Revolutionizing Manufacturing: The Advantages Of Track Roll Forming Machines

“Transforming Your Manufacturing Processes with Track Roll Forming Machines

If you’re in search of ways to enhance your manufacturing processes and improve efficiency, then track roll forming machines may be the solution you've been looking for. In this article, we will be exploring the numerous benefits of utilizing these machines to optimize your production line and elevate your manufacturing capabilities. Whether you run a small business or a large corporation, track roll forming machines offer a plethora of advantages that can positively impact your bottom line. Keep reading to discover how these machines can revolutionize the way you conduct business.

I. to Track Roll Forming Machines

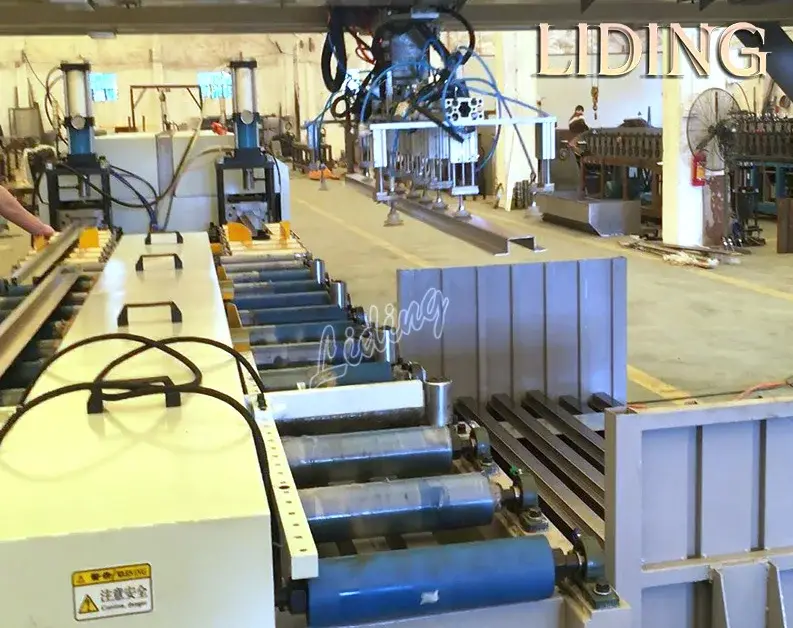

The advent of track roll forming machines has been groundbreaking in the manufacturing industry, and Liding Machine is leading the charge in this revolution. At Foshan Liding Technology Co., Ltd, we have been driving the development and production of track roll forming machines that are providing numerous benefits to manufacturers globally. In this article, we will delve into the introduction of track roll forming machines, exploring their functionality, advantages, and the impact they are making in the manufacturing sector.

So, what exactly are track roll forming machines? These machines are a type of rolling technology that is specifically designed for the continuous and high-volume production of complex, formed metal parts. The process involves feeding a strip of metal through a series of roll stands, where each stand performs a specific operation, gradually shaping the metal into the desired profile. Track roll forming machines are incredibly versatile, capable of producing a wide range of products such as tracks, channels, panels, and more.

At Foshan Liding Technology Co., Ltd, we have perfected the design and production of track roll forming machines to ensure maximum efficiency, precision, and consistency. Our machines are equipped with state-of-the-art technology, allowing for seamless integration into existing manufacturing processes. With customizable options and advanced control systems, our track roll forming machines are tailored to meet the unique needs of each customer, providing the versatility and adaptability required in today's dynamic market.

The advantages of track roll forming machines are manifold. Firstly, they offer unparalleled productivity and cost-effectiveness, as they can operate continuously, producing large quantities of parts with minimal downtime. This high-speed, high-volume production capability significantly reduces lead times and overall manufacturing costs, ultimately contributing to increased profitability for our customers.

Moreover, the accuracy and consistency achieved through track roll forming machines are unparalleled. The precision engineered roll stands ensure that each part is formed to exact specifications, meeting the highest quality standards. This level of consistency is essential for industries such as construction, automotive, and aerospace, where exacting tolerances are non-negotiable.

In addition to productivity and precision, track roll forming machines also offer flexibility and customization. With the ability to quickly switch between profiles and adjust tooling, manufacturers can adapt to changing market demands and produce a diverse range of products without the need for costly retooling or reconfiguration.

The introduction of track roll forming machines marks a significant evolution in the manufacturing landscape, and Liding Machine is at the forefront of this transformation. As we continue to push the boundaries of innovation and engineering, our track roll forming machines will undoubtedly play a pivotal role in revolutionizing the way metal parts are produced, setting new standards for productivity, quality, and efficiency.

