The Efficiency Of An Automated Duct Production Line: Streamlining Manufacturing Processes

Looking to Revolutionize Your Manufacturing Processes with an Automated Duct Production Line?

In today's fast-paced manufacturing industry, companies are constantly seeking ways to improve efficiency and streamline production processes. One such innovation that has been gaining popularity is the automated duct production line. This advanced technology has revolutionized the way ducts are manufactured, offering a wide range of benefits that have a significant impact on the overall manufacturing process. In this article, we will explore the efficiency of an automated duct production line and how it can help you save time and resources while delivering high-quality products. Join us as we delve into the benefits of automation and how it can revolutionize your manufacturing operations.

In today’s fast-paced manufacturing industry, companies are constantly looking for ways to improve efficiency and streamline production processes. One way to achieve these goals is by streamlining manufacturing processes, and the use of an automated duct production line can provide numerous advantages in this regard.

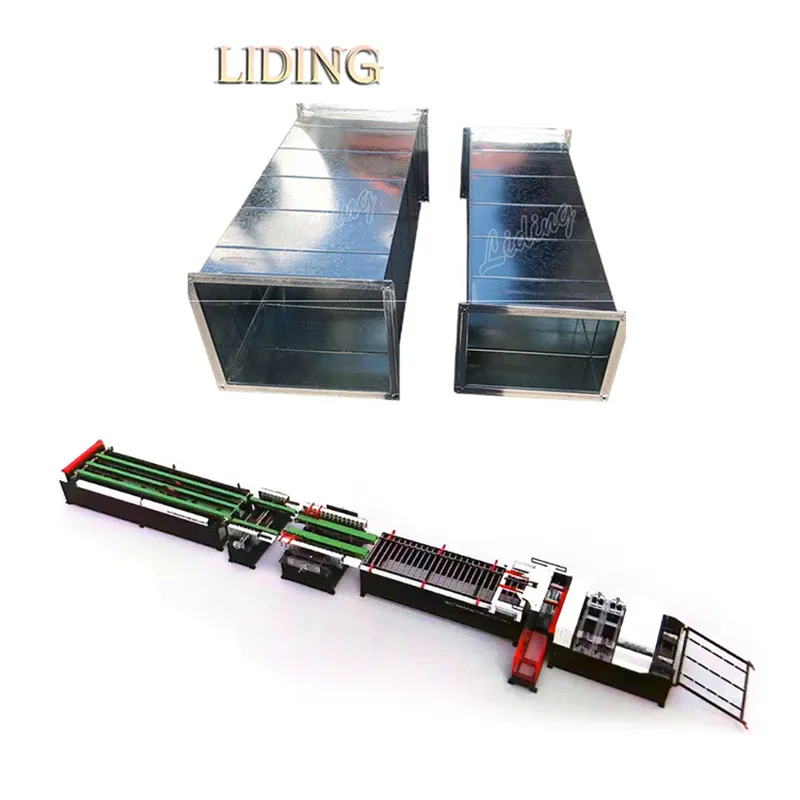

The advent of automated duct production lines has revolutionized the way ductwork is manufactured. These systems utilize advanced technology and robotics to automate various aspects of the production process, from cutting and forming to welding and assembly. The result is a highly efficient and accurate method of producing ductwork, with minimal human intervention required.

One of the key advantages of streamlining manufacturing processes with an automated duct production line is the significant reduction in labor costs. By automating repetitive and labor-intensive tasks, companies can eliminate the need for a large workforce, thereby saving a considerable amount of money in wages and benefits. This not only reduces operating expenses but also increases overall productivity, as machines can work around the clock without the need for breaks or shifts.

Furthermore, the use of an automated duct production line can result in improved product quality and consistency. With precise cutting and forming capabilities, these systems can produce ductwork with superior accuracy and reliability, ensuring that every piece meets the exact specifications and standards required. This level of consistency is difficult to achieve with manual labor and can lead to higher customer satisfaction and fewer product defects.

Another advantage of streamlining manufacturing processes with an automated duct production line is the ability to increase production capacity. These systems are designed to work at a much faster pace than traditional methods, allowing companies to fulfill orders in a shorter amount of time. Additionally, the flexibility and adaptability of automated duct production lines enable manufacturers to respond quickly to changes in demand, reducing lead times and improving customer service.

In addition to these benefits, the use of an automated duct production line can also lead to a safer and healthier work environment. By taking over tasks that are physically demanding or potentially hazardous, such as heavy lifting or exposure to fumes, machines can help reduce the risk of workplace injuries and illnesses for employees. This not only contributes to a better overall working atmosphere but also helps companies avoid costly downtime and workers’ compensation claims.

Lastly, the implementation of an automated duct production line can support companies in their pursuit of sustainability and environmental responsibility. By optimizing material usage and minimizing waste, these systems promote a more eco-friendly approach to manufacturing. Furthermore, the energy efficiency of automated machinery can lead to reduced power consumption, further reducing the carbon footprint of production operations.

In conclusion, the advantages of streamlining manufacturing processes with an automated duct production line are numerous and far-reaching. From cost savings and improved product quality to increased production capacity and enhanced workplace safety, the benefits of these systems are clear. As the manufacturing industry continues to evolve, companies that invest in automated duct production lines will be well-positioned to stay competitive and thrive in the market.

The successful implementation of automated duct production lines at various companies underscores the transformative impact of advanced technology on manufacturing processes. The efficiencies gained through automation, such as reduced labor costs, improved product quality, and streamlined operations, have proven to be instrumental in enhancing the competitiveness and profitability of these companies. As the manufacturing industry continues to evolve, the adoption of automated systems like the duct production line will be crucial for businesses seeking to stay ahead of the curve.

Are you ready to revolutionize your manufacturing processes and drive success and growth in the industry? The efficiency of an automated duct production line has proven to be a game-changer in streamlining manufacturing processes. With our 9 years of experience in the industry, we have witnessed firsthand the transformative power of automation in increasing efficiency, reducing costs, and improving overall production quality. We are committed to staying at the forefront of innovation and leveraging the latest technologies to deliver the best products to our customers.