The Ultimate Guide To Shutter Roll Forming Machines: Everything You Need To Know

Welcome to the complete guide to shutter roll forming machines! If you're in search of a comprehensive resource that covers all aspects of these manufacturing marvels, you've come to the right place. From the fundamentals of roll forming to the intricacies of shutter production, this guide will equip you with the knowledge and insight you need to understand and make the most out of these machines. Whether you're a seasoned professional or a newcomer to the industry, this guide will arm you with the information you need to succeed. Let's delve into the fascinating world of shutter roll forming machines together!

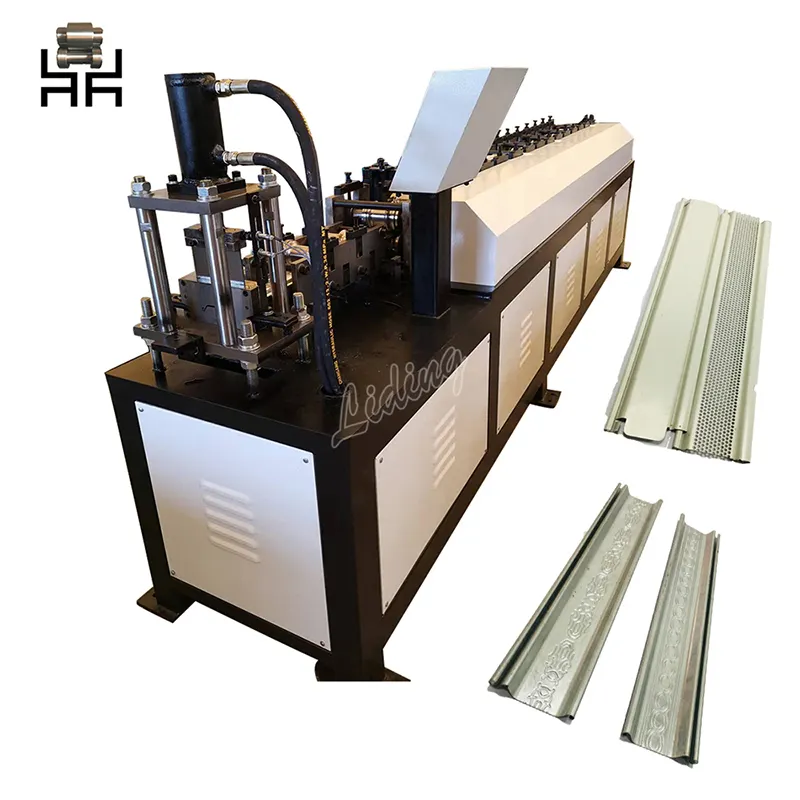

Understanding the Basics of Shutter Roll Forming Machines

Shutter roll forming machines are indispensable equipment in the production of shutters for various applications such as windows, doors, and security systems. In this guide, we'll take a comprehensive look at the basics of shutter roll forming machines, their functions, and the key factors to consider when selecting the right machine for your production needs.

At Foshan Liding Technology Co., Ltd, we specialize in manufacturing high-quality shutter roll forming machines under our brand name Liding Machine. With years of experience and expertise in the industry, we understand the importance of precision, efficiency, and reliability in roll forming technology.

Understanding the basics of shutter roll forming machines starts with knowing their primary function. These machines are designed to efficiently and accurately fabricate long lengths of metal into uniform, complex shapes required for producing shutters. The process involves feeding a metal coil through a series of rollers that gradually shape the metal into the desired profile. This continuous forming process ensures consistent quality and high productivity.

When selecting a shutter roll forming machine, it's crucial to consider various factors to ensure it meets your production requirements. At Liding Machine, we prioritize the following key aspects in our machines:

1. Material Compatibility: Our shutter roll forming machines are designed to handle a variety of materials, including aluminum, steel, and other metals commonly used in shutter production. The machines are equipped with adjustable tooling and settings to accommodate different material thicknesses and specifications.

