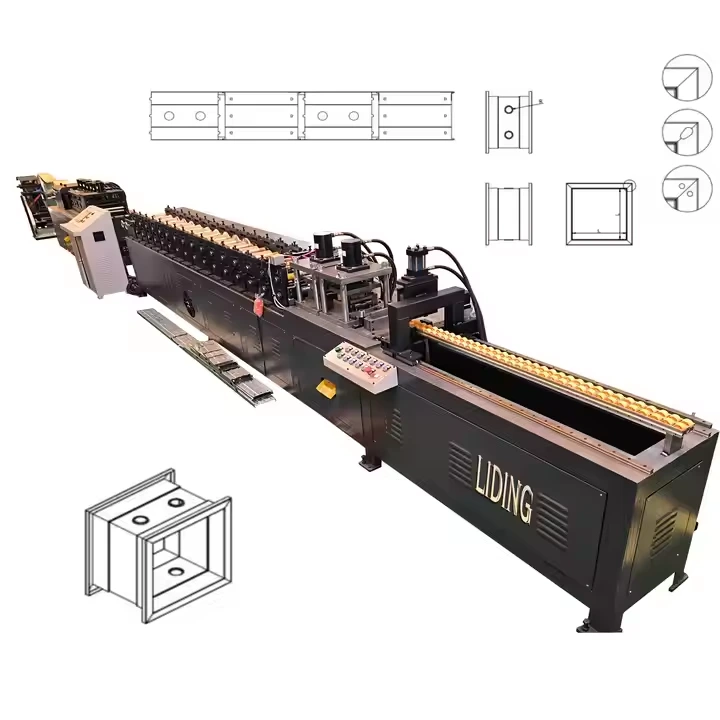

VCD-Volume control damper frame roll forming machine

Application:

-

Commercial HVAC systems

-

Industrial ventilation

-

Fire/smoke damper production

-

Custom air control solutions

Main features

Volume control damper frame Roll Forming Machine Key Advantages:

✔ Full Automation – Minimize labor costs while maximizing output

✔ High-Speed Production – Form up to 10 meters/minute without compromising accuracy

✔ Multi-Stage Process – Integrated punching, notching and roll forming in one continuous operation

✔ Precision Engineering – ±0.2mm tolerance for perfect damper frame alignment

Damper outer frame roll forming Machine Main Technical Parameters

|

Technical parameters and specifications |

|

|

Coil material |

Galvanized Sheet |

|

Material thickness |

1.0-1.6mm |

|

Inner/Outer diameter of coil |

Ф460-Ф520mm/1500mm |

|

Forming speed |

6-10m/min |

|

8, Sheet length error range |

± 0.5mm |

|

Valve body bending error range |

±0.5mm |

|

Control system |

Full computer numerical control |

|

Main power supply |

380V 50Hz 3-phase |

|

Hydraulic pressure Working pressure |

8-12 MPa |

|

system pressure |

16MPa |

|

Pneumatic pressure |

0.6-0.8MPa |

|

Total length of the production line |

About 20 meters |

|

Machine width |

Approx. 1 m |

|

Total power |

About 25KW |

|

Total weight of machinery |

about 8 tons |

Workflow

Damper outer frame forming Producing process:

Decoiling →Servo Feeding& Punching&Cutting → Roll forming →Punching & Cutting→Run-out table

Damper outer frame roll forming Machine Compositions

|

Item |

Date |

|

Decoiler and leveling two-in-one machine |

Load weight 3000kg |

|

NC precision electronic numerical control roller feeding machine |

2KW servo motor |

|

Hydraulic punch&Cutting Modular |

Round hole punching molds 1 sets |

|

Roll Forming Machine |

16 stations, 7.5KW servo motor |

|

Hydraulic punch modular after forming |

2 Stations,with 2 mold |

|

Cutting Modular after forming |

1 Station,with 1 mold |

|

Run Out Table |

4 m |

|

PLC control cabinet |

Famous brand with touch screen |

|

Hydraulic system |

2 set (5.5kw) |

Youtube Video List

Volume Control Damper (VCD) Frame Roll Forming Machine

Product display