The Efficiency Of An Auto Duct Line: Streamlining Ductwork Production

Looking to Revolutionize Your Ductwork Production? Embrace Automation for Enhanced Efficiency

If you're seeking to enhance the efficiency of your ductwork production, then look no further! In this article, we will delve into the advantages of utilizing an auto duct line and how it can streamline your ductwork production process. From increasing productivity to reducing labor costs, our comprehensive analysis will demonstrate the value of modernizing your production line. Continue reading to discover how an auto duct line can transform your business operations and take your productivity to new heights.

Recognizing the Significance of an Auto Duct Line in Ductwork Production

Efficiency in ductwork production is crucial in the HVAC industry, where the demand for high-quality ducts is continuously on the rise. One of the pivotal components in streamlining the production process is the integration of an auto duct line. This article aims to shed light on the significance of an auto duct line in ductwork production and how it contributes to the overall efficiency of the manufacturing process.

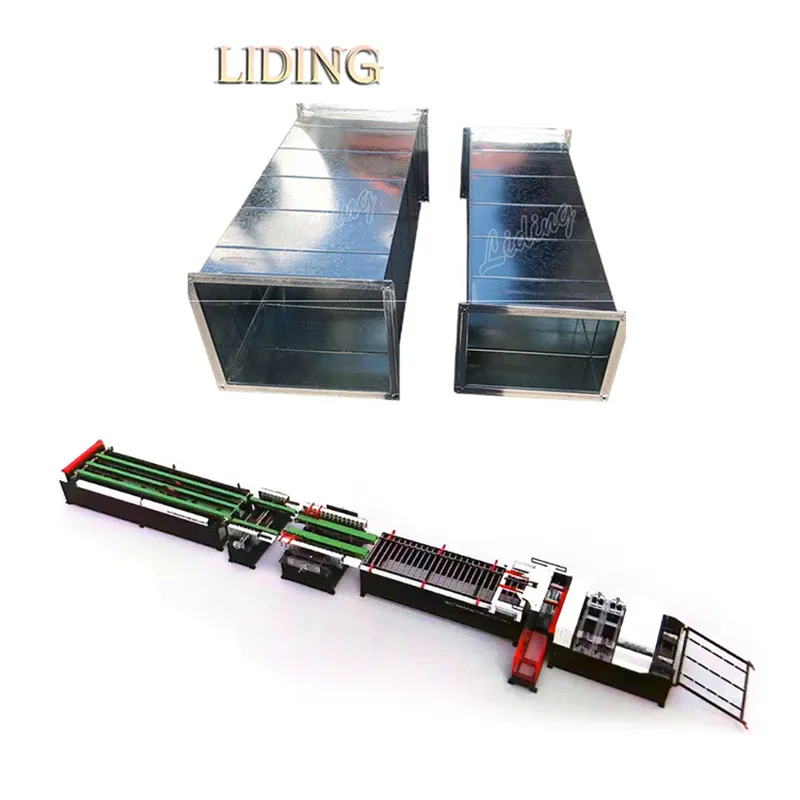

An auto duct line is a fully automated system designed to fabricate ductwork with precision and speed. It incorporates various machines and equipment such as a coil line, plasma cutting machine, TDF machine, and a CNC folder, all of which work seamlessly together to fabricate ducts of diverse shapes and sizes. The automation of the production process not only reduces the dependency on manual labor but also significantly enhances the accuracy and consistency of the final product.

One of the primary advantages of an auto duct line is its ability to produce ductwork at high speeds. With the capability to process metal coils at high speeds and cut, bend, and form the metal with precision, an auto duct line can generate a large volume of ducts in a relatively short amount of time. This is particularly beneficial in meeting tight deadlines and fulfilling large orders, which is common in the HVAC industry.

In addition to speed, an auto duct line also offers a high level of precision and accuracy in the fabrication of ductwork. The utilization of CNC technology ensures that the dimensions and angles of the ducts are consistently maintained, resulting in a final product that meets the strict specifications and standards of the industry. This precision is critical in ensuring that the ducts fit seamlessly into the HVAC systems they are intended for, ultimately improving the overall performance and efficiency of the system.

Furthermore, the automation of the production process through an auto duct line minimizes the margin of error, reducing the likelihood of rework and wastage of materials. This not only saves time and resources but also contributes to a more sustainable and cost-effective manufacturing process. With the reduction of human intervention in the fabrication process, the risk of injuries and accidents in the workplace is also significantly minimized, creating a safer environment for workers.

Another significant aspect of an auto duct line is the flexibility it offers in producing a wide range of ductwork. Whether it is rectangular ducts, spiral ducts, or custom-shaped ducts, the versatility of the machines within the auto duct line allows for the fabrication of diverse products to meet the varied needs of the market. This adaptability is crucial in catering to the specific requirements of different HVAC systems and applications.

In conclusion, the implementation of an auto duct line in ductwork production is instrumental in improving the efficiency, speed, precision, and flexibility of the manufacturing process. With the ability to produce a large volume of high-quality ducts in a shorter amount of time, an auto duct line not only streamlines the production process but also contributes to a more sustainable and cost-effective approach to ductwork fabrication in the HVAC industry.

