The Efficiency Of TDC Flange Forming Machine For Ductwork Fabrication

Are you looking to streamline your ductwork fabrication process and improve efficiency in your facility? Look no further! Our article explores the incredible efficiency and benefits of using a TDC flange forming machine for ductwork fabrication. Discover how this state-of-the-art technology can revolutionize your production process and lead to significant time and cost savings. Read on to uncover the advantages of integrating TDC flange forming machine into your operation.

- Introduction to TDC Flange Forming Machine

In the world of ductwork fabrication, efficiency is key. The ability to quickly and accurately form flanges on ductwork can make a significant impact on the overall productivity and profitability of a fabrication shop. This is where the TDC (Transverse Duct Connector) Flange Forming Machine comes into play. In this article, we will discuss the introduction and efficiency of the TDC Flange Forming Machine, and how it has revolutionized the ductwork fabrication process.

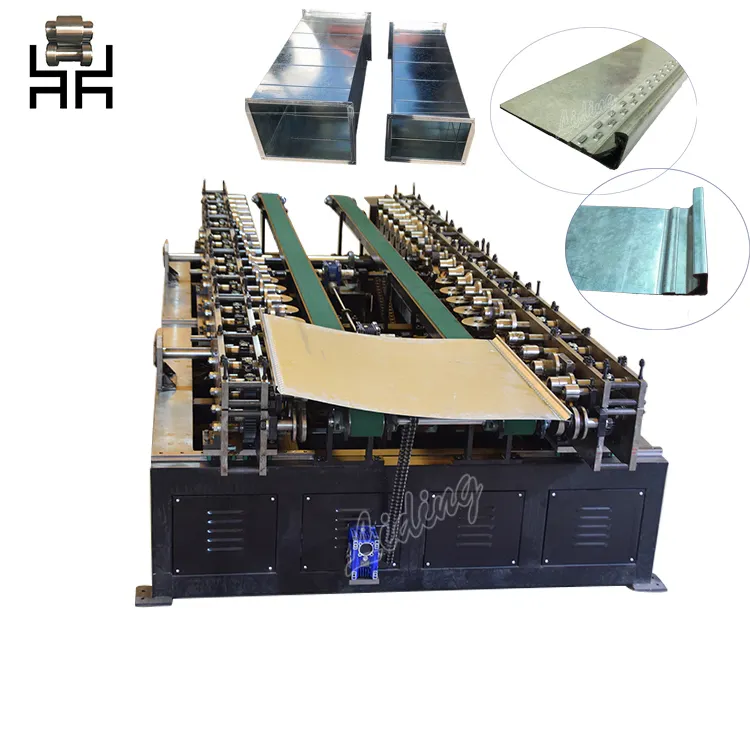

The TDC Flange Forming Machine is a specialized piece of equipment designed to create the flanges used in ductwork construction. The TDC flange is a type of flange connection system commonly used in the HVAC industry for joining duct segments together. This machine streamlines the process, allowing for fast and precise flange forming, which ultimately leads to increased efficiency and improved end-product quality.

One of the key features of the TDC Flange Forming Machine is its ability to form flanges quickly and consistently. This machine is equipped with the latest technology and precision engineering, allowing for the creation of perfectly formed TDC flanges with minimal effort. The speed and accuracy of the TDC Flange Forming Machine drastically reduce the time and labor required for flange formation, ultimately increasing the productivity of the fabrication shop.

Furthermore, the TDC Flange Forming Machine is designed to be user-friendly, making it easy for operators to set up and operate. The intuitive controls and ergonomic design of the machine ensure that even novice operators can quickly learn how to use it effectively. This user-friendly aspect helps to minimize training time and allows for seamless integration into the fabrication process.

In addition to its speed and ease of use, the TDC Flange Forming Machine also produces consistently high-quality flanges. The precision engineering of the machine ensures that each flange is formed to exact specifications, resulting in a perfect fit when assembling ductwork. This level of accuracy reduces the need for rework and adjustments, saving both time and materials in the fabrication process.

The efficiency of the TDC Flange Forming Machine extends beyond just the flange forming process. By streamlining this critical step in ductwork fabrication, the machine allows for faster overall production. This means that fabrication shops can take on more projects and meet tight deadlines with ease, ultimately increasing their profitability.

In conclusion, the introduction of the TDC Flange Forming Machine has revolutionized the ductwork fabrication process. Its speed, precision, user-friendly design, and overall efficiency have made it an invaluable tool for fabrication shops looking to maximize productivity and profitability. As the demand for high-quality ductwork continues to grow, the TDC Flange Forming Machine will undoubtedly play a vital role in meeting and exceeding the expectations of the industry.