2. Profile Flexibility: Our machines are capable of producing a wide range of shutter profiles, from standard designs to custom shapes, with quick changeover capabilities for efficient production.

3. Precision and Accuracy: Our machines are built with advanced leveler and straightening systems, digital controls, and high-precision tooling to achieve unmatched accuracy in forming shutters.

4. Production Capacity: Whether you're a small-scale manufacturer or a large production facility, our shutter roll forming machines are available in different configurations to meet various production capacities. We offer single-sided and double-sided machines with customizable speed and automation options to optimize output.

Apart from these essential factors, our machines are also equipped with advanced safety features, user-friendly controls, and ergonomic designs for operator convenience and safety.

In conclusion, understanding the basics of shutter roll forming machines is crucial in making informed decisions for your production needs. At Foshan Liding Technology Co., Ltd, we are committed to providing top-quality machines that deliver exceptional performance, reliability, and value for our customers in the shutter manufacturing industry. Contact us today to learn more about our Liding Machine products and how they can elevate your production capabilities.

Types and Variations of Shutter Roll Forming Machines

Shutter roll forming machines are vital equipment in the manufacturing of various types of shutters for doors and windows. They play a crucial role in shaping metal strips into the desired profile, ensuring efficiency and precision in the manufacturing process. As a leading manufacturer in the industry, Foshan Liding Technology Co., Ltd provides a wide range of shutter roll forming machines, each catering to different types and variations of shutters.

Types of Shutter Roll Forming Machines:

1. Manual Shutter Roll Forming Machines: These machines are operated manually, making them suitable for small-scale production or custom projects. The operator feeds the metal strips into the machine and manually adjusts the settings to form the required profiles.

2. Semi-Automatic Shutter Roll Forming Machines: Semi-automatic machines offer a balance between manual and fully automatic operation. They reduce the need for manual adjustments and can handle higher production volumes compared to manual machines.

3. Fully Automatic Shutter Roll Forming Machines: Fully automatic machines are capable of handling large-scale production with minimal human intervention. They are equipped with advanced control systems, which allow for precise and efficient forming of metal strips into shutter profiles.

Variations of Shutter Roll Forming Machines:

1. Single-sided Shutter Roll Forming Machines: These machines are designed to form shutter profiles on a single side of the metal strip. They are suitable for producing basic shutter designs and are more affordable compared to double-sided machines.

2. Double-sided Shutter Roll Forming Machines: Double-sided machines are capable of forming profiles on both sides of the metal strip simultaneously, allowing for the production of more complex and intricate shutter designs. They are ideal for high-volume production and versatile in creating different shutter styles.

3. Customizable Shutter Roll Forming Machines: Foshan Liding Technology Co., Ltd also offers customizable options for shutter roll forming machines, allowing customers to tailor the machines to their specific production needs. This includes customizing the number of forming stations, material handling systems, and control systems.

Key Features of Liding Shutter Roll Forming Machines:

- High-Quality Material: Our shutter roll forming machines are built using premium quality materials, ensuring durability and longevity in the production environment.

- Advanced Technology: Our machines are equipped with state-of-the-art technology, including precision forming rollers, PLC control systems, and automatic material feeding, ensuring high efficiency and accuracy in the forming process.

- Customization Options: We offer a range of customization options to meet the specific requirements of our customers, allowing for flexibility and adaptability in the production of different types and variations of shutters.

- Expert Support: Our team of experienced engineers and technicians are dedicated to providing expert support and guidance throughout the machine selection, installation, and operation process.

In conclusion, the selection of the right type and variation of shutter roll forming machine is essential for meeting the diverse production needs of shutters in the doors and windows industry. Foshan Liding Technology Co., Ltd offers a comprehensive range of high-quality and customizable shutter roll forming machines, equipped with advanced technology and backed by expert support, ensuring efficient and precise production of various types and variations of shutters.

