Unveiling The Technology Behind Square Pipe Roll Forming Machines

Are you curious about how square pipe roll forming machines work? If so, you’re in the right place. In this article, we'll take a deep dive into the technology behind square pipe roll forming machines, uncovering the fascinating process that allows them to create perfectly shaped square pipes. Whether you're a seasoned professional in the industry or simply have an interest in the mechanics of machinery, this is a must-read for anyone looking to gain a better understanding of this innovative technology. So, let's dive in and unveil the intricate design and operation of square pipe roll forming machines.

- Understanding the Basics of Square Pipe Roll Forming Machines

Roll forming machines are an integral part of the manufacturing industry, and they play a crucial role in shaping and forming a variety of metal products. One specific type of roll forming machine that is widely used in the industry is the square pipe roll forming machine. In this article, we will delve into the technology behind square pipe roll forming machines, and provide an in-depth understanding of the basics of how they work.

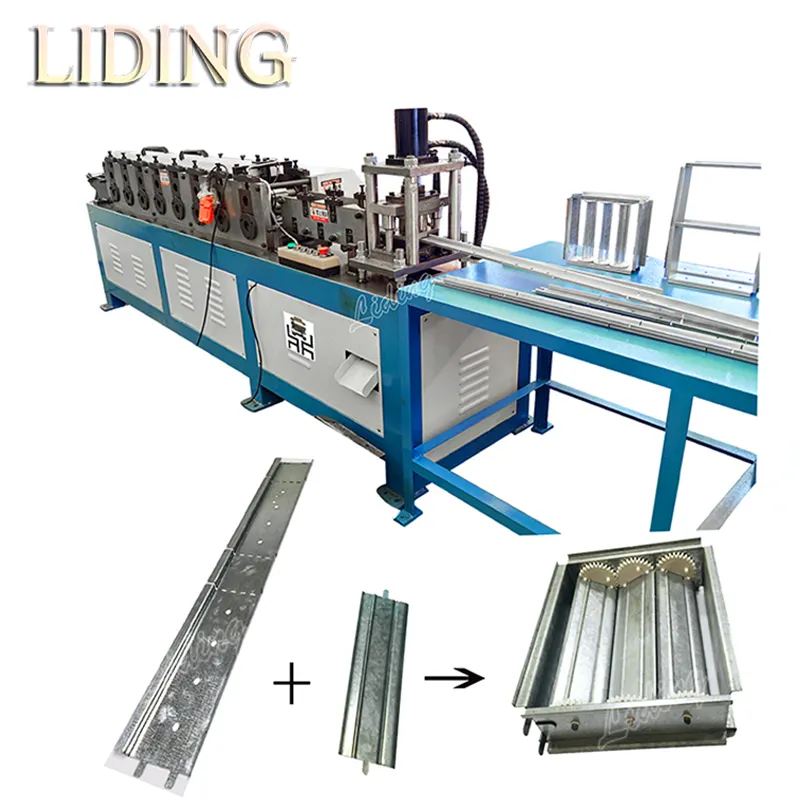

The square pipe roll forming machine is a specialized piece of equipment designed to produce square pipes with high precision and accuracy. It is a highly efficient and cost-effective solution for manufacturing square pipes of different sizes and thicknesses. The machine operates by passing a continuous strip of metal through a series of roll forming stands, where it is gradually shaped into the desired square pipe profile.

One of the key components of a square pipe roll forming machine is the set of roll forming stands. These stands are equipped with a series of rollers that are strategically positioned to gradually bend and form the metal strip into a square shape. The design and configuration of the rollers are crucial in determining the final dimensions and quality of the square pipe produced by the machine. Additionally, the roll forming stands are often adjustable, allowing for flexibility in producing square pipes of varying sizes and specifications.

