The Ultimate Guide To Steel Roll Forming Machines: How They Work And Why You Need One

Welcome to our comprehensive guide on steel roll forming machines! Whether you're a seasoned professional or a novice, this article will provide you with all the information you need to understand the inner workings of steel roll forming machines and why they are essential for various industries.

Steel roll forming machines are vital pieces of equipment in the manufacturing industry, particularly in the production of metal parts and components. They play a crucial role in shaping and forming steel into various desired shapes and profiles, making them integral to the production process.

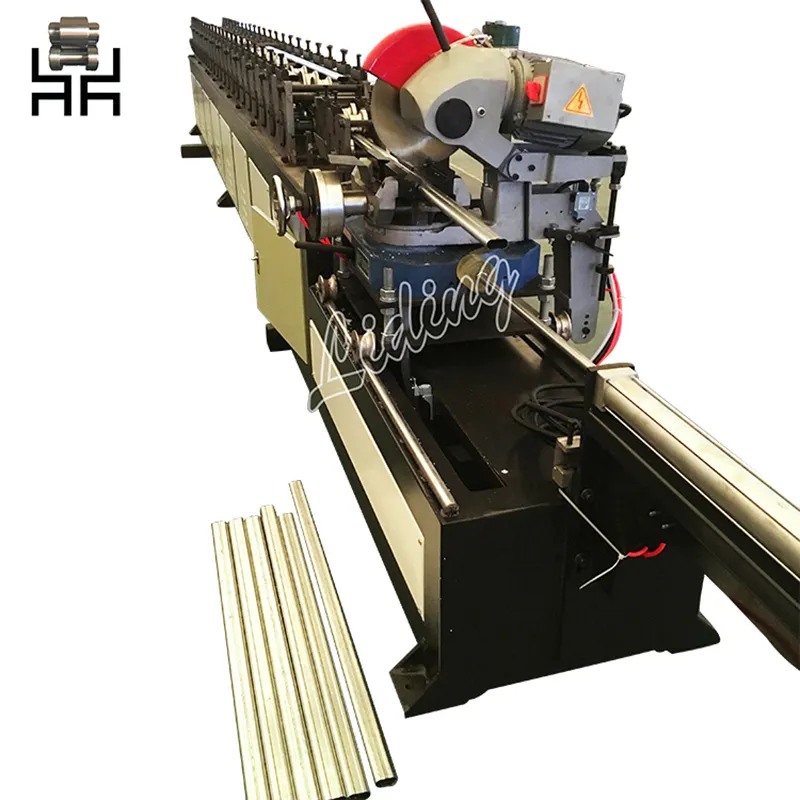

At Foshan Liding Technology Co., Ltd, we specialize in producing high-quality steel roll forming machines that are designed to meet the diverse needs of our clients in various industries.

A steel roll forming machine is used to shape and form metal, specifically steel, into a desired profile or shape. This process involves passing a continuous strip of metal through a series of roll stands, each with a different set of rollers that gradually bend and shape the metal into the desired form.

The steel roll forming process begins with the feeding of a continuous strip of metal, typically steel, into the roll forming machine. The metal strip passes through a series of roll stands, each equipped with a set of rollers that gradually shape and form the metal into the desired profile.

Steel roll forming machines offer a wide range of benefits, including high precision and accuracy, cost-effective production, versatility, and customization. They are essential for any manufacturing business looking to improve their production processes and increase productivity.

When selecting a steel roll forming machine, it is crucial to consider factors such as the specific requirements of your production process, the level of automation and customization offered by the machine, the quality and reliability of the machine, as well as the after-sales support and technical assistance provided by the manufacturer.

Steel roll forming machines are commonly utilized in industries such as construction, automotive manufacturing, appliance and furniture production, and solar energy. They are essential for creating uniform shapes and profiles from steel coils, contributing to the efficiency and cost-effectiveness of various manufacturing processes.

Proper maintenance and care are essential for ensuring the optimal performance and longevity of your steel roll forming machine. Regular inspections, cleaning, and lubrication are key to ensuring that your machine remains in top condition.

In conclusion, steel roll forming machines are essential for any company in the metal fabrication industry. If you're looking to revolutionize your manufacturing capabilities, investing in a high-quality steel roll forming machine is a worthwhile decision. With our comprehensive guide, you now have all the information you need to make an informed decision about incorporating this technology into your operations.