- Benefits of TDC Flange Forming Machine for Ductwork Fabrication

When it comes to ductwork fabrication, it is essential to have the right tools and equipment to ensure efficiency and precision. One such tool that has become increasingly popular in the industry is the TDC (Transverse Duct Connector) flange forming machine. This innovative machine has revolutionized the way ductwork is fabricated, providing a wide range of benefits that have made it a staple in the fabrication process.

One of the key benefits of using a TDC flange forming machine for ductwork fabrication is its efficiency. The machine is designed to streamline the process of forming TDC flanges, which are a vital component of ductwork assembly. With its automated operation, the TDC flange forming machine can produce consistent and precise flanges in a fraction of the time it would take with traditional methods. This not only increases productivity but also reduces labor costs, making it a highly cost-effective solution for ductwork fabrication.

In addition to its efficiency, the TDC flange forming machine also offers a high level of precision. The machine is equipped with advanced technology and precise measurement systems that ensure the accurate formation of TDC flanges. This level of precision is crucial in ductwork fabrication, as even minor discrepancies in flange dimensions can compromise the integrity and functionality of the duct system. By utilizing a TDC flange forming machine, fabricators can rest assured that their flanges will meet the necessary specifications and standards.

Furthermore, the TDC flange forming machine is incredibly versatile, capable of accommodating a wide range of duct sizes and materials. Whether working with galvanized steel, stainless steel, aluminum, or other materials, the machine can effectively form TDC flanges with consistent quality. This versatility enables fabricators to tackle a variety of ductwork projects without the need for multiple machines or extensive retooling, further streamlining the fabrication process.

Another significant benefit of using a TDC flange forming machine is the reduction of material waste. Traditional methods of forming TDC flanges often result in significant material waste due to imprecise cuts and measurements. However, the advanced technology and precision of the TDC flange forming machine minimize material waste, ultimately saving fabricators time and money while promoting sustainability in the fabrication process.

In conclusion, the TDC flange forming machine has proven to be a game-changer in the world of ductwork fabrication. Its efficiency, precision, versatility, and waste-reduction capabilities make it an invaluable asset for fabricators looking to enhance their operations. By embracing this innovative technology, fabricators can elevate the quality of their ductwork while increasing productivity and cost-effectiveness. As the demand for high-quality ductwork continues to rise, the TDC flange forming machine stands as a testament to the power of innovation in the industry of fabrication.

- Efficiency and Speed of TDC Flange Forming Machine

The Efficiency of TDC Flange Forming Machine for Ductwork Fabrication - Efficiency and Speed of TDC Flange Forming Machine

In the field of ductwork fabrication, the efficiency and speed of TDC flange forming machines have revolutionized the way in which ductwork is produced. These machines have become an integral part of the process, allowing for quick and accurate forming of TDC flanges, which are essential for connecting ductwork and ensuring a secure and airtight seal. In this article, we will explore the efficiency and speed of TDC flange forming machines and their impact on ductwork fabrication.

One of the key factors that sets TDC flange forming machines apart from traditional methods is their efficiency. These machines are designed to streamline the forming process, reducing production times and increasing overall productivity. By automating the forming of TDC flanges, these machines eliminate the need for manual labor, significantly reducing the time and effort required to produce ductwork. This efficiency not only saves time but also reduces labor costs, making TDC flange forming machines a cost-effective solution for ductwork fabrication.

Furthermore, the speed at which TDC flange forming machines operate is impressive. These machines are capable of quickly and accurately forming TDC flanges, allowing for high-volume production without sacrificing quality. This speed is essential for meeting tight deadlines and fulfilling large orders, making TDC flange forming machines an invaluable asset for ductwork manufacturers and fabricators.

The efficiency and speed of TDC flange forming machines are further enhanced by their precision and accuracy. These machines are equipped with advanced technology and tooling, allowing for precise forming of TDC flanges with minimal error. This precision ensures that each flange is formed to the exact specifications required, resulting in consistent and high-quality ductwork. This level of accuracy is essential for ensuring that ductwork meets industry standards and regulations, further highlighting the importance of TDC flange forming machines in ductwork fabrication.

Additionally, the efficiency and speed of TDC flange forming machines have a direct impact on overall production capacity. By streamlining the forming process and increasing production speed, these machines allow for a higher output of ductwork, meeting the demands of a rapidly growing industry. This increased production capacity not only allows for larger orders to be fulfilled but also enables ductwork manufacturers to take on more projects and expand their business.

In conclusion, the efficiency and speed of TDC flange forming machines have transformed the way in which ductwork is fabricated. These machines offer a level of efficiency and speed that is unparalleled by traditional forming methods, allowing for quick and accurate production of TDC flanges. Their precision, accuracy, and impact on production capacity make TDC flange forming machines an essential tool for ductwork fabrication, providing a cost-effective and high-quality solution for manufacturers and fabricators.

With their ability to streamline the forming process, reduce production times, increase productivity, and ensure precision and accuracy, TDC flange forming machines have become a cornerstone of efficient and effective ductwork fabrication. As the industry continues to evolve, the role of these machines will only become more prominent, further solidifying their importance in the production of high-quality ductwork.