The square pipe roll forming machine also features a range of other essential components such as decoilers, straightening units, cutting units, and control systems. The decoiler is responsible for feeding the metal strip into the machine, while the straightening unit ensures that the strip is properly aligned and free of any deformities. The cutting unit then trims the square pipe to the desired length, and the control system oversees the entire production process, ensuring that the machine operates efficiently and accurately.

In terms of operation, the square pipe roll forming machine follows a sequential process to produce square pipes. The metal strip is initially fed into the machine through the decoiler, and it passes through the straightening unit to ensure that it is flat and precise. The strip then enters the roll forming stands, where it undergoes a series of bending and forming operations to achieve the square shape. Finally, the cut-off unit trims the newly formed square pipe to the required length, completing the production process.

Square pipe roll forming machines are highly versatile and can be used to produce square pipes for a wide range of applications, including construction, automotive, furniture, and more. The ability to customize the dimensions, thickness, and material of the square pipes makes these machines highly adaptable to various manufacturing needs. Furthermore, the efficiency and accuracy of square pipe roll forming machines make them a cost-effective solution for mass production of square pipes.

In conclusion, the technology behind square pipe roll forming machines is a critical aspect of metal manufacturing. These machines are capable of producing high-quality square pipes with precision and efficiency, and they play a vital role in meeting the demands of various industries. Understanding the basics of how square pipe roll forming machines work is crucial for manufacturers looking to optimize their production processes and enhance their capabilities in metal forming.

- The Role of Advanced Technology in Improving Machine Efficiency

Unveiling the Technology Behind Square Pipe Roll Forming Machines - The Role of Advanced Technology in Improving Machine Efficiency

The manufacturing industry has always been at the forefront of technological advancements, and the roll forming industry is no exception. The use of advanced technology has greatly improved the efficiency and performance of square pipe roll forming machines, making them vital equipment for the production of various square pipes used in construction, automotive, and other industries.

One of the key factors that contributes to the improved efficiency of square pipe roll forming machines is the incorporation of advanced control systems. These systems use computer numerical control (CNC) technology to precisely control the movements of the machine, resulting in high accuracy and repeatability in the production of square pipes. With the use of CNC technology, manufacturers can produce square pipes with complex shapes and dimensions, meeting the diverse needs of their customers.

Furthermore, the integration of advanced sensors and monitoring systems in square pipe roll forming machines has significantly improved their performance and reliability. These sensors continuously monitor various parameters such as material thickness, pressure, and temperature, allowing the machine to make real-time adjustments to ensure consistent and high-quality output. This level of automation not only increases the efficiency of the production process but also minimizes the chances of errors and defects in the manufactured square pipes.

In addition to the advancements in control and monitoring systems, the use of advanced materials and coatings in the construction of square pipe roll forming machines has also contributed to their improved efficiency. The use of high-strength materials and advanced coatings not only increases the durability and longevity of the machine but also reduces the wear and tear on critical components, resulting in lower maintenance and downtime.

Moreover, the incorporation of advanced tooling and forming technologies in square pipe roll forming machines has enabled manufacturers to produce square pipes with higher precision and quality. Advanced tooling technologies, such as quick-change tooling systems and multi-step forming processes, allow for rapid setup and changeover, increasing the flexibility and adaptability of the machine to produce a wide range of square pipe profiles.

Furthermore, the use of advanced software and simulation tools has enabled manufacturers to optimize the design and operation of square pipe roll forming machines, leading to increased efficiency and productivity. These tools allow manufacturers to analyze and simulate various aspects of the roll forming process, such as material flow, tooling design, and forming parameters, to identify potential improvements and optimize the performance of the machine.

In conclusion, the role of advanced technology in improving machine efficiency is evident in the advancements made in square pipe roll forming machines. The integration of advanced control systems, sensors, monitoring systems, materials, tooling, and software has significantly enhanced the performance, reliability, and flexibility of these machines, making them indispensable for the production of high-quality square pipes. As technology continues to evolve, we can expect further improvements in the efficiency and capabilities of square pipe roll forming machines, driving the continued growth and innovation in the roll forming industry.

