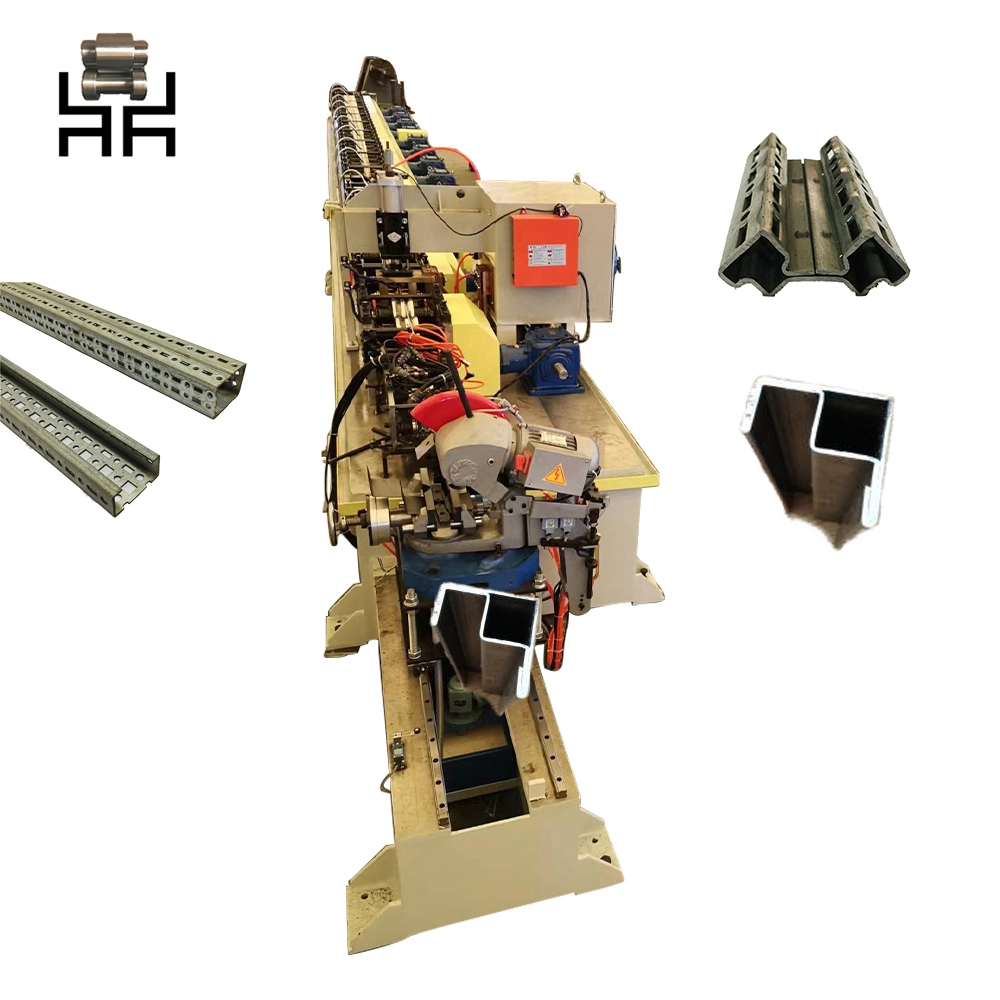

Sixteen-fold forming machine

Application:FOR Electric Cabinet

Electric Decoiler

Bore diameter 460~520mm.

Material width 200mm

Load weight 2000kg

Quantity: One.

Manual Expansion

with power transmission.

Application:FOR Electric Cabinet

Profile

Workflow

Electric decoiler→Servo feed→Punching→Material reversal→Cold roll forming→Rolling welding→Circular saw cutting→Cylinder pushes the finished product to the collection platform

Main parameters Composition of the machine

● Electric decoiler ,1 set

● Leveling machine ,1 set

● Servo feeder, 1 set

● 1 set of punching machine, 1 set of punching molds

● Material reversing rack,1 set

● 38+5 groups (including straightening) forming machine

● Roll welding machine,1 set

● Circular saw cutting device,1 set

● PLC control system, 1 set

Basic Configuration

Electric Decoiler

● Bore diameter 460~520mm.

● Material width 200mm

● Load weight 2000kg

● Quantity: One.

● Manual Expansion

● with power transmission.

Forming machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness: 1.5mm

● Main motor power: 11kw(2 set)

● Molding speed: 0-6m/min

● Number of molding groups: 38 groups+5 groups straightening

● Shaft diameter and material: ¢ 58mm, 45# steel

● Great wall type plywood: plate thickness 40mm

● Control system: PLC control

● Voltage: 380V/ 3phase/ 50 Hz

● Forming roll material: Cr12MoV

● Mechanical structure and transmission

Roller welding machinet

● Voltage power: 380V150KW

Circular saw blade cutting machine

● Motor 2.2KW

● Clamping, saw: pneumatic

● Saw blade diameter: 275mm

Run-out table

● Scale length 3000mm, cylinder to promote the finished product slant slide down to the collection platform

● Collecting platform width 600mm

PLC computer control cabinet

● Voltage: 380 V, 50 Hz, 3Phase

● Control the length and quantity with PLC. The machine automatically cuts the length and stops when the required quantity is reached.

● Length can modify

● Control panel: push-button switch, touch screen

Product display