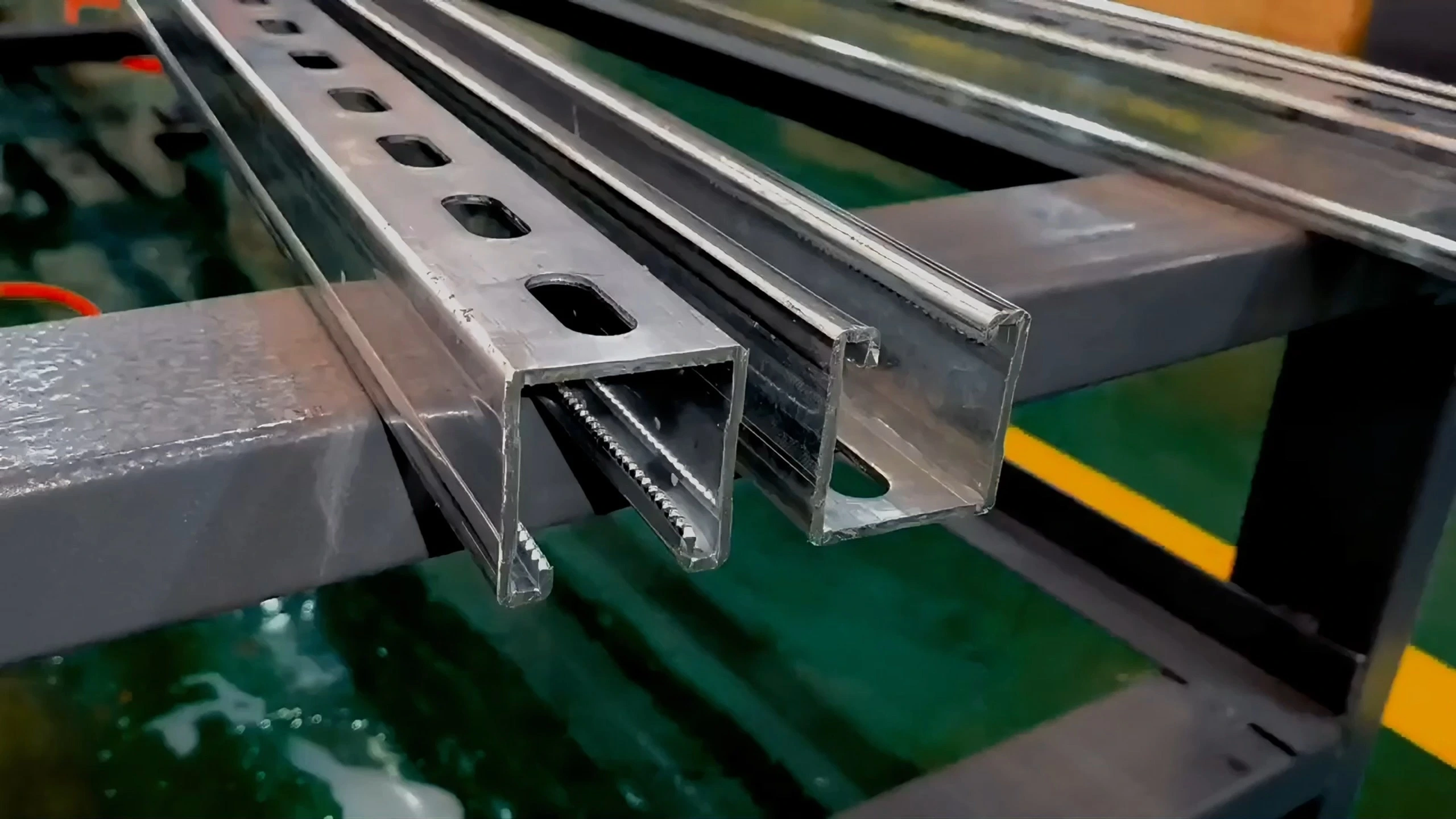

Solar Bracket U Channel Forming Machine HVAC Slotted Unistrut Channel Roll Forming Machine

Технические характеристики: машина может производить : 41 * 21, 41 * 41 две спецификации

толщина материала : 1,5-3,0 мм

Profile

애플리케이션

Workflow

Electric decoiling and leveling feed - servo feed - punching and punching teeth - cold roller forming - hydraulic cutting - unloading - finish

Composition of the machine

the whole line is about 24 meters long

● Electric leveling Decoiler(2T),1 set

● Servo feeder,1 set

● Hydraulic punching machine,1 set

● Punching molds (41*21, 41*41),2 sets

● Forming machine,1 set

● Hydraulic cut-off mold ,1 set

● Run-out table,1 set

● PLC control cabinet 1 set

Basic Configuration

Electric leveling Decoiler

● Bore diameter 460~520mm.

● Material width 300mm.

● Load weight 2000kg.

● Manual core expansion is used.

● With power transmission .

● Automatic control function.

NC precision electronic numerical control roller feeding machine

● Material width: 200mm.

● Material thickness: 3.0mm.

● Servo motor:AC1.8KW.

● Feeding speed: 10 meters/min.

Hydraulic punching machine 1 set, punching mold 2 sets

● Hydraulic working pressure:16MPA

● Hydraulic motor:7.5KW

● Material width 102-142mm.

● Material thickness 1.5-3.0mm.

● Mold material Cr12MoV.

Basic Configuration

Molding machine

● Applicable materials: Cold or galvanized sheet metal

● Material thickness:1.5-3.0mm.

● Machine can produce 41*21, 41*41 two specifications, lifting forming module replacement specifications

● Main motor power: 22kw (two motors total 22kw).

● Forming speed: 0-6m/min.

● Bearing: NJ210E Bearing

● Number of forming groups: 21 groups (14 groups for replacement specifications)

● Shaft diameter and material: ¢58mm, 45# steel.

● Tolerance of cut length: 3m+-1.5mm, (cut between hole and hole).

● Transmission: Chain, gearbox steering transmission (Main drive reduction gearbox: BWD4).

● Control system: PLC control.

● Machine net weight: about 8 tons .

● Voltage: 380V/ 3phase/ 50 Hz.

● Dimensions of forming machine: Approx L*W*H 7m*1m*1.4m (Frame welded with steel pipe)

● Forming roll material: Cr12MoV.

● Cutting mold material: Cr12MoV Heat treatment HRC60-62℃.

Basic Configuration

Cutting off parts

● Equipped with a set of hydraulic system unit.

● With two sets of mold cut-off.

● Motor power 4 kW.

● Adopt cylinder control cut-off method.

● Adoption of non-stop cylinder jack cut-off method

Unloading

● Flat length 4 meters

● Flat table structure using square tube angle iron composition.

● Pneumatic automatic unloading is adopted.

PLC computer control box

● Voltage: 380 V, 50 Hz, 3Phase

● Automatic length measurement of punched holes: servo motor

● Automatic measurement: encoder

● Control the length and quantity with PLC The machine automatically cuts the length and stops when the required quantity is reached.

● Length can be modified

● Control panel: push-button switches, touch screen

제품 디스플레이

Линия по производству воздуховодов HVAC

—Машина для изготовления фланцев

Линия по производству противопожарных клапанов

Профилегибочная машина для производства прогонов C/U/Z

—Машина для изготовления дверей и окон

—Профилегибочная машина для производства стеллажей

—Машина для производства металлических шпилек и гусеничных роликов

—Профилегибочная машина для производства направляющих рельсов