Find Your Perfect Roll Forming Machine For Sale Today

Are you in the market for a high-quality roll forming machine? Look no further! Our comprehensive guide will help you navigate the options and find the perfect roll forming machine for sale today. From selecting the right specifications to ensuring a reliable and efficient investment, we've got you covered. Keep reading to find out everything you need to know to make an informed decision about your next roll forming machine purchase.

- Understanding Roll Forming Machines and Their Uses

If you are in the market for a roll forming machine for sale, it is important to understand the different types of machines available and their uses. Roll forming machines are a vital part of the manufacturing industry, used to create complex metal shapes and profiles with precision and efficiency. Understanding the different types of roll forming machines and their uses can help you find the perfect machine for your specific production needs.

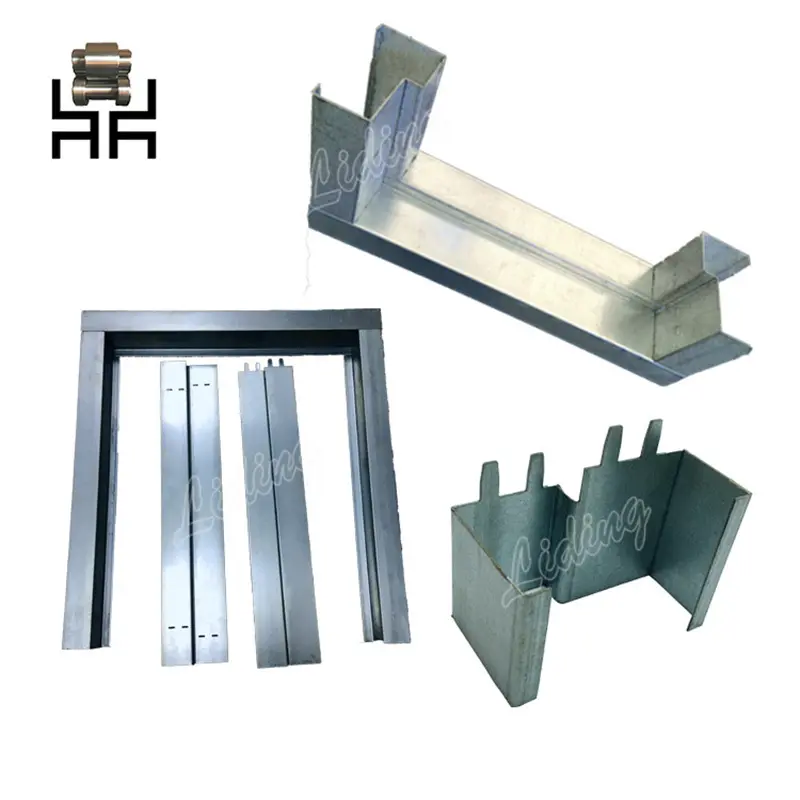

There are several different types of roll forming machines, each designed for specific applications. Some common types of roll forming machines include the standard roll former, the standing seam roll former, the hat channel roll former, and the purlin roll former. Each of these machines is designed to produce different types of metal profiles and shapes, making it important to choose the right machine for your specific production requirements.

The standard roll former is the most common type of roll forming machine and is used to create a wide variety of metal profiles and shapes. This versatile machine can be used to produce everything from simple angles and channels to complex and intricate profiles. The standing seam roll former, on the other hand, is specifically designed to create standing seam roofing panels, while the hat channel roll former is used to produce hat channel profiles for use in construction and other industries. The purlin roll former is designed to create purlins, which are horizontal structural members used in the construction of buildings.

In addition to understanding the different types of roll forming machines, it is also important to consider the specific features and capabilities of each machine. Roll forming machines can vary widely in terms of the materials they can handle, the complexity of profiles they can produce, and the speed and efficiency of their operation. Some machines may also offer additional features such as automatic stacking and packaging, which can help streamline the production process and improve overall efficiency.

When searching for a roll forming machine for sale, it is important to consider your specific production requirements and the capabilities of the machines you are considering. If you are working with a wide range of materials and need to produce complex profiles, you may need a more versatile and high-capacity machine. On the other hand, if you have specific production needs such as standing seam roofing panels or purlins, you may need a machine that is specifically designed for those applications.

Ultimately, finding the perfect roll forming machine for sale requires a thorough understanding of the different types of machines available and their uses. By considering your specific production requirements and the capabilities of the machines you are considering, you can find a machine that meets your needs and helps you improve the efficiency and quality of your production process. Whether you are a small manufacturing shop or a large-scale production facility, finding the right roll forming machine is essential for achieving success in the metalworking industry.