Factors to Consider When Choosing a Shutter Roll Forming Machine

Shutter roll forming machines are indispensable equipment for the production of high-quality shutters used in various applications such as windows, doors, and cabinets. When choosing a shutter roll forming machine, there are several factors to consider to ensure that you are investing in the right equipment for your specific needs. In this article, we will discuss the key factors to consider when choosing a shutter roll forming machine, and provide an overview of our brand, Liding Machine, offered by Foshan Liding Technology Co., Ltd.

1. Quality and Efficiency

One of the most important factors to consider when choosing a shutter roll forming machine is the quality and efficiency of the equipment. Liding Machine offers a range of high-quality roll forming machines that are designed to provide efficient and reliable production of shutter components. Our machines are built with precision engineering and advanced technology to ensure smooth and consistent operation, resulting in high-quality shutters with minimal waste and downtime.

2. Customization and Flexibility

When choosing a shutter roll forming machine, it is crucial to consider the level of customization and flexibility it offers. Liding Machine provides a range of customizable options to meet the specific requirements of different shutter designs and materials. Our machines are designed to accommodate various metal thicknesses, profiles, and sizes, allowing for seamless customization and flexibility in production.

3. Durability and Longevity

Investing in a shutter roll forming machine is a significant decision, and it is essential to choose a machine that is durable and built to last. Liding Machine is committed to providing durable and long-lasting equipment that is built to withstand the rigors of high-volume production. Our machines are constructed with high-quality materials and components, ensuring longevity and reliability for years to come.

4. Support and Service

Another critical factor to consider when choosing a shutter roll forming machine is the level of support and service provided by the manufacturer. Liding Machine offers comprehensive support and service to ensure that our customers receive the necessary assistance and technical expertise. Our team of experienced professionals is dedicated to providing ongoing support, maintenance, and training to maximize the performance and efficiency of our machines.

5. Cost-Effectiveness

Finally, cost-effectiveness is an essential consideration when choosing a shutter roll forming machine. Liding Machine offers competitive pricing and cost-effective solutions for our range of roll forming machines. Our machines are designed to optimize production processes, reduce material waste, and increase overall efficiency, resulting in a cost-effective investment for our customers.

In conclusion, when choosing a shutter roll forming machine, it is crucial to consider the quality, customization, durability, support, and cost-effectiveness of the equipment. Liding Machine is a trusted provider of high-quality and reliable roll forming machines that are designed to meet the specific needs of shutter production. With our commitment to quality, customization, durability, support, and cost-effectiveness, Liding Machine is the ultimate choice for all your shutter roll forming needs.

Best Practices for Operating a Shutter Roll Forming Machine

Shutter roll forming machines have revolutionized the production of shutters, offering an efficient and cost-effective way to manufacture high-quality products. As a leading provider of shutter roll forming machines, Liding Machine (Foshan Liding Technology Co., Ltd) has compiled the ultimate guide to help operators understand the best practices for operating this innovative equipment.

Setting up and operating a shutter roll forming machine requires attention to detail and adherence to strict guidelines to ensure optimal performance and product quality. Here are the key best practices for operating a shutter roll forming machine.

Proper Machine Setup:

Before starting the production process, it is essential to ensure that the shutter roll forming machine is set up correctly. This includes checking the alignment of rollers, ensuring all safety guards are in place, and verifying that the machine is properly lubricated. Any deviation from the specified setup can result in subpar product quality and potential safety risks.

Material Handling:

The quality of the raw materials used in the production process significantly impacts the final product. Operators need to pay close attention to material handling, including the loading and feeding of the material into the machine. Proper material handling practices help prevent damage to the equipment and ensure consistent product quality.

Maintenance and Cleaning:

Regular maintenance and cleaning are essential for the smooth operation of a shutter roll forming machine. Liding Machine recommends implementing a comprehensive maintenance schedule to keep the machine in optimal condition. This includes checking and replacing worn-out components, cleaning the machine regularly, and addressing any issues promptly to prevent downtime.