II. Advantages of Track Roll Forming Machines in Manufacturing

The revolution in manufacturing processes has seen the rise of track roll forming machines as a critical tool in the production of various components and products. Foshan Liding Technology Co., Ltd has been at the forefront of this revolution, providing state-of-the-art track roll forming machines that offer numerous advantages to manufacturers.

One of the key advantages of track roll forming machines is their ability to produce high-quality, precise, and consistent products. Unlike traditional manufacturing methods, which often result in variations in product quality, track roll forming machines use advanced technology to ensure that every product meets strict quality standards. This level of precision is crucial in industries such as automotive and construction, where even the smallest deviation from specifications can lead to serious consequences.

Additionally, track roll forming machines offer significant time and cost savings. With the ability to produce large quantities of products in a shorter amount of time, manufacturers can streamline their production processes and meet demand more efficiently. This not only leads to increased profitability but also allows manufacturers to stay ahead of their competitors in a fast-paced market.

Another advantage of track roll forming machines is their versatility. These machines can be customized to produce a wide range of products, from simple components to complex shapes and designs. This flexibility is invaluable to manufacturers who need to adapt to changing market demands and produce a diverse array of products.

Furthermore, track roll forming machines are highly efficient in terms of material usage. By minimizing waste and optimizing material usage, manufacturers can reduce their environmental impact and contribute to sustainable manufacturing practices. This is an important consideration for companies looking to align with modern standards and meet the growing demand for eco-friendly products.

In addition to these benefits, track roll forming machines also offer improved workplace safety. By automating the production process, these machines reduce the need for manual labor in potentially hazardous tasks, such as heavy lifting and repetitive motions. This not only protects workers from injury but also improves overall productivity and employee satisfaction.

As a leading provider of track roll forming machines, Liding Machine has earned a reputation for delivering innovative, reliable, and cost-effective solutions to manufacturers worldwide. With a commitment to excellence and a dedication to pushing the boundaries of manufacturing technology, Liding Machine continues to be a driving force in the industry.

In conclusion, the advantages of track roll forming machines in manufacturing are numerous and far-reaching. From improved product quality and efficiency to cost savings and environmental sustainability, these machines are revolutionizing the way products are made. As the demand for high-quality, customizable, and sustainable manufacturing solutions continues to grow, track roll forming machines are set to play a vital role in shaping the future of the industry.

III. Cost and Time Efficiency of Track Roll Forming Machines

Track roll forming machines have revolutionized the manufacturing industry by providing cost and time efficiency for various industries. Foshan Liding Technology Co., Ltd (Liding Machine) leads the way in providing state-of-the-art solutions for businesses looking to streamline their production processes.

One of the key advantages of track roll forming machines is their ability to significantly reduce production costs. Traditional manufacturing methods often involve a high level of manual labor, which can be time-consuming and costly. However, track roll forming machines automate the process, allowing for higher production rates and lower labor costs. This is especially beneficial for businesses looking to increase their overall profitability and competitiveness in the market.

Furthermore, track roll forming machines are also incredibly time-efficient, offering quick turnaround times for businesses. The seamless integration of automation and precision engineering allows for rapid production of high-quality products, ultimately reducing lead times and improving overall operational efficiency. This is crucial for manufacturers looking to meet tight deadlines and fulfill large orders in a timely manner.

In addition to cost and time efficiency, track roll forming machines also offer a high level of flexibility and customization. These machines are capable of producing a wide range of products with varying shapes, sizes, and specifications, making them ideal for businesses with diverse production needs. This versatility allows manufacturers to cater to a wide range of customer demands, ultimately expanding their market reach and increasing their revenue potential.

Moreover, track roll forming machines are designed with advanced technology and quality materials, resulting in durable and reliable equipment. This not only minimizes the risk of production downtime but also ensures consistent and high-quality output, meeting the stringent standards of the manufacturing industry.

In conclusion, the cost and time efficiency of track roll forming machines have significantly transformed the manufacturing landscape, providing businesses with a competitive edge in today's market. Liding Machine, as a leading provider of track roll forming machines, continues to innovate and provide cutting-edge solutions for businesses looking to optimize their production processes. With their state-of-the-art technology and commitment to excellence, Liding Machine is a trusted partner for manufacturers seeking to revolutionize their manufacturing operations.

IV. Precision and Customization in Manufacturing with Track Roll Forming Machines

As the manufacturing industry continues to evolve, companies must strive to find more efficient and effective ways to produce high-quality products. This has led to the rise of track roll forming machines, which offer a level of precision and customization that was previously unattainable in traditional manufacturing processes.

