Bepoke Storage Rack Roll Forming Machine Storage Rack Roll Forming Machine Company

Company Advantages

· Liding Machine storage rack roll forming machine has a design that is prevalent in the industry.

· The product is under a strict and complete quality control system.

· The quality of customer service has been kept in each Liding Machine's staff 's mind.

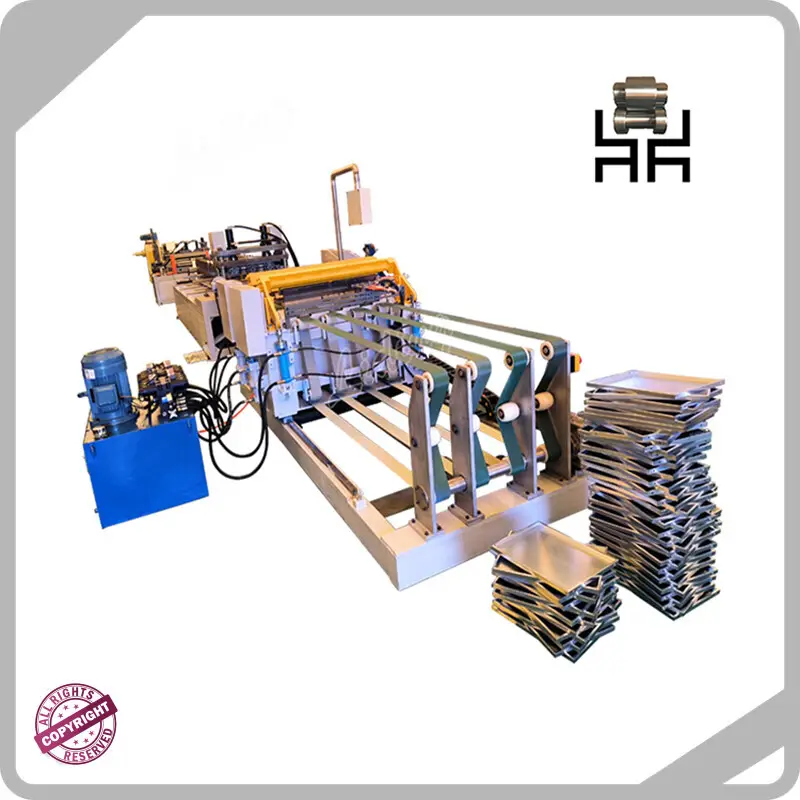

Composition of the machine

● Electric Decoiler,1 set

● Leveling Machine,1 set

● Feeding punching machine,1 set

● Roll rolling machine&Cutting mold,1 set

● Transition belt line,1 set

● Front and rear end bending machine,1 set

● Pneumatic system,1 set

● Electric control system,1 set

Basic Configuration

Electric Decoiler

● Max. width 600mm

● Motor power:3kw

● Maximum load capacity 5 tons

● Inner hole diameter 450*520mm

● Max. diameter 1300mm

Leveling machine

● Host structure: overall profile 100*80 steel plate welding

● Servo drive motor: 1.5KW servo motor

● Motor speed control: servo drive control

Feeding punching machine

● Length measurement control: closed loop feedback

● Roll material: 45# steel quenched, finely ground, chrome plated

● Roll diameter :φ75mmΧ600mm

● Die material: Cr12MOV

● Number of dies: 2 sets (2 sets of punching round holes and square ports)