Quality Control:

Consistent product quality is paramount in the manufacturing process. Liding Machine emphasizes the importance of implementing robust quality control measures throughout production. This includes periodic inspection of the products, monitoring the machine's performance, and making necessary adjustments to maintain quality standards.

Safety Measures:

Operating a shutter roll forming machine requires strict adherence to safety protocols. Liding Machine emphasizes the significance of providing comprehensive training to machine operators on safety procedures and guidelines. Regular safety audits and adherence to safety standards are crucial for preventing accidents and ensuring a safe working environment.

Utilizing Advanced Technology:

Liding Machine's shutter roll forming machines are equipped with advanced technology to streamline the production process and enhance efficiency. Operators are encouraged to leverage the machine's features to maximize productivity and minimize waste. Familiarizing themselves with the machine's capabilities ensures optimal performance and output.

Efficient Workflow Management:

Effective workflow management is essential for maximizing the productivity of a shutter roll forming machine. Liding Machine recommends establishing efficient production schedules, optimizing material flow, and minimizing downtime to achieve the highest possible output.

In conclusion, operating a shutter roll forming machine requires a comprehensive understanding of best practices and adherence to strict guidelines. By following Liding Machine's recommendations for proper machine setup, material handling, maintenance, quality control, safety measures, utilization of advanced technology, and efficient workflow management, operators can ensure the smooth and efficient operation of the equipment. Liding Machine remains committed to providing comprehensive support and guidance to operators for the successful operation of their shutter roll forming machines.

Maintenance and Troubleshooting Tips for Shutter Roll Forming Machines

Shutter roll forming machines are essential equipment for the manufacturing of shutters, which are commonly used in homes, offices, and commercial buildings. These machines are intricate pieces of equipment that require regular maintenance and troubleshooting to ensure optimal performance and longevity. In this article, we will provide you with a comprehensive guide to shutter roll forming machines, including everything you need to know about their maintenance and troubleshooting.

At Foshan Liding Technology Co., Ltd, we specialize in the design and production of high-quality shutter roll forming machines. Our Liding Machine brand is renowned for its precision engineering and reliable performance. Our machines are designed to meet the demanding requirements of the shutter manufacturing industry, and we are committed to providing our customers with the knowledge and support they need to keep their equipment running at its best.

Maintenance is a crucial aspect of keeping shutter roll forming machines in top condition. Regular maintenance tasks include cleaning the machine, lubricating moving parts, and inspecting for any signs of wear or damage. It is important to follow the manufacturer's guidelines for maintenance and to schedule regular maintenance appointments to ensure that the machine continues to operate efficiently.

In addition to regular maintenance, troubleshooting is also an important aspect of maintaining a shutter roll forming machine. Troubleshooting tasks may include identifying and addressing any issues with the machine's components, such as the roll forming rollers, cutting blades, or hydraulic systems. It is essential to have a thorough understanding of the machine's components and operation in order to effectively troubleshoot any issues that may arise.

One common issue with shutter roll forming machines is misalignment of the rollers, which can result in poor quality shutter profiles. To troubleshoot this issue, it is important to carefully inspect the rollers for any signs of damage or wear, and to ensure that they are properly aligned. Additionally, checking the hydraulic systems and adjusting the pressure as necessary can help to improve the quality of the formed shutters.

Another common problem with shutter roll forming machines is the buildup of debris and materials in the machine's components, which can cause blockages and impede the machine's performance. Regular cleaning and inspection of the machine's components can help to prevent these issues and ensure that the machine continues to operate smoothly.

In conclusion, shutter roll forming machines are complex pieces of equipment that require regular maintenance and troubleshooting to ensure optimal performance. At Foshan Liding Technology Co., Ltd, we are dedicated to providing our customers with the knowledge and support they need to keep their machines operating at their best. By following the maintenance and troubleshooting tips outlined in this article, you can ensure that your shutter roll forming machine continues to produce high-quality shutters for years to come.