- Quality and Precision of Ductwork Fabrication with TDC Flange Forming Machine

When it comes to ductwork fabrication, quality and precision are of utmost importance. The use of TDC (Transverse Duct Connection) flange forming machine has revolutionized the way ductwork is fabricated, providing efficient and precise results that meet the highest industry standards.

The TDC flange forming machine is a powerful tool that is utilized in the manufacturing of air duct systems. It is designed to produce TDC flanges, which are acclaimed for their high-quality, air-tight seal, and ease of assembly. The machine utilizes cutting-edge technology to ensure that the flanges are formed with incredible accuracy and consistency, resulting in ductwork that is free from leaks and defects.

One of the key benefits of using a TDC flange forming machine is its ability to streamline the fabrication process. By automating the formation of TDC flanges, the machine significantly reduces the time and labor required to produce ductwork, leading to increased efficiency and productivity. This not only saves on production costs but also allows for faster turnaround times, enabling manufacturers to meet tight project deadlines with ease.

Furthermore, the TDC flange forming machine is renowned for its ability to produce TDC flanges with exceptional precision. The machine is equipped with advanced controls and mechanisms that ensure each flange is formed to exact specifications, ensuring consistency and uniformity throughout the entire ductwork system. This level of precision is crucial in ensuring that the ductwork fits together seamlessly, minimizing air leakage and optimizing the overall performance of the HVAC system.

In addition to its efficiency and precision, the TDC flange forming machine is also lauded for its versatility. It is capable of forming TDC flanges from a variety of materials, including galvanized steel, stainless steel, and aluminum. This allows manufacturers to tailor the ductwork to specific project requirements, whether it be for commercial, industrial, or residential applications.

Another advantage of the TDC flange forming machine is its reliability. The machine is engineered for durability and can withstand the rigors of continuous use, delivering consistent results over the long term. This reliability ensures that manufacturers can depend on the machine to meet their production demands without compromise.

In conclusion, the TDC flange forming machine has proven to be an invaluable asset in the field of ductwork fabrication. Its ability to deliver quality and precision, combined with its efficiency, versatility, and reliability, makes it an essential tool for manufacturers seeking to produce high-performance ductwork systems. As the demand for superior air duct systems continues to grow, the TDC flange forming machine stands as a testament to the advancement of manufacturing technology in meeting these demands.

- Conclusion: The Impact of TDC Flange Forming Machine on Ductwork Fabrication Industry

The ductwork fabrication industry has seen a significant impact with the introduction of TDC (Transverse Duct Connection) flange forming machines. These machines have revolutionized the way ductwork is fabricated, offering increased efficiency and precision in the manufacturing process. In this article, we will explore the implications of TDC flange forming machines on the ductwork fabrication industry and the benefits they bring to the table.

One of the key advantages of TDC flange forming machines is their ability to streamline the fabrication process. By automating the flange forming process, these machines significantly reduce the time and labor required to produce ductwork. This not only leads to increased productivity but also allows for a faster turnaround on custom orders, ultimately benefiting both manufacturers and their clients. Additionally, the precision and consistency of TDC flange forming machines ensure that each piece of ductwork is of the highest quality, leading to fewer errors and rework.

Moreover, TDC flange forming machines also contribute to a reduction in material waste. The precise nature of these machines means that they can produce flanges with minimal scrap material, saving both time and resources. This not only aligns with an industry-wide trend towards sustainability but also has the potential to reduce costs for manufacturers in the long run.

Furthermore, the impact of TDC flange forming machines extends beyond the manufacturing process. These machines have also been found to improve the overall safety and ergonomics of ductwork fabrication. With the automation of the flange forming process, workers are less exposed to potentially hazardous tasks, reducing the risk of workplace injuries. Additionally, the increased efficiency of TDC flange forming machines means that workers can focus on more skilled aspects of fabrication, ultimately leading to a higher quality end product.

In conclusion, the introduction of TDC flange forming machines has significantly impacted the ductwork fabrication industry. From increased efficiency and precision to reduced material waste and improvements in safety, these machines have brought about a positive change in the way ductwork is manufactured. As the industry continues to evolve, it is clear that TDC flange forming machines will play a crucial role in shaping the future of ductwork fabrication.

Conclusion

In conclusion, the TDC flange forming machine has proven to be a highly efficient and reliable tool for ductwork fabrication. Its precision and speed make it a valuable asset for companies in the HVAC industry. With 9 years of experience in the field, we at [Your Company Name] have seen firsthand the impact this machine has had on our production processes. As technology continues to advance, we look forward to integrating more innovative solutions like the TDC flange forming machine into our operations, further enhancing our efficiency and productivity. As we continue to grow and adapt to the changing demands of the industry, we are confident that this machine will play a key role in our success.