- Exploring the Components and Mechanisms of Square Pipe Roll Forming Machines

The square pipe roll forming machine is a key piece of equipment in the manufacturing industry, used for the production of square pipes of various sizes and specifications. This article aims to delve into the intricate components and mechanisms that make up these machines, providing a comprehensive understanding of their technology and functionality.

The primary components of a square pipe roll forming machine include the decoiler, feeding guide, roll forming system, cutting device, hydraulic system, and control system. Each of these components plays a crucial role in the seamless production of square pipes. The decoiler is responsible for holding the raw material, typically a coil of steel, and feeding it into the machine. The feeding guide ensures the proper alignment of the material as it enters the roll forming system, which consists of a series of rollers that gradually shape the material into a square pipe. The cutting device then precisely cuts the formed pipe to the desired length, while the hydraulic system provides the necessary power for the machine's operation. Lastly, the control system regulates the entire process, ensuring accuracy and consistency in the production of square pipes.

The roll forming system is the heart of the square pipe roll forming machine, consisting of several sets of rollers that gradually bend the raw material into the desired shape. These rollers are meticulously designed to create the specific dimensions and profiles of the square pipe, allowing for a high degree of precision in the manufacturing process. Additionally, the roll forming system can be adjusted to accommodate various sizes and thicknesses of materials, making the machine versatile and adaptable to different production requirements.

The cutting device of the square pipe roll forming machine is another critical component, as it determines the final length of the produced pipes. This device is equipped with a saw or blade that can cleanly and accurately cut through the formed pipe, ensuring uniformity and consistency in the finished products. Furthermore, the cutting device can be configured to make both straight and angled cuts, allowing for the creation of pipes with customized end profiles.

The hydraulic system of the square pipe roll forming machine provides the necessary power and pressure to drive the various components of the machine. This system utilizes hydraulic cylinders, pumps, and valves to control the movement of the rollers, cutting device, and other key parts of the machine. The hydraulic system plays a crucial role in ensuring the smooth and efficient operation of the square pipe roll forming machine, contributing to its overall reliability and performance.

In conclusion, the technology behind square pipe roll forming machines is a complex and intricate system of components and mechanisms that work together to produce high-quality square pipes. Understanding the intricacies of these machines is essential for manufacturers looking to utilize this technology in their production processes. By exploring the components and mechanisms of square pipe roll forming machines in detail, we can gain a deeper appreciation for the engineering and innovation that goes into their design and functionality.

- An Overview of the Latest Innovations in Square Pipe Roll Forming Technology

When it comes to manufacturing square pipe products, the roll forming process is an essential technology that has seen significant advancements in recent years. This article will provide an overview of the latest innovations in square pipe roll forming technology, aiming to shed light on the advancements that have revolutionized the manufacturing industry.

One of the key innovations in square pipe roll forming technology is the integration of advanced computer numerical control (CNC) systems. These systems allow for precise control of the production process, resulting in higher levels of accuracy and consistency in the final product. The use of CNC systems also enables manufacturers to create complex and intricate designs with ease, expanding the possibilities for square pipe products.

In addition to CNC systems, the latest square pipe roll forming machines also incorporate advanced material handling technology. This includes automated material loading and unloading systems, as well as in-line quality control measures. These advancements not only increase the efficiency of the production process but also ensure the overall quality of the square pipe products.

Furthermore, the latest innovations in square pipe roll forming technology also focus on enhancing the durability and longevity of the machines themselves. This includes the use of high-strength materials and advanced engineering techniques to build robust and reliable equipment. By investing in durable machinery, manufacturers can minimize downtime and maintenance costs, ultimately improving their overall productivity.

