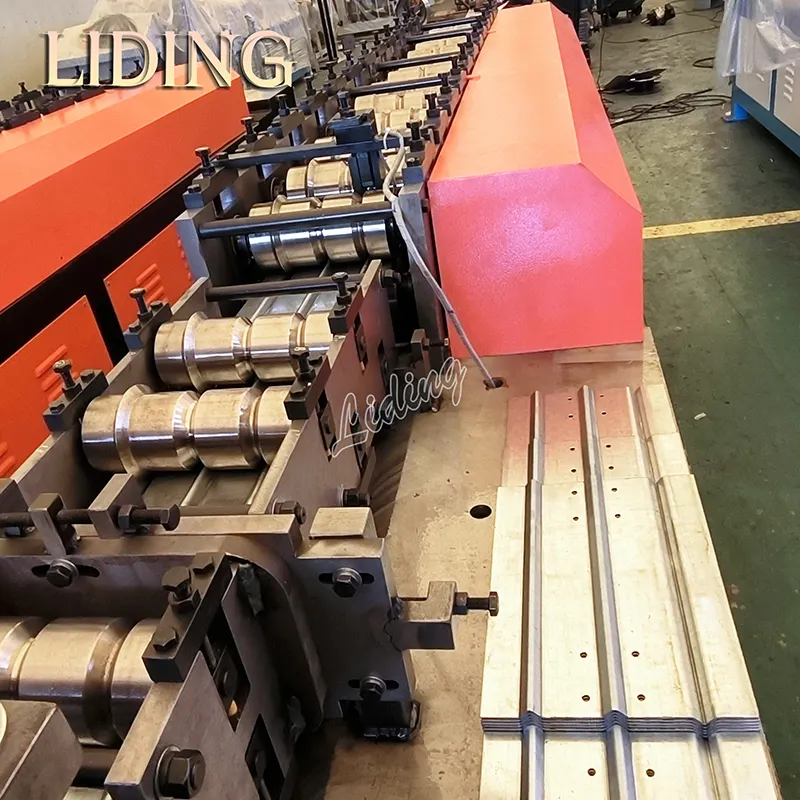

Cold Roll Machine Liding Machine Brand

Product details of the cold roll machine

Product Introduction

Liding Machine cold roll machine is accurately manufactured by using advanced machines, equipment, and tools. The product has a high cost performance for its strong functionality and high performance. 佛山市立鼎科技有限公司 is committed to transforming leading technologies into better and more competitive cold roll machine.

Technical Parameters

|

Item |

Parameters |

|

Material |

Galvanized Plate |

|

Material Thickness |

1.8 - 2.0 MM (or 1.2 - 1.5 MM) |

|

Width of Coil |

According to Customer's Requirement |

|

Weight of Coil |

≤ 2000 KGS |

|

Blade Size |

150 – 205 MM |

|

Center Distance between Left and Right Grooves |

102 MM, Round Groove |

|

Formed Blade Width |

≤ 205 MM (If ﹥205 MM, Blade Flatness cannot be Guaranteed) |

|

Punching or Punch Blade Coverplate Hole |

According to Customer's Requirement |

|

Motor Power |

5.5 KW / 4 KW |

|

Forming Speed |

1 – 10M/Min, Adjustable |

|

Control Mode |

PLC Control |

|

Main Power Supply |

380 V, 50 HZ, 3 Phase |

|

Hydraulic System Pressure |

25 MPa, Working Pressure: 8 – 12 MPa |

|

External Dimensions of Line |

Approx. 5000 MM × 700 MM × 1200 MM (L × W × H) |

Main features

Fire Damper Blade Forming Machine is mainly composed of manual decoiler, forming machine, cutting & punching tools, electrical control system and hydraulic control system, widely used for the mass production of fire damper blade.

The whole line is controlled by Japanese Panasonic PLC, operator can set to run the line automatically and monitor the control process.

Workflow

Fire Damper Blade Machine Production Process:

Decoiling → Roll Forming → Straightening, Reshaping → Cutting To Length (Punching) → Manual Discharging.

Technical Parameters

|

Item |

Quantity |

|

Manual Decoiler |

1 Unit |

|

Forming Machine |

1 Unit |

|

Cutting, Punching Tools |

1 Set |

|

Electrical Control System |

1 Set |

|

Hydraulic Control System |

1 Set |

Product display

Company Advantage

• Our company has a management team with modern operation idea. Meanwhile, we introduce a large number of experienced and skilled R&D talents. They both provide a strong foundation for manufacturing quality products.

• Our company was established in After years of hard work, we have accumulated a lot of industry experience. Moreover, we are highly recognized by the industry.

• There are multi main traffic lines passing through our company's location and the developed traffic network makes for the supplies distribution.

• Foshan Liding Technology Co.,ltd adheres to the principle of 'users are teachers, peers are examples'. We adopt scientific and advanced management methods and cultivates a professional and efficient service team to provide quality service for customers.

Foshan Liding Technology Co.,ltd sincerely looks forward to your presence, guidance, and partnership.