● Number of cylinders: 2 7. Punching angle device type: hydraulic control

Basic Configuration

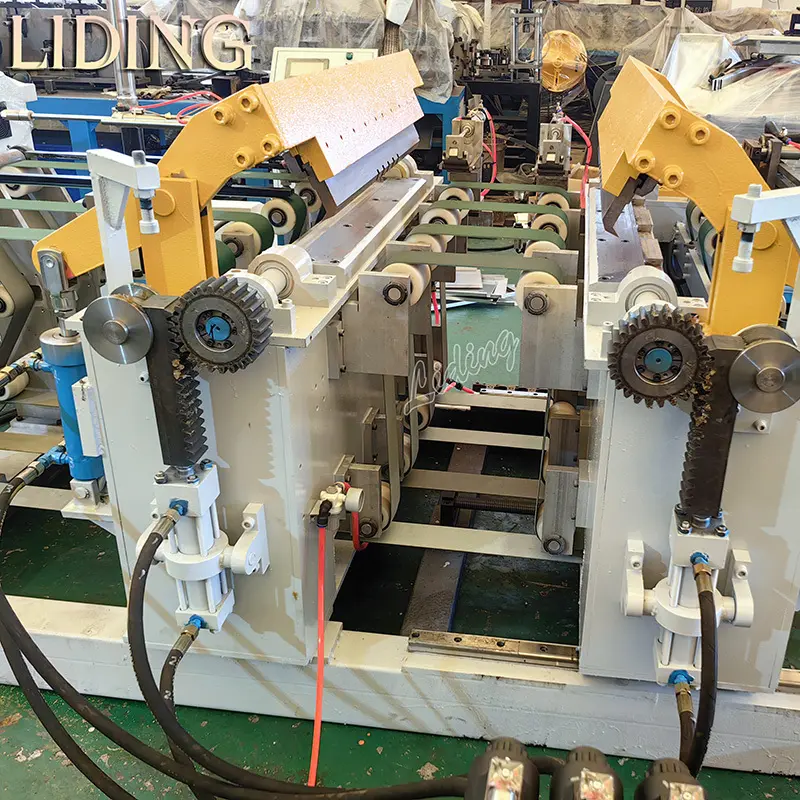

Forming machine

● Number of roller groups: 16 pairs of forming wheels

● Width is automatically adjusted by servo system

● Rolling wheel using GCr15 quenching up to HRC58-60

The front and rear end bending machine

● Machine consists of front and rear bending units, hydraulic system, conveying system, top material system, positioning system and machine body.

● Belt movement is driven by motor reducer

● Positioning system includes end positioning and side positioning and other parts.

Workflow

Decoiling → leveling and feeding→punching & servo feeding→Limit→Roll forming→Cut-off flanging→Front-end bending→Back-end bending

Profile

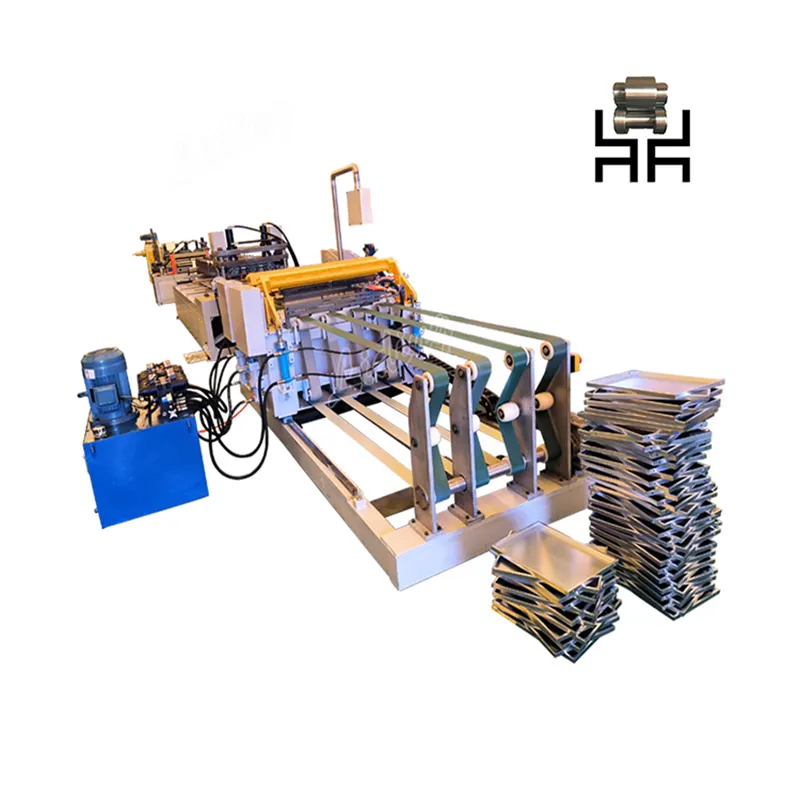

Product display

Company Features

· Based on outstanding ability in storage rack roll forming machine R&D and production, 佛山市立鼎科技有限公司 has got a good presence in the China market.

· Liding Machine employs advanced techniques to produce high quality storage rack roll forming machine. With the development of techniques, our high-end storage rack roll forming machine can achieve finest quality.

· 佛山市立鼎科技有限公司 now takes the lead in storage rack roll forming machine industry. Inquiry!

Product Details

Foshan Liding Technology Co.,ltd produces storage rack roll forming machine according to national standards, and the products are of good quality. The specific details are as follows.

Application of the Product

storage rack roll forming machine can be applied to different industries, fields and scenarios.

Since the establishment, Foshan Liding Technology Co.,ltd has always been focusing on the R&D and production of Air Duct flange Roll forming machine,Fire damper production line,HAVC Air duct line,C/U/Z purlin forming machine,Storage Shelf roll forming machines. With strong production strength, we can provide customers with personalized solutions according to customers' needs.

Product Comparison

Our storage rack roll forming machine has the following advantages over peer products.