Advantages of Streamlining Ductwork Production with an Auto Duct Line

In the HVAC fabrication sector, the adoption of an auto duct line has become increasingly popular due to its ability to streamline ductwork production. This advanced technology offers numerous advantages for manufacturers and fabricators, ultimately leading to increased efficiency and productivity.

One of the key advantages of using an auto duct line is its ability to automate the manufacturing process. This means that with minimal human intervention, the machine can carry out various tasks such as coil strip leveling, feeding, punching, notching, cutting, and bending. This automation significantly reduces the need for manual labor, thereby improving overall productivity and reducing the risk of human error.

In addition to automation, an auto duct line also offers greater precision and accuracy in the fabrication process. The use of advanced computer-controlled systems ensures that each duct component is produced to exact specifications, resulting in a higher level of consistency and quality. This not only enhances the overall performance of the ductwork but also minimizes wastage of materials, ultimately leading to cost savings for the manufacturer.

Furthermore, the speed at which an auto duct line can produce ductwork is unparalleled. By eliminating the need for manual handling and processing, the machine is capable of churning out duct components at a much faster rate, thereby increasing the overall output of the manufacturing process. This is particularly advantageous for manufacturers who are facing tight deadlines and high demand for their products.

Another significant advantage of streamlining ductwork production with an auto duct line is the reduction of labor costs. By automating many of the repetitive and labor-intensive tasks involved in duct fabrication, manufacturers can significantly reduce their reliance on manual labor, thus minimizing labor costs and increasing their bottom line.

Moreover, an auto duct line also brings about improvements in workplace safety. With the automation of various processes, the risk of workplace accidents and injuries associated with manual handling and processing is greatly reduced. This not only creates a safer working environment for employees but also reduces the potential for costly worker compensation claims.

From a broader perspective, the introduction of an auto duct line into a manufacturing facility can greatly enhance the overall competitiveness of the business. The increased efficiency and productivity resulting from the use of this advanced technology enable manufacturers to fulfill orders more quickly and at a lower cost, ultimately giving them a competitive edge in the market.

In conclusion, the advantages of streamlining ductwork production with an auto duct line are clear. By automating the manufacturing process, improving precision and accuracy, increasing production speed, reducing labor costs, enhancing workplace safety, and boosting overall competitiveness, this advanced technology offers numerous benefits for manufacturers and fabricators in the HVAC industry. As the demand for high-quality ductwork continues to grow, the use of an auto duct line will undoubtedly become a crucial asset for companies looking to stay ahead in the industry.

The Role of Automation in Increasing Efficiency and Precision in Ductwork Manufacturing

Ductwork manufacturing is a critical aspect of the HVAC industry, as ducts are essential for delivering conditioned air to different parts of a building. Traditionally, ductwork manufacturing has been a labor-intensive process, often prone to human error and inefficiencies. However, with the advent of automation technology, the landscape of ductwork production has been revolutionized. The introduction of auto duct lines has significantly increased efficiency and precision in the manufacturing process, leading to a higher quality end product and reduced production costs.

An auto duct line is a state-of-the-art automated system that is designed to streamline the production of ductwork. It consists of various components such as a coil line for material handling, a plasma cutting machine for precise cutting, a flange machine for forming edges, and a TDF machine for producing flanges. The entire process is controlled by advanced software that ensures seamless integration and coordination of all the machines. This level of automation has reduced the dependence on manual labor, thereby minimizing the risk of human error and guaranteeing consistency in the manufacturing process.

One of the key advantages of an auto duct line is the significant improvement in efficiency. The automated nature of the system allows for continuous production without the need for frequent pauses or breaks. This results in a higher output of ductwork within a shorter period. Additionally, the precision of the machines ensures that the final product meets the exact specifications required, reducing the need for rework and wastage of materials. This not only saves time but also reduces production costs, making the entire manufacturing process more economical.

Furthermore, the adoption of automation in ductwork manufacturing has led to an increase in the overall quality of the end product. The precision cutting and forming capabilities of the machines ensure that the ductwork is fabricated to the highest standards, with tight tolerances and accurate dimensions. This is essential for ensuring the proper functioning of the ducts in HVAC systems and contributes to the overall energy efficiency of the building. Additionally, the automated processes reduce the likelihood of defects or imperfections, resulting in a consistently high-quality output.

In addition to efficiency and precision, the implementation of auto duct lines has also had a positive impact on the working conditions of the employees involved in ductwork manufacturing. By automating the more labor-intensive and repetitive tasks, workers are able to focus on more complex and value-added activities, leading to a more fulfilling and less physically demanding work environment. This, in turn, contributes to higher employee satisfaction and retention, ultimately benefiting the overall productivity of the manufacturing facility.

In conclusion, the role of automation in increasing efficiency and precision in ductwork manufacturing cannot be overstated. The advent of auto duct lines has transformed the industry, leading to higher productivity, enhanced quality, and improved working conditions. As technology continues to advance, it is clear that automation will play an increasingly important role in shaping the future of ductwork manufacturing.