At Foshan Liding Technology Co., Ltd, we have been at the forefront of this revolution, offering state-of-the-art track roll forming machines that are redefining the way products are manufactured. Our machines are designed to meet the unique needs of each customer, providing unparalleled levels of precision and customization.

One of the key advantages of track roll forming machines is their ability to produce complex, high-quality products with unmatched precision. Unlike traditional manufacturing processes, which often rely on manual labor and are prone to human error, track roll forming machines use advanced technology to ensure that each product is manufactured to exact specifications.

In addition to precision, track roll forming machines also offer a level of customization that was previously unattainable. Our machines are equipped with advanced software that allows customers to easily design and customize their products, tailoring them to their specific needs and requirements. Whether it's adjusting the dimensions of a product or adding unique features, our track roll forming machines can accommodate a wide range of customization options, giving manufacturers unprecedented control over the production process.

Furthermore, track roll forming machines are incredibly versatile, capable of producing a wide range of products across various industries. From automotive components to building materials, our machines can be customized to accommodate the specific needs of any manufacturing environment. This versatility not only makes track roll forming machines a cost-effective investment for manufacturers but also ensures that they can keep up with the ever-changing demands of the market.

At Foshan Liding Technology Co., Ltd, we are dedicated to providing our customers with the most cutting-edge track roll forming machines on the market. Our team of experts works closely with each customer to understand their unique needs and requirements, ensuring that our machines are tailored to their specific manufacturing processes. By prioritizing precision, customization, and versatility, we are helping manufacturers revolutionize their production processes and stay ahead of the competition.

In conclusion, track roll forming machines are revolutionizing the manufacturing industry by offering unprecedented levels of precision and customization. At Foshan Liding Technology Co., Ltd, we are proud to be at the forefront of this revolution, providing our customers with the most advanced and versatile track roll forming machines on the market. As the industry continues to evolve, we are committed to staying at the forefront of innovation, helping our customers meet the ever-changing demands of the market.

V. Future of Manufacturing: Integrating Track Roll Forming Machines into Production Lines

In the ever-evolving world of manufacturing, companies are constantly seeking ways to streamline their production processes and improve efficiency. As technology continues to advance, the integration of track roll forming machines into production lines has emerged as a game-changing solution. This innovative approach to manufacturing offers a wide range of advantages, making it a key component in the future of the industry.

At Foshan Liding Technology Co., Ltd, we have been at the forefront of the track roll forming machine revolution, providing cutting-edge solutions for our clients. Our track roll forming machines are designed to seamlessly integrate into existing production lines, offering a high level of flexibility and precision. With the ability to produce a wide range of profiles and components, these machines have become an essential tool for manufacturers across various industries.

One of the primary advantages of integrating track roll forming machines into production lines is the significant increase in efficiency. Traditional manufacturing methods often involve multiple processes and machinery, leading to longer production times and higher labor costs. With track roll forming machines, however, the entire production process is consolidated into a single, continuous operation. This streamlined approach not only reduces the time required to produce a finished product but also minimizes the risk of errors and defects.

In addition to efficiency, track roll forming machines also offer unparalleled versatility. Unlike traditional forming methods, which are often limited in terms of the types of profiles and components they can produce, track roll forming machines can accommodate a wide range of designs and specifications. This flexibility allows manufacturers to quickly adapt to changing market demands and produce a diverse range of products without the need for costly tooling changes.

Moreover, the precision and consistency offered by track roll forming machines are unmatched by traditional forming methods. By utilizing advanced control systems and automated processes, these machines are capable of producing components with extremely tight tolerances, ensuring a high level of quality and repeatability. This level of precision not only enhances the overall quality of the finished product but also reduces the amount of material waste, leading to cost savings for manufacturers.

As the manufacturing industry continues to evolve, the integration of track roll forming machines into production lines will undoubtedly play a crucial role in shaping its future. At Foshan Liding Technology Co., Ltd, we are committed to driving this evolution forward and providing our clients with the tools they need to succeed in an increasingly competitive market. With our state-of-the-art track roll forming machines, manufacturers can expect to see improvements in efficiency, versatility, and overall quality, setting the stage for a new era of manufacturing excellence.

In conclusion, track roll forming machines are truly revolutionizing the manufacturing industry, offering a wide range of benefits such as increased efficiency, precision, cost-effectiveness, and versatility. With our 9 years of experience in the industry, we have seen firsthand the positive impact that these machines have had on production processes and ultimately, on the success of businesses. As technology continues to advance, we can expect even further developments in track roll forming machines, further revolutionizing the manufacturing industry and opening up new possibilities for businesses around the world.”