Another notable advancement in square pipe roll forming technology is the incorporation of energy-efficient features. With a growing emphasis on sustainability and environmental responsibility, manufacturers are increasingly looking for ways to reduce their energy consumption. The latest roll forming machines are designed to optimize energy usage, leading to cost savings and a reduced environmental impact.

Moreover, the integration of digital technology has also played a significant role in advancing square pipe roll forming technology. From real-time monitoring and data analytics to predictive maintenance capabilities, digital innovation has transformed the way manufacturers operate and maintain their equipment. This digital revolution has led to improved productivity, reduced downtime, and enhanced overall performance in the manufacturing process.

In conclusion, the latest innovations in square pipe roll forming technology have resulted in significant advancements in the manufacturing industry. From the integration of advanced CNC systems and material handling technology to the focus on durability, energy efficiency, and digitalization, the latest square pipe roll forming machines are setting new standards for precision, efficiency, and sustainability. As manufacturers continue to invest in these cutting-edge technologies, the future looks promising for the production of square pipe products.

- The Future of Square Pipe Roll Forming Machines: Trends and Developments

Unveiling the Technology Behind Square Pipe Roll Forming Machines: The Future of Square Pipe Roll Forming Machines: Trends and Developments

Square pipe roll forming machines are an indispensable tool in the manufacturing industry, and the technology behind them is constantly evolving. As the demand for square pipe products continues to rise, manufacturers are constantly looking for ways to improve their processes and stay ahead of the competition. In this article, we will explore the trends and developments shaping the future of square pipe roll forming machines.

One of the most significant trends in the industry is the adoption of advanced materials and technologies in the design and construction of square pipe roll forming machines. Manufacturers are increasingly turning to high-strength materials such as stainless steel and titanium to create machines that are more durable and capable of withstanding the rigorous demands of modern production environments. Additionally, the integration of cutting-edge technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) is enabling manufacturers to create machines with greater precision and efficiency.

Another important trend in the industry is the development of customizable and flexible square pipe roll forming machines. As the demand for custom-designed square pipe products continues to grow, manufacturers are under pressure to deliver machines that can accommodate a wide range of specifications and requirements. To meet this demand, manufacturers are increasingly designing machines that can be easily reconfigured and adapted to produce a variety of square pipe products without the need for extensive retooling or reprogramming.

In addition to advancements in materials and design, the future of square pipe roll forming machines is also being shaped by developments in automation and robotics. The integration of automated systems and robotics into the manufacturing process is enabling manufacturers to achieve higher levels of productivity and efficiency. This trend is particularly relevant in industries that require high-volume production of square pipe products, where the use of automation and robotics can significantly reduce labor costs and improve overall process reliability.

Furthermore, the future of square pipe roll forming machines is also being influenced by the growing demand for sustainable and environmentally friendly manufacturing practices. As the global focus on sustainability continues to increase, manufacturers are under pressure to develop machines that are more energy-efficient and produce less waste. In response to this demand, many manufacturers are investing in the development of square pipe roll forming machines that are designed to minimize energy consumption and reduce the environmental impact of the manufacturing process.

Overall, the future of square pipe roll forming machines is being shaped by a combination of advanced materials, customizable designs, automation, and sustainability. As the demand for square pipe products continues to rise, manufacturers are under pressure to deliver machines that are more efficient, flexible, and environmentally friendly. By embracing these trends and developments, manufacturers can stay ahead of the competition and meet the evolving needs of the market.

Conclusion

In conclusion, the technology behind square pipe roll forming machines plays a crucial role in the efficiency and precision of the manufacturing process. As a company with 9 years of experience in the industry, we understand the importance of staying up-to-date with the latest advancements in technology to deliver high-quality products to our customers. With our commitment to innovation and continuous improvement, we are dedicated to pushing the boundaries of what is possible in the field of square pipe roll forming machines. We are excited to see what the future holds for this technology and are eager to continue serving our customers with the best products possible. Thank you for joining us on this journey of unveiling the technology behind square pipe roll forming machines.