Maximizing Output and Minimizing Waste with an Auto Duct Line

In the modern era of manufacturing, efficiency is key. Businesses are constantly seeking ways to maximize output while minimizing waste. When it comes to the production of ductwork, this is no different. The utilization of an auto duct line has proven to be a game-changer in the industry, allowing for a more streamlined and efficient production process.

An auto duct line is a fully automated system that is designed to fabricate ductwork in a highly efficient manner. It eliminates the need for manual labor, significantly reducing the production time and labor costs associated with traditional fabrication methods.

One of the key benefits of an auto duct line is its ability to maximize output. By automating the fabrication process, the system can produce ductwork at a much faster rate than traditional methods. This increased output allows businesses to meet the demands of their customers more effectively and efficiently.

Additionally, an auto duct line is also designed to minimize waste. The precise nature of the automated system ensures that materials are used more efficiently, resulting in less waste and ultimately reducing costs for the business. This is not only beneficial from a financial standpoint but also environmentally, as it promotes sustainability and reduces the overall carbon footprint of the production process.

Another advantage of an auto duct line is its ability to improve the overall quality of the ductwork produced. The precise and consistent nature of the automated system ensures that every piece of ductwork is fabricated to the exact specifications, resulting in a higher-quality end product. This is crucial for businesses looking to maintain a reputation for superior quality and reliability.

From a financial perspective, the implementation of an auto duct line can lead to significant cost savings for businesses. By reducing labor costs, minimizing waste, and improving overall efficiency, businesses are able to increase their bottom line and remain competitive in the market.

Furthermore, the utilization of an auto duct line can also enhance the overall safety of the production process. With fewer manual processes involved, the risk of workplace accidents and injuries is significantly reduced, creating a safer working environment for employees.

In conclusion, the efficiency of an auto duct line in streamlining ductwork production cannot be overstated. From maximizing output and minimizing waste to improving overall quality and reducing costs, the benefits of implementing this automated system are numerous. As manufacturing continues to evolve, businesses that invest in innovative technologies such as auto duct lines are poised to succeed in the competitive market landscape.

The Future of Ductwork Production: Embracing Automation for Enhanced Efficiency

In today’s fast-paced and ever-evolving manufacturing industry, the future of ductwork production is heading towards embracing automation for enhanced efficiency. With the advancement of technology and the demand for increased productivity, the utilization of an auto duct line is becoming increasingly popular in streamlining ductwork production.

An auto duct line is a revolutionary system that integrates cutting-edge automation technology into the production process of ductwork. This advanced system is designed to automate various tasks such as cutting, bending, notching, and assembling ductwork components, ultimately reducing the reliance on manual labor and significantly improving overall productivity.

One of the key advantages of using an auto duct line is the enhanced efficiency it brings to the production process. By automating repetitive and labor-intensive tasks, manufacturers can achieve higher output rates with reduced labor costs, leading to increased profitability. The precision and accuracy of the automated system also result in improved product quality and consistency, benefiting both manufacturers and their customers.

Furthermore, the integration of automation into ductwork production allows for greater flexibility and adaptability to changing production demands. The auto duct line can be easily programmed to accommodate different ductwork designs and specifications, making it suitable for a wide range of products. This versatility enables manufacturers to meet the diverse needs of their customers, while also enabling them to quickly respond to market changes and trends.

In addition to efficiency and flexibility, the use of an auto duct line also contributes to a safer and healthier work environment. By taking over tasks that are traditionally carried out by manual labor, the risk of workplace injuries and accidents is significantly minimized. This not only ensures the well-being of workers but also helps to maintain a higher level of productivity without disruption.

As the demand for ductwork continues to grow, especially in industries such as HVAC, embracing automation through the use of an auto duct line becomes increasingly important for manufacturers to remain competitive in the market. The ability to produce ductwork at a faster rate and with higher precision gives companies an edge in meeting customer demands and staying ahead of the competition.

Furthermore, the long-term benefits of investing in an auto duct line are evident in the reduction of production costs and the overall improvement in operational efficiency. With a more streamlined production process, manufacturers can optimize their resources, minimize waste, and ultimately achieve a more sustainable and profitable business model.

In conclusion, the future of ductwork production lies in the embracing of automation through the utilization of an auto duct line. This innovative system offers numerous advantages, including enhanced efficiency, flexibility, safety, and cost-effectiveness. As technology continues to advance, manufacturers are presented with the opportunity to revolutionize their production processes and stay ahead in a highly competitive industry. Embracing automation is not just a choice, but a necessity for the continued growth and success of the ductwork production sector.

In conclusion, the efficiency of an auto duct line has revolutionized ductwork production in the HVAC industry. As a company with 9 years of experience in the field, we have witnessed the transformative impact of streamlining our production process through the implementation of an auto duct line. This technology has not only increased our productivity and output, but it has also allowed us to deliver high-quality ductwork to our clients in a timely manner. With the continuous advancement of technology, we are committed to staying at the forefront of innovation and embracing new opportunities to further improve our production processes. The efficiency of an auto duct line has truly been a game-changer for us, and we look forward to continuing to enhance our operations for years to come.