- Factors to Consider When Choosing a Roll Forming Machine

When it comes to finding the perfect roll forming machine for sale, there are several factors to consider before making a purchase. Roll forming machines are an essential piece of equipment in many industries, such as construction, automotive, and aerospace, and choosing the right machine is crucial to the success of your business. In this article, we will explore the key factors to consider when selecting a roll forming machine for sale, and provide you with the information you need to make an informed decision.

First and foremost, it is important to consider the specific requirements of your production process when choosing a roll forming machine. This includes the type of material you will be working with, the thickness and width of the material, and the desired output speed. Different roll forming machines are designed to handle different materials and production volumes, so it's important to choose a machine that is well-suited to your needs.

Another important factor to consider is the level of automation and customization that you require from your roll forming machine. Some machines are fully automated and offer a high degree of customization, while others are more basic and require more manual intervention. The level of automation and customization that you need will depend on the complexity of your production process and the level of precision and consistency that you require in your products.

The size and space requirements of your production facility should also be taken into consideration when choosing a roll forming machine for sale. Some machines are large and require a significant amount of space, while others are more compact and can be easily integrated into smaller production facilities. It's important to carefully assess the space available in your facility and choose a machine that fits within your constraints.

In addition to the technical specifications of the machine, it's important to consider the reputation and reliability of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality, reliable machines. A well-established manufacturer is more likely to provide you with reliable customer support and access to spare parts and maintenance services, which is crucial for the long-term success of your production process.

Finally, it's important to consider the cost of the roll forming machine and its long-term return on investment. While it's important to stay within budget, it's also crucial to avoid cutting corners on quality in order to save money. Consider the total cost of ownership, including maintenance and operating costs, as well as the potential increase in productivity and product quality that the machine can bring to your business.

In conclusion, finding the perfect roll forming machine for sale requires careful consideration of a variety of factors, including the specific requirements of your production process, the level of automation and customization that you need, the space available in your facility, the reputation and reliability of the manufacturer, and the cost and long-term return on investment. By taking these factors into account, you can make an informed decision and find a roll forming machine that is well-suited to your business's needs.

- Exploring Different Types of Roll Forming Machines

Roll forming is a widely used manufacturing process that involves passing a metal strip through a series of roll forming stands to gradually shape the metal into a desired profile. In the market today, there is a wide variety of roll forming machines for sale, each with its own unique capabilities and features. In this article, we will explore the different types of roll forming machines available and help you find the perfect machine for your specific needs.

1. Standard Roll Forming Machines:

Standard roll forming machines are the most common type of roll forming equipment and are used to produce a wide range of simple, straight profiles such as channels, angles, and tubes. These machines typically consist of a series of roll forming stands, where each stand gradually shapes the metal into the desired profile. Standard roll forming machines are ideal for high-volume production of simple profiles and are often used in industries such as construction, automotive, and appliance manufacturing.

2. Custom Roll Forming Machines:

Custom roll forming machines are designed to produce complex, custom-designed profiles that cannot be produced on standard roll forming machines. These machines are often equipped with additional features such as pre-punching, notching, and embossing to create unique and intricate profiles. Custom roll forming machines are widely used in industries such as aerospace, architecture, and agricultural equipment manufacturing, where specialized profiles are required.

3. Portable Roll Forming Machines:

Portable roll forming machines are designed for on-site roll forming applications, where transportation of large metal coils is impractical. These machines are lightweight and compact, making them easy to transport to job sites. Portable roll forming machines are commonly used in the construction industry for producing metal roofing and siding panels on-site, eliminating the need for pre-formed panels and reducing transportation costs.

4. Double-Headed Roll Forming Machines:

Double-headed roll forming machines have the capability to produce two profiles simultaneously, increasing production efficiency and reducing material waste. These machines are equipped with two sets of roll forming stands, each dedicated to producing a specific profile. Double-headed roll forming machines are commonly used in industries where multiple profiles are required for a single product, such as garage door manufacturing and shelving systems.

5. Electrically Driven Roll Forming Machines:

Electrically driven roll forming machines utilize electric motors to drive the roll forming stands, providing precise control over the forming process. These machines are ideal for producing high-quality, consistent profiles, and are often used in industries where tight tolerances are required, such as automotive and aerospace manufacturing.

In conclusion, the choice of roll forming machine for sale depends on the specific requirements of your production process. Whether you need a standard machine for high-volume production, a custom machine for complex profiles, a portable machine for on-site applications, or a double-headed machine for increased efficiency, there is a roll forming machine available to meet your needs. By understanding the different types of roll forming machines and their capabilities, you can make an informed decision and find the perfect machine for your production needs.

- Evaluating the Quality and Efficiency of Roll Forming Machines

Finding the perfect roll forming machine for sale today requires a comprehensive understanding of the quality and efficiency of different machines on the market. With the growing demand for roll forming machines in various industries, it has become crucial for businesses to invest in the right equipment that can meet their production needs with high efficiency and output quality.

When evaluating the quality of a roll forming machine for sale, there are several key factors to consider. The first and most important aspect is the machine's build and construction. A high-quality roll forming machine should be built with durable materials and precision engineering to ensure long-term reliability and performance. Look for machines that are made with high-grade steel and advanced manufacturing techniques to guarantee durability and stability during operation.

In addition to the machine's build, it is essential to assess its technological features and capabilities. Advanced roll forming machines are equipped with modern control systems and automation technology to optimize production processes and ensure consistent and accurate forming of metal profiles. Look for machines that offer a wide range of customization options and flexibility in adjusting forming parameters to accommodate different material types and thicknesses.

Efficiency is another critical aspect to consider when searching for a roll forming machine for sale. An efficient machine will not only increase productivity but also reduce production costs and lead times. Look for machines that offer high-speed production capabilities without compromising on the quality of the formed profiles. Energy efficiency is also a key consideration, as it can significantly impact operating costs over the lifespan of the machine.

When evaluating the efficiency of a roll forming machine, it is important to assess its overall production capacity and output quality. The machine should be able to consistently produce high-quality profiles with minimal material waste and downtime. Look for machines that offer quick changeover capabilities and easy maintenance procedures to maximize uptime and overall equipment effectiveness.

Furthermore, consider the manufacturer's reputation and track record in the industry when selecting a roll forming machine for sale. Reputable manufacturers with a history of producing reliable and high-performing machines are more likely to deliver a quality product that meets your production needs. Look for customer reviews and testimonials to gauge the satisfaction and success of other businesses that have invested in the same machine.

In conclusion, finding the perfect roll forming machine for sale involves a thorough evaluation of its quality and efficiency. Consider factors such as build quality, technological features, efficiency, and the manufacturer's reputation when making your decision. By investing in a high-quality and efficient roll forming machine, businesses can ensure seamless production processes and achieve superior output quality for their metal forming needs. With careful consideration and research, businesses can find the ideal machine that will deliver long-term value and performance.

- Where to Find and Purchase the Best Roll Forming Machine for Your Needs

Roll forming machines are an essential piece of equipment for various industries, providing a cost-effective and efficient method for shaping metal sheets into various shapes and profiles. Whether you are in the construction, automotive, or manufacturing industry, finding the perfect roll forming machine for sale is crucial to meeting your production needs.

When it comes to finding and purchasing the best roll forming machine for your needs, there are several factors to consider. From the type and size of the machine to the supplier and cost, it's important to do thorough research to ensure you are getting the perfect roll forming machine for sale.

One of the first steps in finding the perfect roll forming machine for sale is determining the type and size of the machine that best suits your production needs. Roll forming machines come in various types, including C-channel machines, Z Purlin machines, and stud and track roll forming machines, each designed for specific applications. Additionally, considering the size and capacity of the machine is crucial to ensure it can handle the volume of production you require.

Once you have determined the type and size of the roll forming machine you need, the next step is to find a reputable supplier. When searching for a roll forming machine for sale, it's important to choose a supplier with a proven track record of providing high-quality machines and excellent customer service. Look for suppliers who offer a wide range of roll forming machines and have experience working with businesses in your industry.

When it comes to cost, finding a roll forming machine for sale that fits within your budget is crucial. However, it's essential to balance cost with quality to ensure you are getting a machine that will meet your production needs and stand the test of time. Consider the long-term return on investment when making your decision, as a higher upfront cost for a high-quality machine may result in lower maintenance and repair costs down the line.

In addition to the type, size, supplier, and cost of the machine, it's also important to consider factors such as the machine's features, technical specifications, and any additional services or support offered by the supplier. Look for machines with advanced features that will enhance the efficiency and performance of your production process, and consider the technical specifications to ensure the machine meets your exact requirements.

When it comes to purchasing a roll forming machine for sale, there are several options available, ranging from purchasing new machines directly from a supplier to buying used or refurbished machines. Each option has its own advantages and considerations, so it's important to carefully weigh your options and choose the best fit for your business.

In conclusion, finding the perfect roll forming machine for sale requires careful consideration of the type, size, supplier, cost, features, and purchasing options. By conducting thorough research and working with a reputable supplier, you can find the ideal roll forming machine to meet your production needs and help your business thrive in its industry.

Conclusion

In conclusion, finding the perfect roll forming machine for sale today is easier than ever, thanks to the expertise and experience of our company. With 9 years in the industry, we understand the unique needs and challenges of our customers and strive to provide the best solutions. Whether you are in need of a standard roll forming machine or a custom solution, we have the knowledge and resources to help you find the perfect machine for your business. Contact us today to learn more about our offerings and how we can help you streamline your production processes. Don't wait any longer to upgrade your equipment and improve your bottom line.